Method and device for demagnetizing steel wire conveying belt without energy consumption

A degaussing method and technology of a degaussing device are applied in the field of transportation machinery to achieve the effects of convenient mobile installation and novel design ideas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

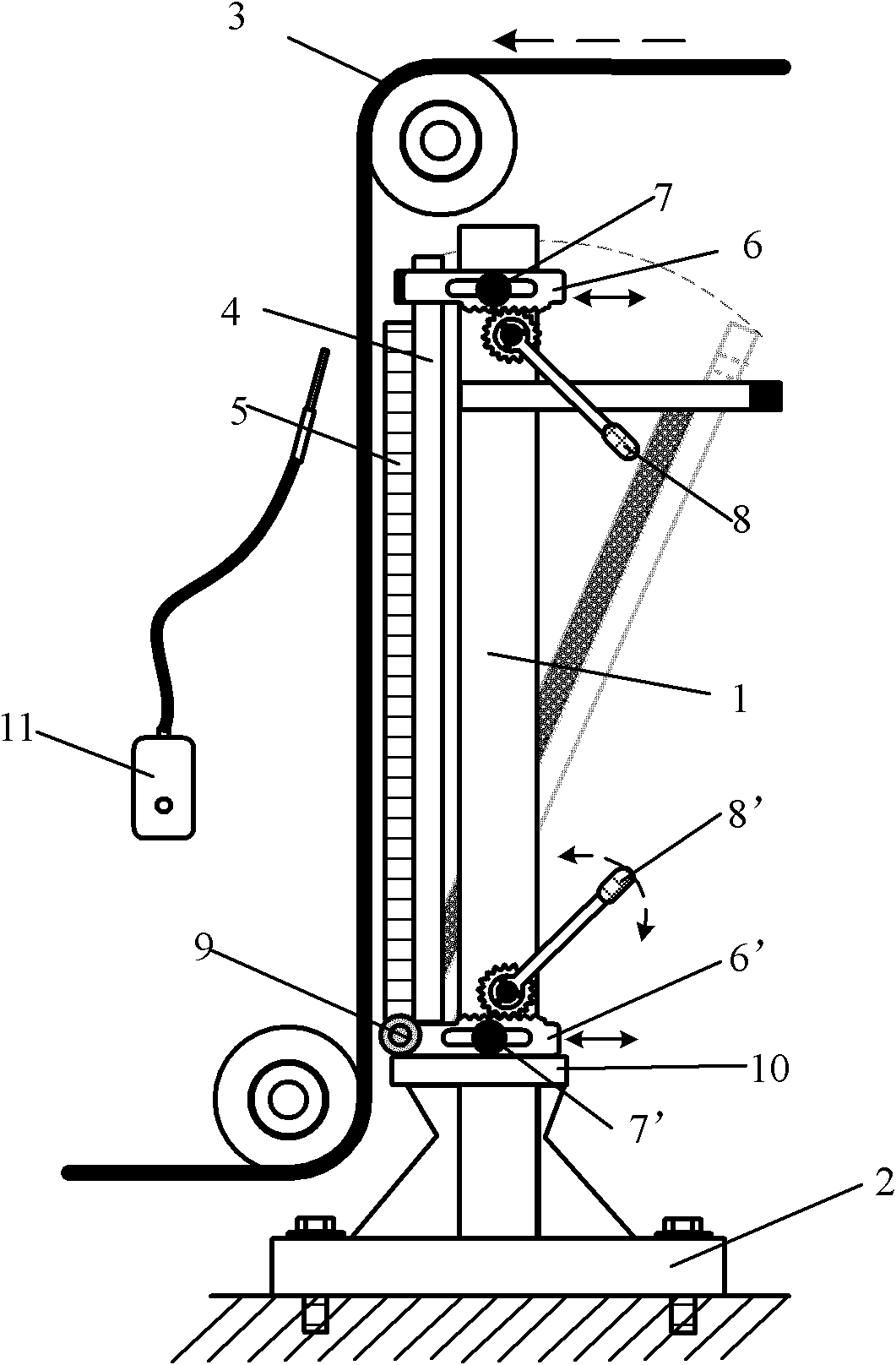

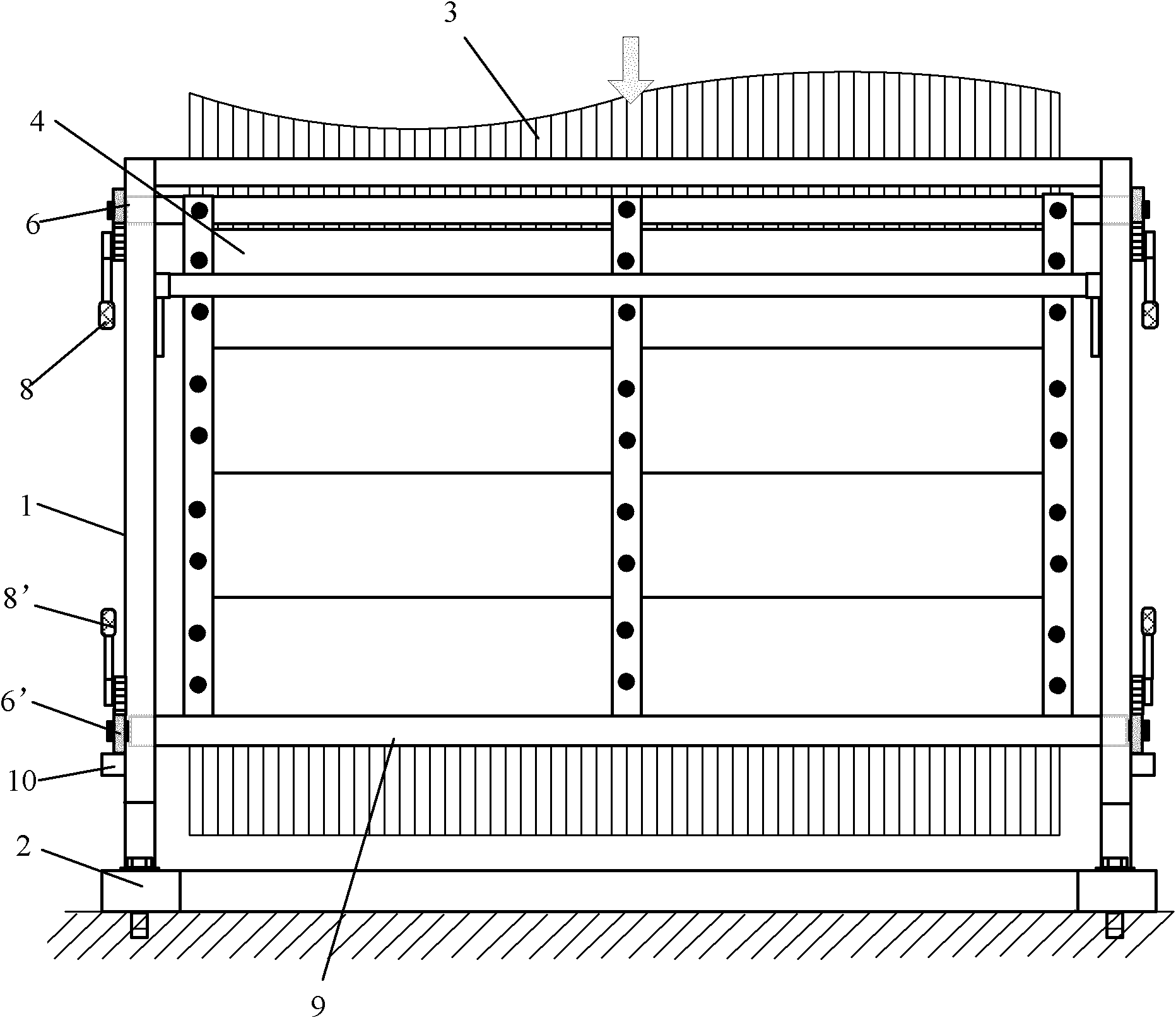

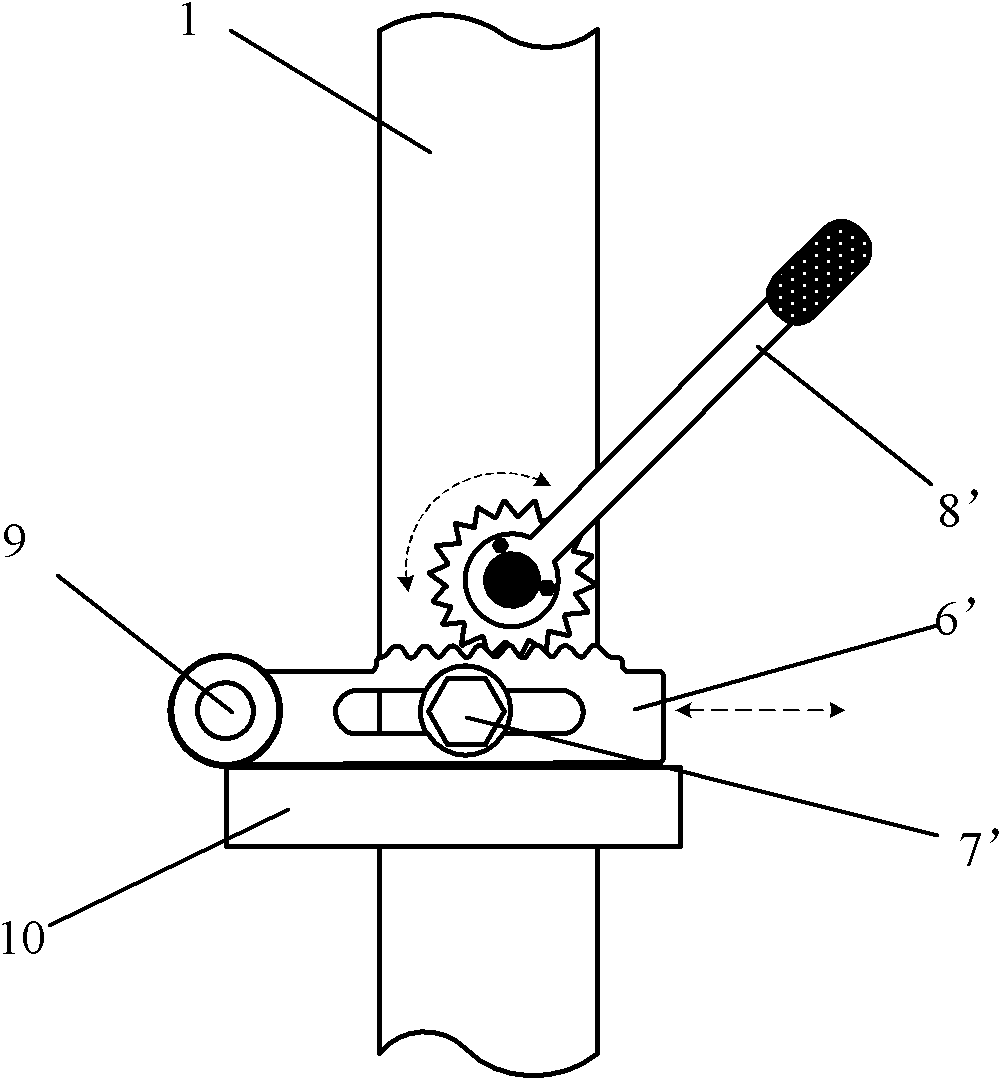

[0026] see Figure 1 ~ Figure 3 , a kind of steel wire conveyer belt non-energy consumption degaussing device of the present invention, it comprises, fixed frame 1, it is installed on the side of steel wire conveyer belt 3 of steel wire conveyer unit unit steel wire conveyer belt 3 through a base 2; 5. Arrange from one end to the other according to the strength of the magnetic field; the four corners of the upper and lower ends of the degaussing plate 4 pass through the adjustment blocks 6, 6' (the upper and lower corners on one side of the degaussing plate are shown in the figure For example) is movably connected with the fixed frame 1 two ends.

[0027] The adjustment blocks 6, 6' at the two ends of the degaussing plate 4 (taking one side of the degaussing plate as an example) provide an adjustment hole, and are connected with the two ends of the fixing frame 1 by bolts 7, 7', and the adjustment blocks 6, 6 A rack is provided on the top; wrenches 8 and 8' with ratchets enga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com