Horizontal convection fan and frame seat thereof

A convection fan, horizontal technology, applied in the direction of non-variable pumps, non-volume pumps, radial flow pumps, etc., can solve the problems of reducing air intake, air turbulence, air volume and air pressure reduction, and achieve reduction Reverse air flow, concentrated air volume, avoiding turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

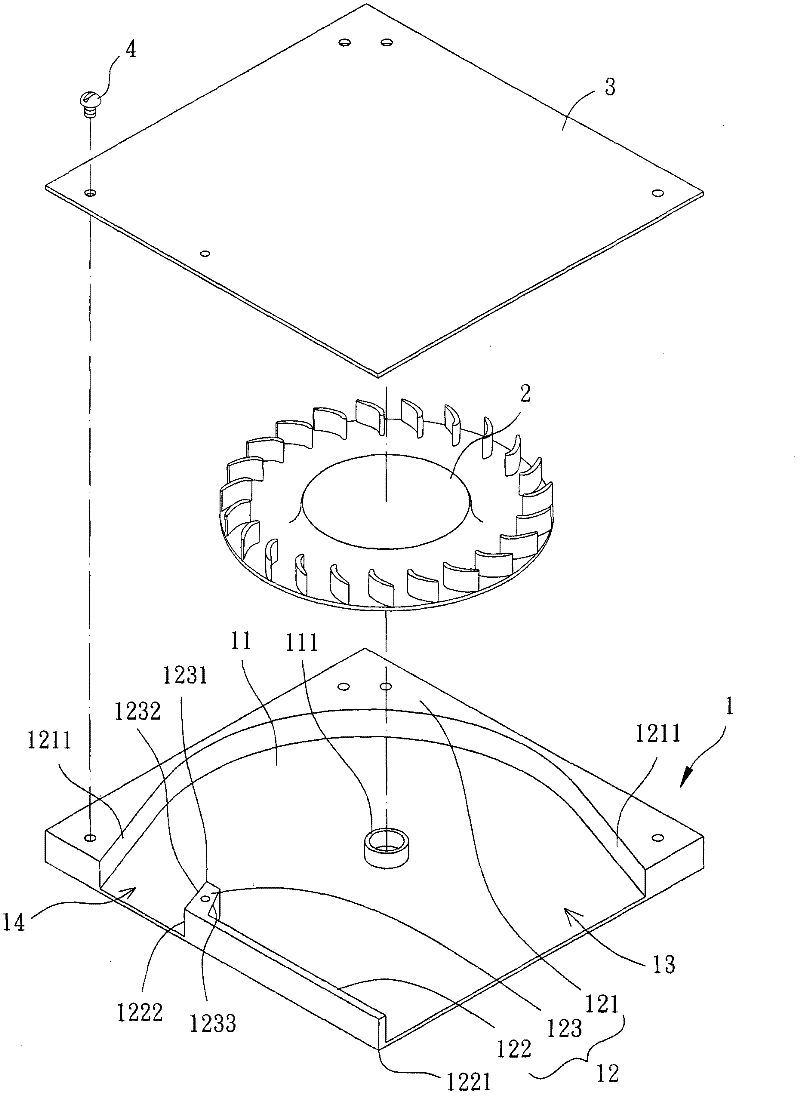

[0054] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, and are described in detail as follows:

