Water gel gluing process for capacitive touch screen

A capacitive touch screen and lamination technology, applied in the direction of electrical digital data processing, lamination device, lamination auxiliary operation, etc., can solve the problems of low efficiency, no meaning of mass production, no water glue lamination process, etc., and achieve a solution Productivity issues, development-promoting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

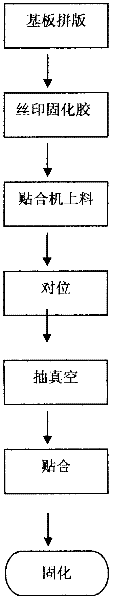

[0016] The water glue bonding process of the capacitive touch screen of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] As shown in Fig. 1, the capacitive touch screen water-glue laminating process of the present invention is: substrate imposition → silk screen curing glue → laminating machine loading → alignment → vacuuming → lamination → curing.

[0018] The substrate imposition is to place the single tempered glass substrates sequentially on the large-format special positioning jig.

[0019] The silk screen curing glue is covered with silk screen curing glue according to the design requirements of the glue application area.

[0020] The loading of the laminating machine is vacuum adsorption of a single piece of conductive glass on the lower loading platform of the laminating machine; vacuum adsorption of the single piece of tempered glass with silk screen printed cured glue on the upper loading platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com