Longwall shearer or other machine with a gear case for transmitting rotational power

A technology for coal shearers and gearboxes, applied in gear lubrication/cooling, slitting machinery, earthwork drilling and mining, etc. It can solve the problems of internal lubricating oil water pollution, water and dust ingress pollution, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

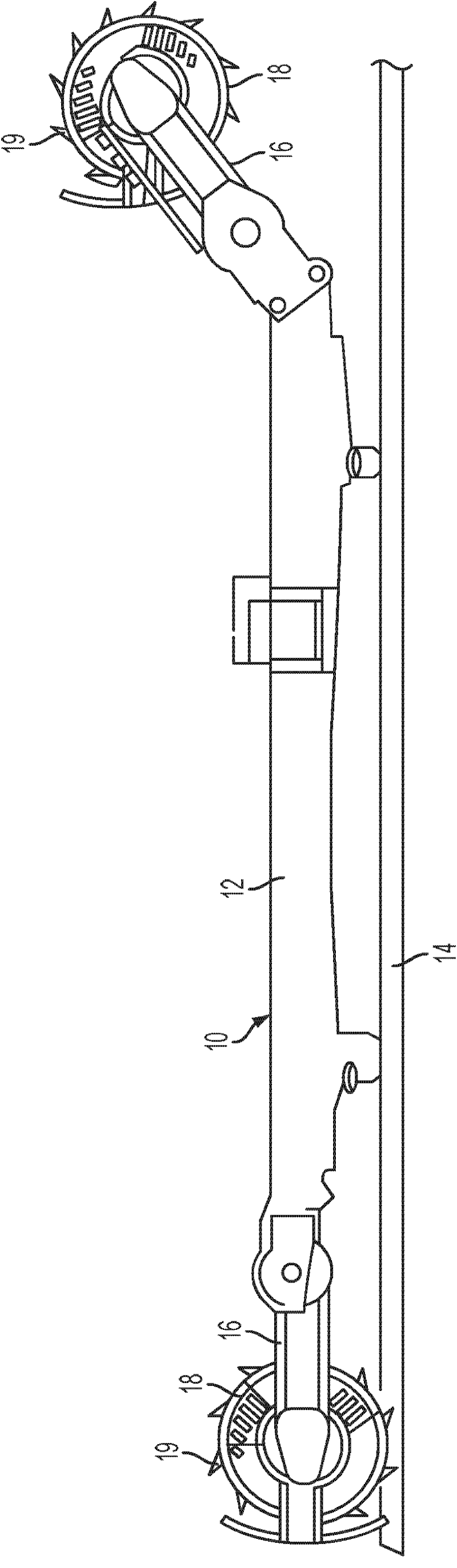

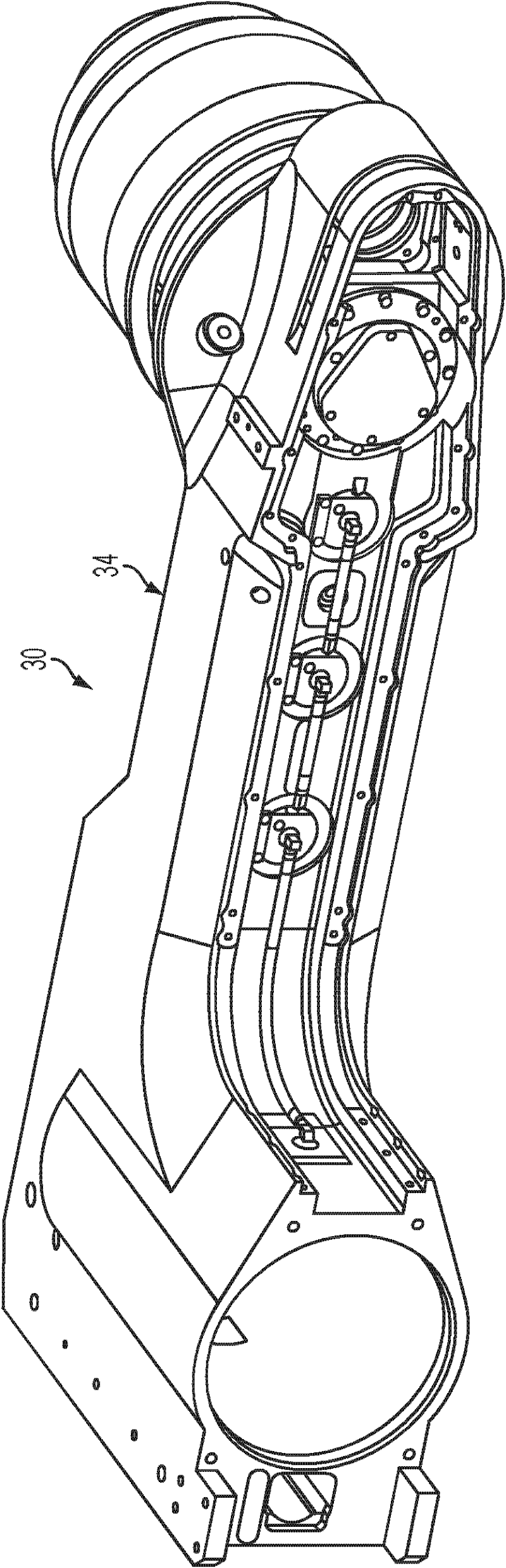

[0032] A preferred embodiment involves figure 1 A modification of the rocker arm 16 is shown. More specifically, the improved rocker arm 30 such as Figures 2 to 4 shown.

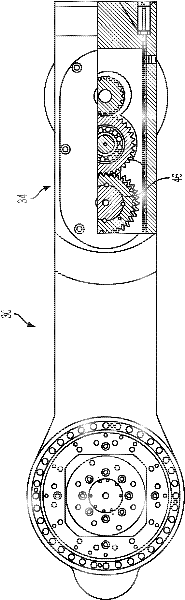

[0033] Such as Figure 4 As shown, the disclosed longwall shearer rocker arm 30 includes a gearbox 34 for transferring rotational power from a drive 38 to the rotationally driven toothed drum 18 . The gearbox 34 includes an elongated housing 42 and a plurality of single gears 46 mounted in a row within the elongated housing 42 . One gear at one end of the row is drivingly connected to the driver 38 and the other gear at the other end of the row is drivingly connected to a driven member, which is the drum 18 . The mount for each single gear is in the form of a longitudinal gear shaft 50 having a mounting axis extending longitudinally along the gear shaft 50 and lubricating oil 54 surrounding the single gear 46 and contained in the housing 42 Inside.

[0034] The present invention proposes a new cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com