Highly dispersed graphene sheet composite material regularly modified by metal nanodot and in-situ preparation method

A technology of metal nano and graphene sheets, applied in the direction of graphene, nano carbon, non-metallic elements, etc., can solve the problems of size, regularity, density control, etc., and achieve the effect of small dispersion and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

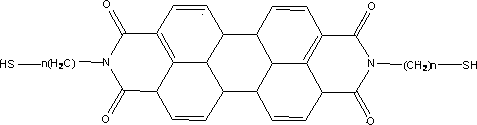

[0032] (1) The steps of the preparation method of N,N'-di(2-mercaptoethyl)peryleneimide derivative molecule containing mercapto group are as follows:

[0033] (a) Add 1 part by weight of 3,4,9,10-perylenetetracarboxylic dianhydride, 0.5 part by weight of mercaptoamine molecules and 1 part by weight of anhydrous zinc acetate into 10 mL of quinoline, and stir at 100 ° C under the protection of N2 Reaction for 3 hours;

[0034] (b) adding the reaction solution to 500 mL of dehydrated ethanol for precipitation, collecting the filter residue by filtration, washing the filter residue 3 times with a 5% sodium hydroxide solution by weight percentage concentration, and filtering until the filtrate is colorless;

[0035] (c) The filter residue was washed with deionized water until the pH value of the filtrate became neutral, and dried in a vacuum oven at 70°C to obtain N,N'-bis(2-mercaptoethyl)peryleneimide molecules.

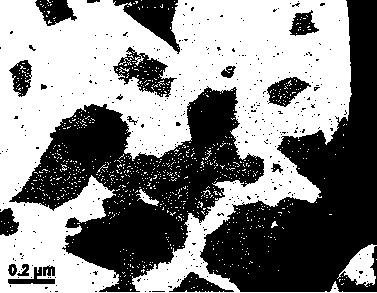

[0036] (2) Preparation of N,N'-bis(2-mercaptoethyl)peryleneimide m...

Embodiment 2

[0042] (1) The steps of the preparation method of N,N'-di(2-mercaptoethyl)peryleneimide derivative molecule containing mercapto group are as follows:

[0043] a) 1 part by weight of 3,4,9,10-perylenetetracarboxylic dianhydride, 1 part by weight of 2-mercaptoethylamine and 1 part by weight of anhydrous zinc acetate were added to 20 mL of quinoline, and stirred at 150 °C under the protection of N2 Reaction for 12 hours;

[0044] b) Add the reaction solution to 1000mL of absolute ethanol for precipitation, collect the filter residue by filtration, wash the filter residue with 10% sodium hydroxide solution by weight for 5 times, and filter until the filtrate is colorless;

[0045] c) The filter residue was washed with deionized water until the pH value of the filtrate became neutral, and dried in a vacuum oven at 70°C to obtain N,N'-bis(2-mercaptoethyl)peryleneimide molecules.

[0046] (2) Preparation of N,N'-bis(2-mercaptoethyl)peryleneimide molecularly modified graphene sheets: ...

Embodiment 3

[0052] (1) The steps of the preparation method of N,N'-bis(2-mercaptododecyl)perylimide containing mercapto group are as follows:

[0053] Except that the raw material uses mercaptododecylamine instead of thioglycolic acid, other experimental procedures are the same as in Example 1.

[0054] (2) Preparation of N,N'-bis(2-mercaptododecyl)peryleneimide molecularly modified graphene sheets: In addition to the reaction raw materials, use N,N'-bis(2-mercaptododecyl)perylene The experimental procedure is the same as in Example 1 except that imide is used instead of N,N'-bis(2-mercaptoethyl)peryleneimide.

[0055] (3) Preparation of gold nanodot-modified graphene sheet: the experimental procedure is the same as in Example 1. The transmission electron microscope confirmed that the aqueous solution of the graphene sheet nanocomposite material regularly decorated with gold nanodots was obtained with high dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com