Automatic sample replacing device

A technology of automatic sample changing and driving device, applied in the direction of analyzing materials, instruments, etc., can solve the problems of long sampling time, long waiting time, manual manual replacement, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be further described in detail below.

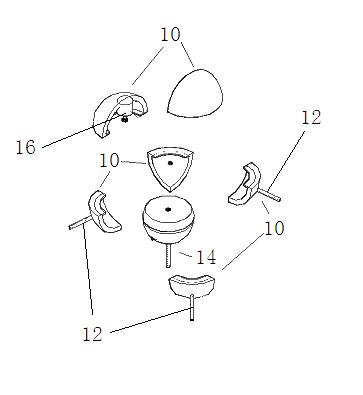

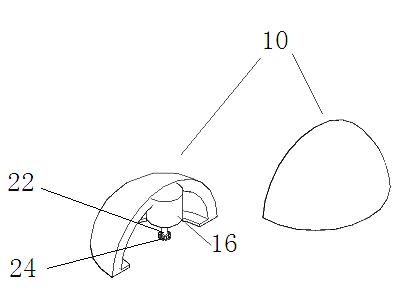

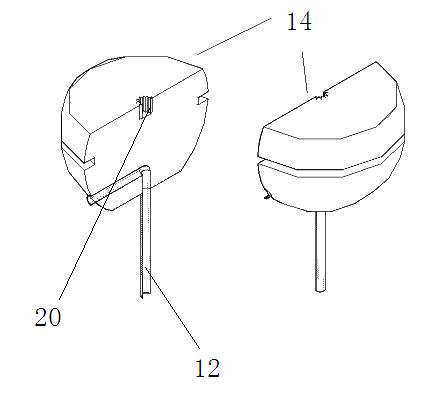

[0016] Such as Figure 1 to Figure 4 As shown, an automatic sample changing device of the present invention includes a hollow spherical shell 10, and the shell 10 is provided with at least two sampling ports (not shown) communicating with the inner cavity of the shell 10, and the sampling port is externally connected to a sampling tube 12, each The sampling tube 12 can be respectively connected to different sampling objects.

[0017] A rotatable hemispherical switch 14 and a driving device 16 for driving the switch 14 to rotate around its own axis are arranged in the inner cavity of the housing 10 . The driving device 16 in a preferred embodiment of the present invention is a stepping motor 18 installed on the inner wall of the housing 10 , and the rotating shaft of the stepping motor 18 is connected to the switch 14 . The switch 14 is provided with a spline groove 20 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com