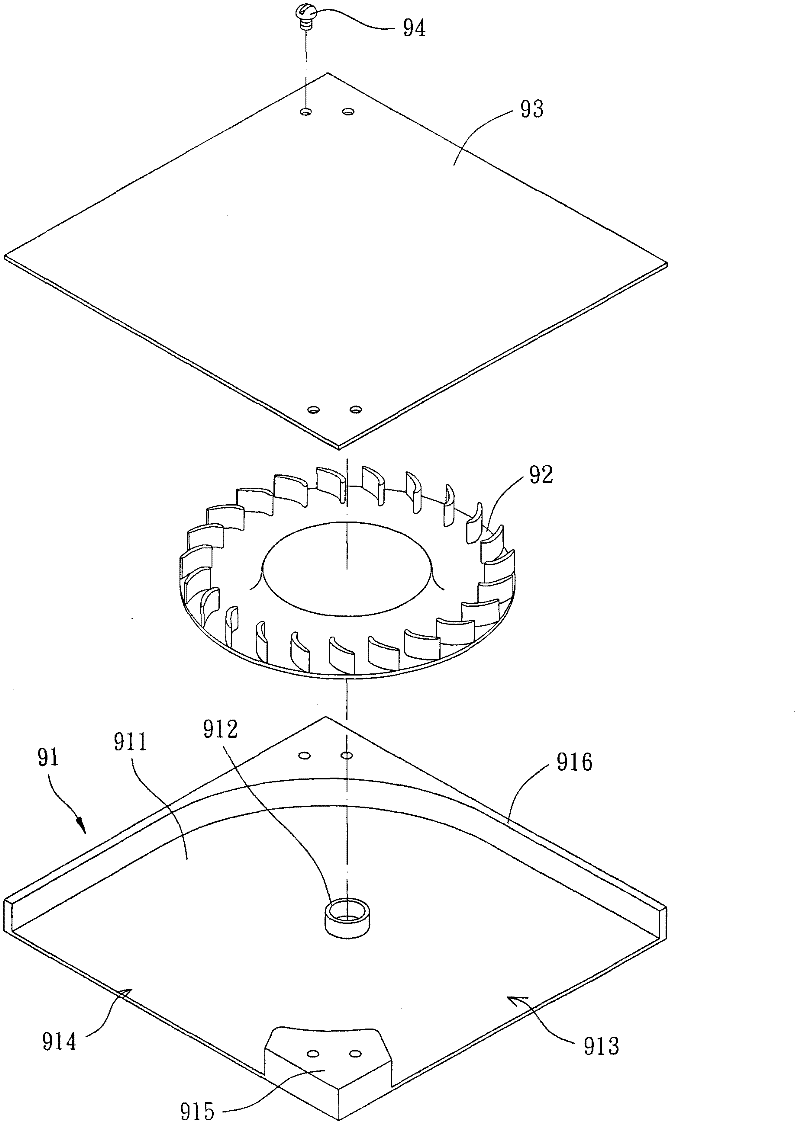

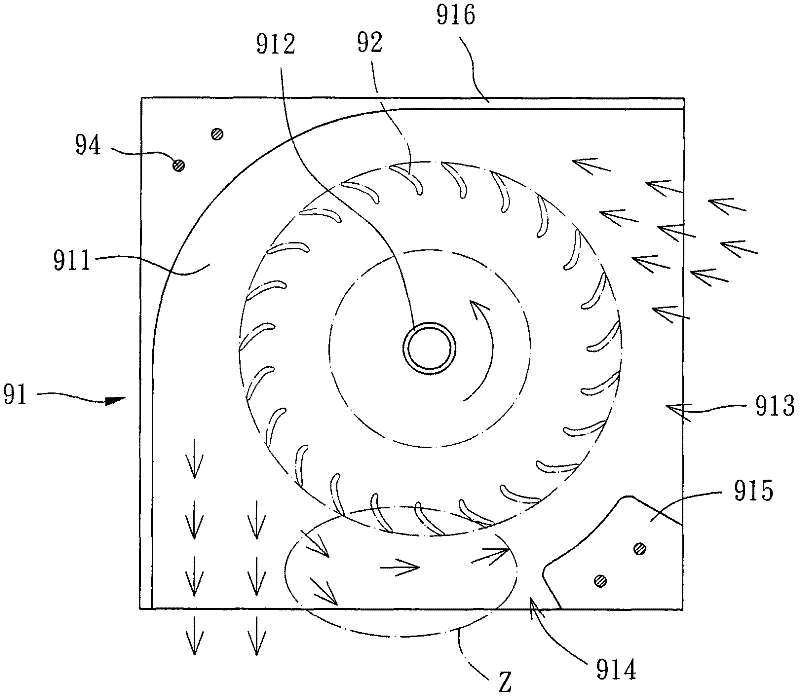

[0055] Please refer to image 3 and Figure 4 As shown, the horizontal convection fan according to the first embodiment of the present invention includes a frame base 1 , a fan wheel 2 and a cover plate 3 . Wherein, the fan wheel 2 and the cover plate 3 are both arranged on the frame base 1, the fan wheel 2 is located between the frame base 1 and the cover plate 3, and can rotate to drive air circulation.

[0056] The frame seat 1 has a bottom plate 11 and a side wall 12 . One surface of the bottom plate 11 is provided with a shaft seat 111, the side wall 12 is formed on the surface of the bottom plate 11 provided with the shaft seat 111, and is located at the outer periphery of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com