Method and system for oil life monitoring

A technology of engine oil and engine, which is applied in the directions of lubricating indicator devices and lubricating parts, and can solve problems such as jamming, engine component wear, loss of sufficient lubricating engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

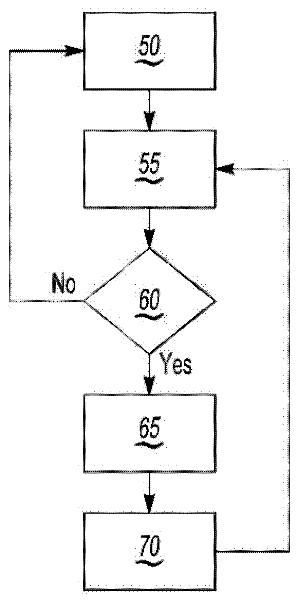

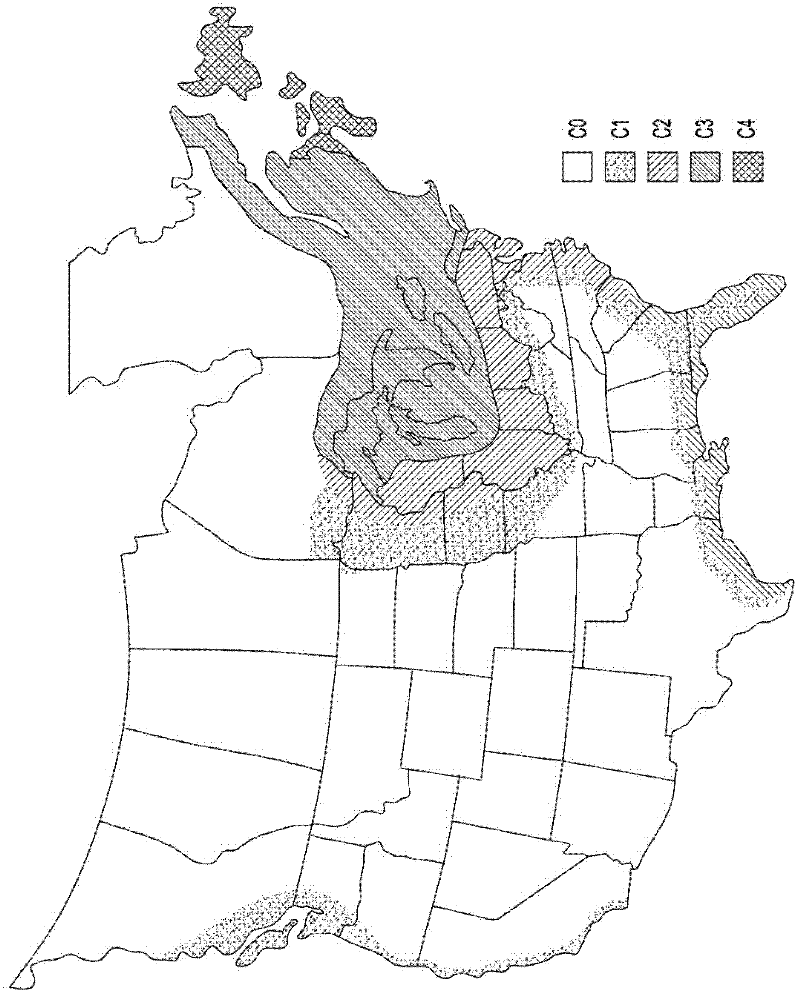

[0020] Referring to the drawings, wherein like reference numerals indicate like parts throughout the several views, Figure 1-3 The elements in are not necessarily to size or scale. Accordingly, the specific representations, dimensions and applications provided in the drawings presented herein should not be considered limiting.

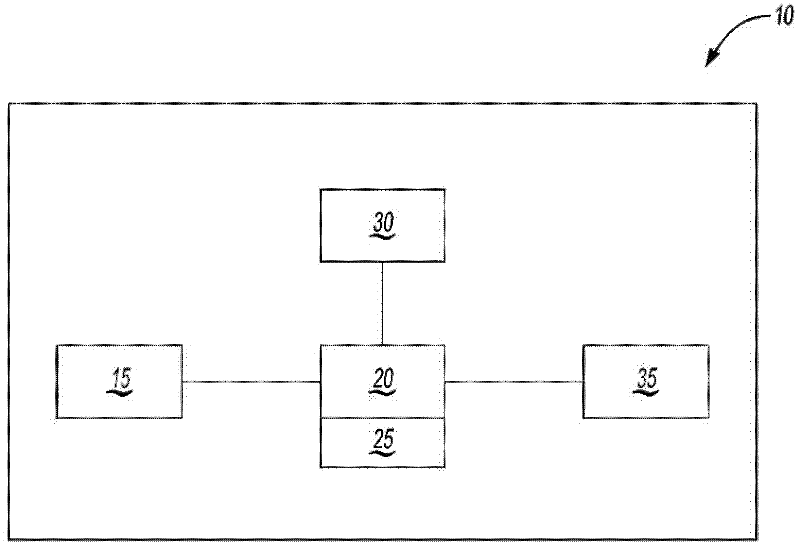

[0021] figure 1 is a schematic diagram of the system indicated generally at 10 . System 10 includes controller 20 and engine 15 . The controller 20 includes an algorithm 25 , wherein the algorithm 25 may be configured to generate an oil change index and a maximum oil change limit for the engine 15 . Controller 20 may be defined by one or more engine control modules (not shown) (also referred to as engine control units) and oil life monitor modules (not shown) (also referred to as oil life monitors or lubrication control modules) .

[0022] Controller 20 may further be configured to be in operative communication with, or defined by, one or more of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com