Vibration isolation system of vibrating centrifuge

A technology for vibrating centrifuges and vibration isolation systems, applied in centrifuges and other directions, can solve problems such as the resonance of the rotating arm system, the reduction of the reliability of the centrifuge system, and the design of the natural frequency of the leaf spring, and achieve high static stiffness, light weight, dynamic Effects of small stiffness and natural frequencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

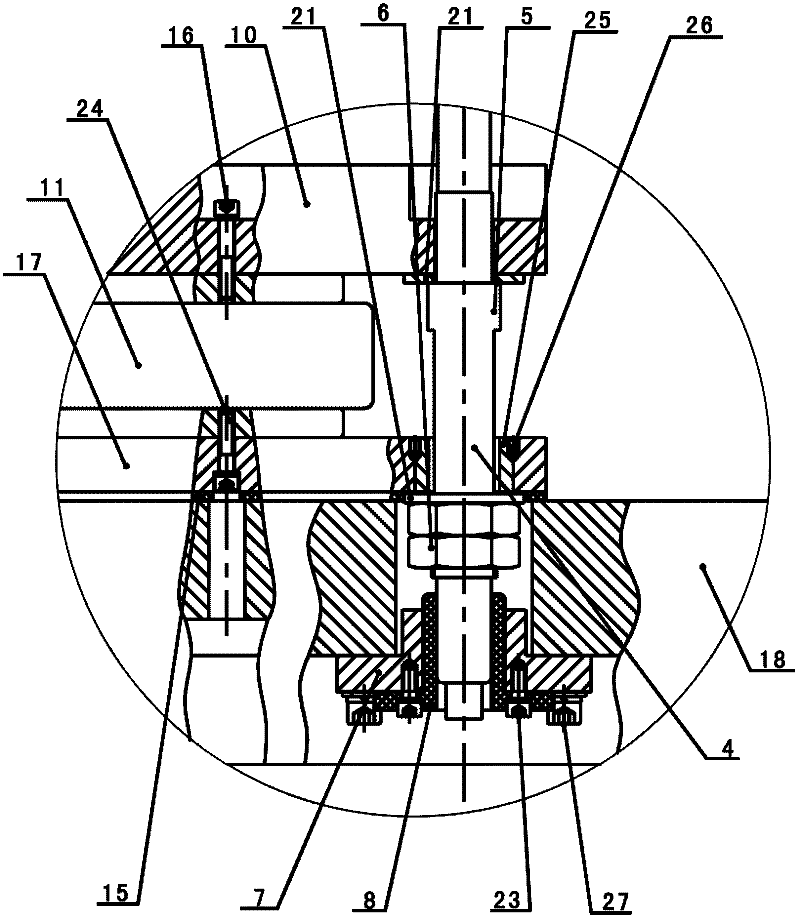

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0031] Such as figure 1 As shown, the present invention includes two sets of vibration isolation devices 3 with the same structure, and the two sets of vibration isolation devices 3 are symmetrically installed on the swing arm system support 2 on both sides of the swing arm support 1 of the vibrating centrifuge, and the swing arm system support 2 is on the When working, it will slide in both directions relative to the arm support 1 (such as figure 1 indicated by the middle arrow).

[0032] Such as Figure 1-Figure 7As shown, each set of vibration isolation device 3 includes a force sensor 14, an upper rigid plate 10, a middle rigid plate 17, a lower rigid plate 18, a guide rod 4, a linear bearing 8, an adjustment block 7 and an air spring 11, to The axial direction of the guide rod 4 is the up-down direction, the upper end of the guide rod 4 is connected with the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com