Detection device and detection method for glass substrate

A technology for a glass substrate and a detection device, applied in the field of detection, can solve problems such as defective finished products, failure to detect glass substrate damage, and influence on the production efficiency of display panels, thereby reducing the probability of defective finished products and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

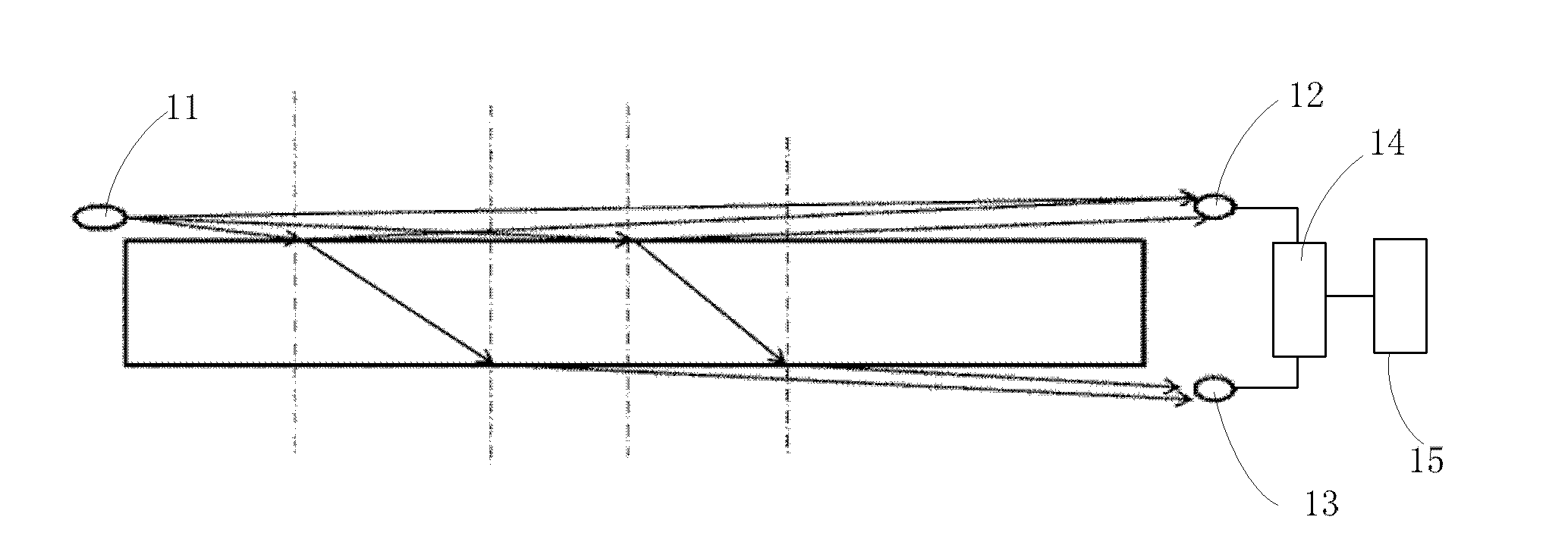

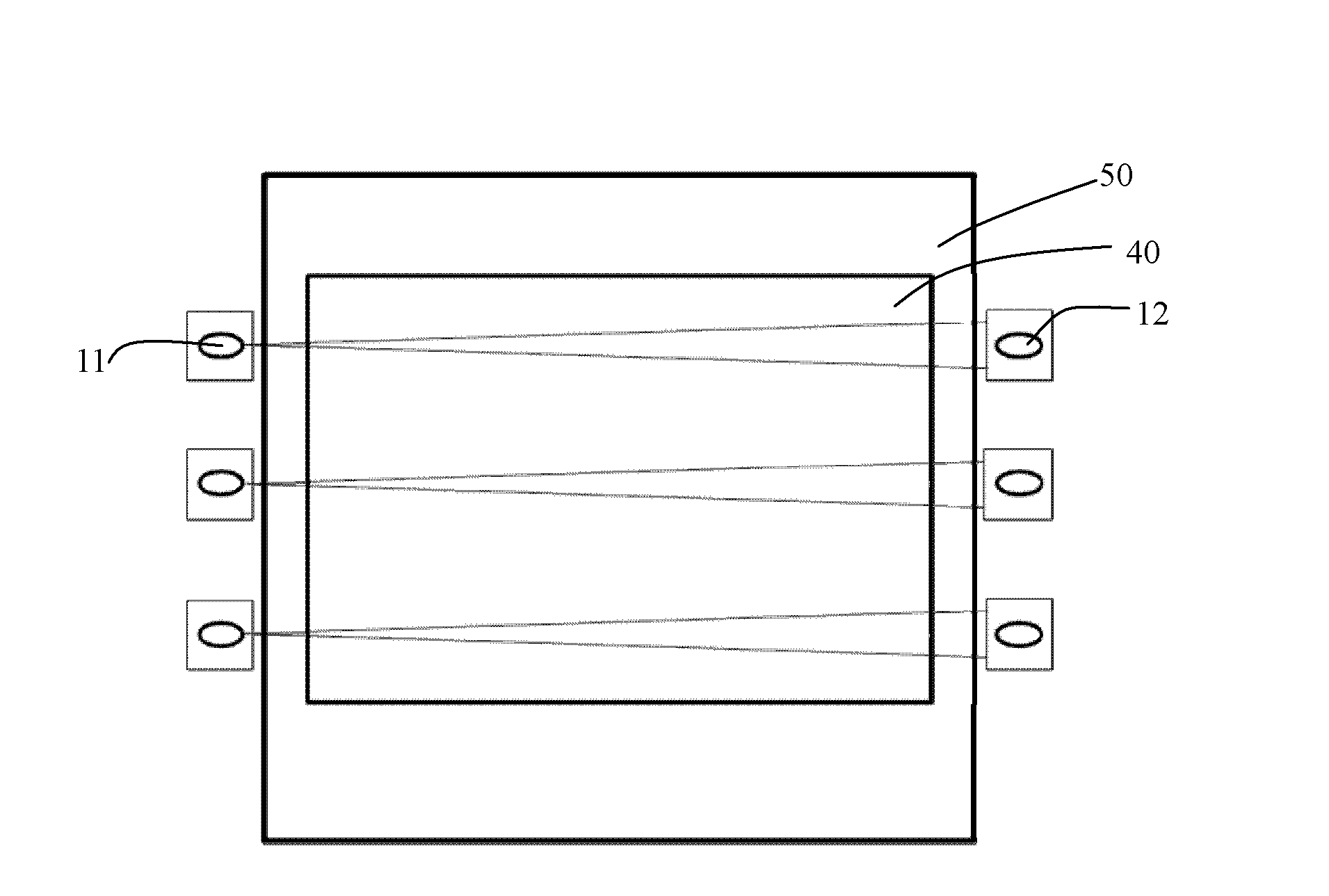

[0013] refer to Figure 1 to Figure 3 , the glass substrate detection device of the embodiment of the present invention is used to detect whether the glass substrate 40 temporarily loaded in the cassette 50 is damaged. The detection device can detect part or all of the glass substrates 40 in the same cassette 50 at one time.

[0014] The cassette 50 is used to carry multiple glass substrates 40 at a time. The cassette 50 includes a plurality of supporting surfaces (not shown) parallel to each other vertically, and each supporting surface is used to carry a glass substrate 40 . After the glass substrates 40 are installed in the cassette 50 , there is a certain distance between adjacent glass substrates 40 . In practical applications, in order to increase the number of glass substrates 40 accommodated in the cassette 50, the distance between adjacent glass substrates 40 is small. Therefore, when the cassette 50 is filled with glass substrates 40, except for the glass substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com