Jet nozzle cleaning mechanism of ink-jet printing device

An inkjet printing device and nozzle technology, applied in printing and other directions, can solve the problems of ink waste, increase the cost of the inkjet printing device, increase the volume of the inkjet printing device, etc., and achieve the effect of saving ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

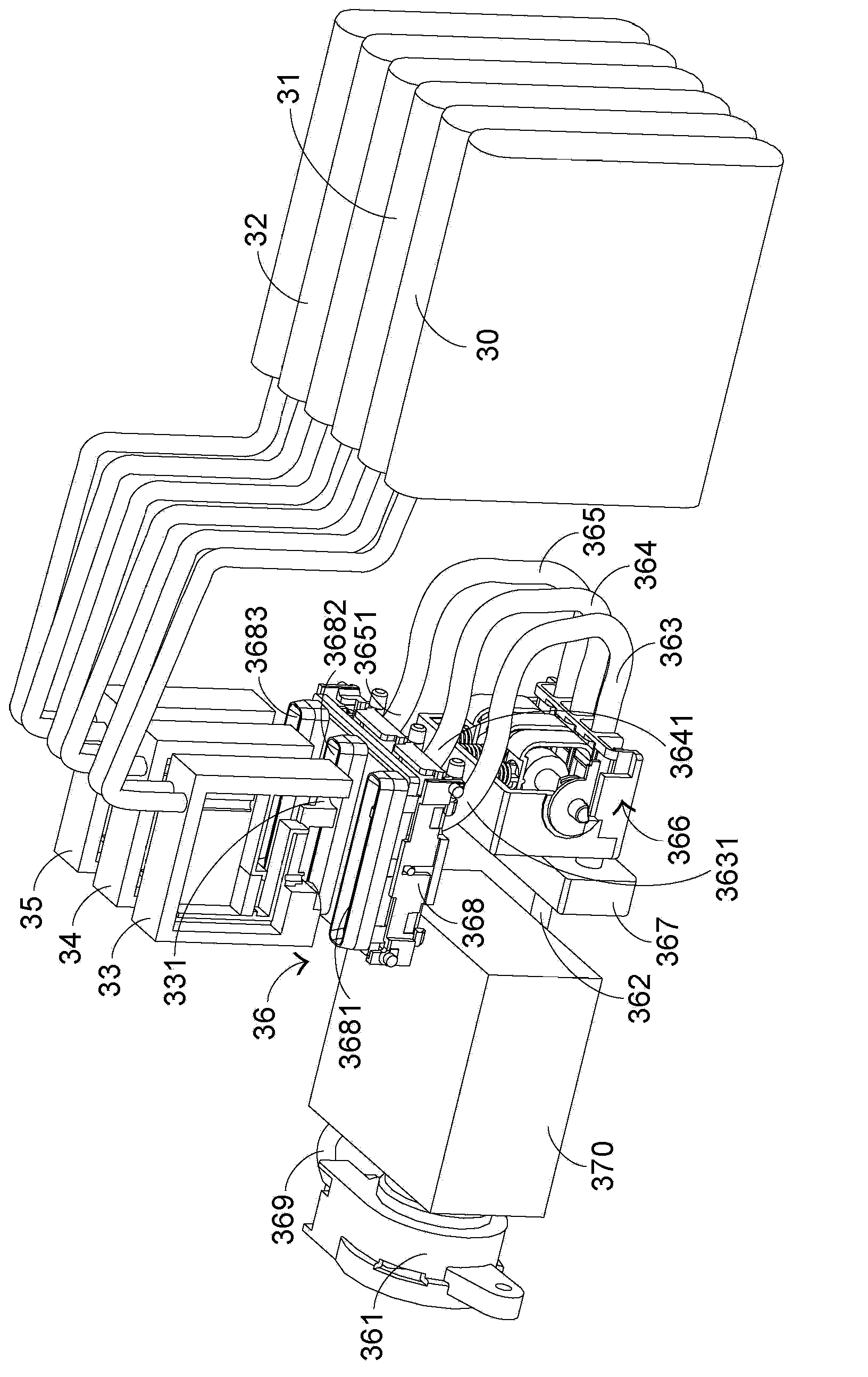

[0096] The invention provides a nozzle cleaning mechanism of an inkjet printing device. Please also see image 3 as well as Figure 4 , image 3It is a schematic diagram of the appearance structure of the nozzle cleaning mechanism and the local structure of the inkjet printing device in the first preferred embodiment of the inkjet printing device of the present invention, and Figure 4 It is a partial structure diagram of the nozzle cleaning mechanism of the inkjet printing device in the first preferred embodiment of the present invention. image 3 Only a first ink cartridge 30, a second ink cartridge 31, a third ink cartridge 32, a first print head 33, a second print head 34, a third print head 35 and a nozzle cleaning of the inkjet printing device are shown Mechanism 36 does not show other structures of the inkjet printing device, its first ink cartridge 30 is used to store a first ink (not shown in the figure), and the second ink cartridge 31 is adjacent to the first ink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com