Fixed bracket for connecting section bars in power distribution cabinet

A technology for fixing brackets and power distribution cabinets, which is applied to electrical components, substation/switch layout details, etc. It can solve the problems of weak support strength of low-voltage electrical power distribution cabinets, and achieve the effect of increasing strength, reducing types, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

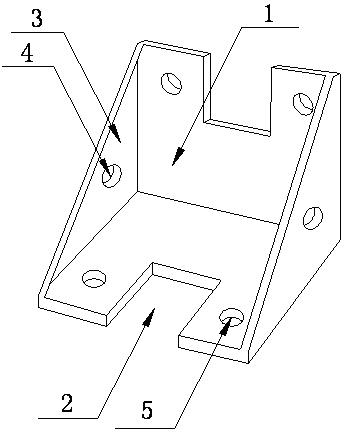

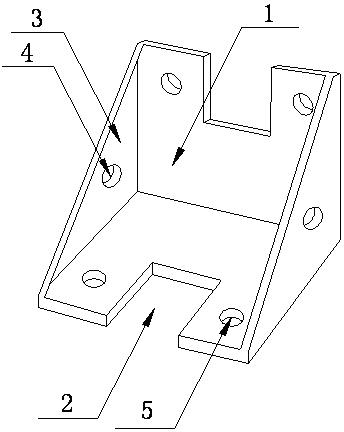

[0012] Such as figure 1 As shown, the present invention includes an L-shaped bracket 1, and two folded edges of the L-shaped bracket 1 respectively open a square groove 2 to form two symmetrical and mutually perpendicular "concave"-shaped structures. The two folded edges of the L-shaped bracket 1 At least two installation holes 5 are also provided on the top; a reinforcing rib 3 for increasing the connection strength of the profile is provided on both sides of the L-shaped bracket 1, and the reinforcing rib 3 is vertically connected with the two folded edges of the L-shaped bracket 1 , At least one assembly hole 4 is provided on the reinforcing rib 3 .

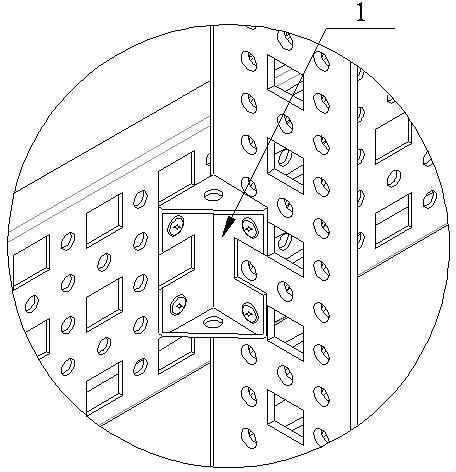

[0013] Such as figure 2 Shown is a schematic diagram of the structure of the present invention installed on the internal profile of the power distribution cabinet. The L-shaped bracket 1 is fixedly connected to the profile with nuts. Due to the addition of two reinforcing ribs 3, the strength of the entire fixed bracket is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com