Pouring formwork and pouring method for large biogas tank body

A biogas digester and formwork technology, which is applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connection, construction, etc. The effect of rapid modeling and demoulding, speeding up construction and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

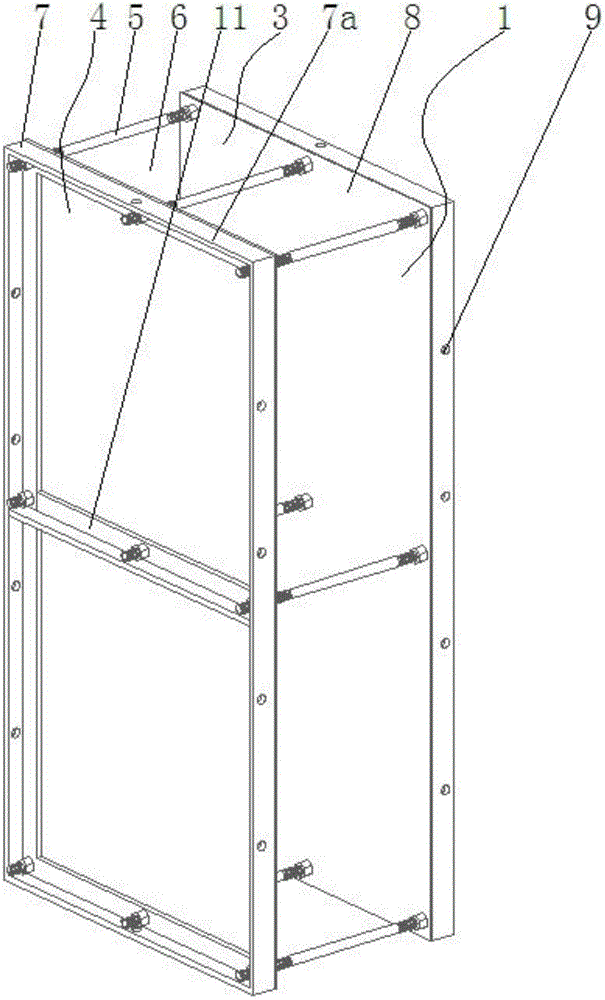

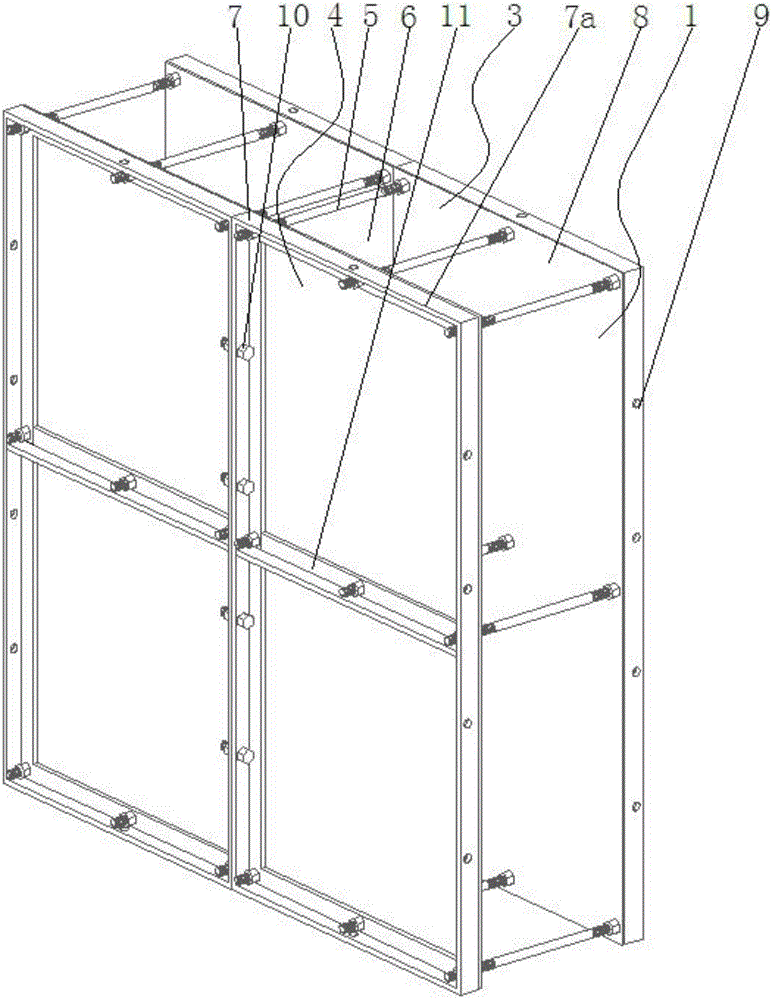

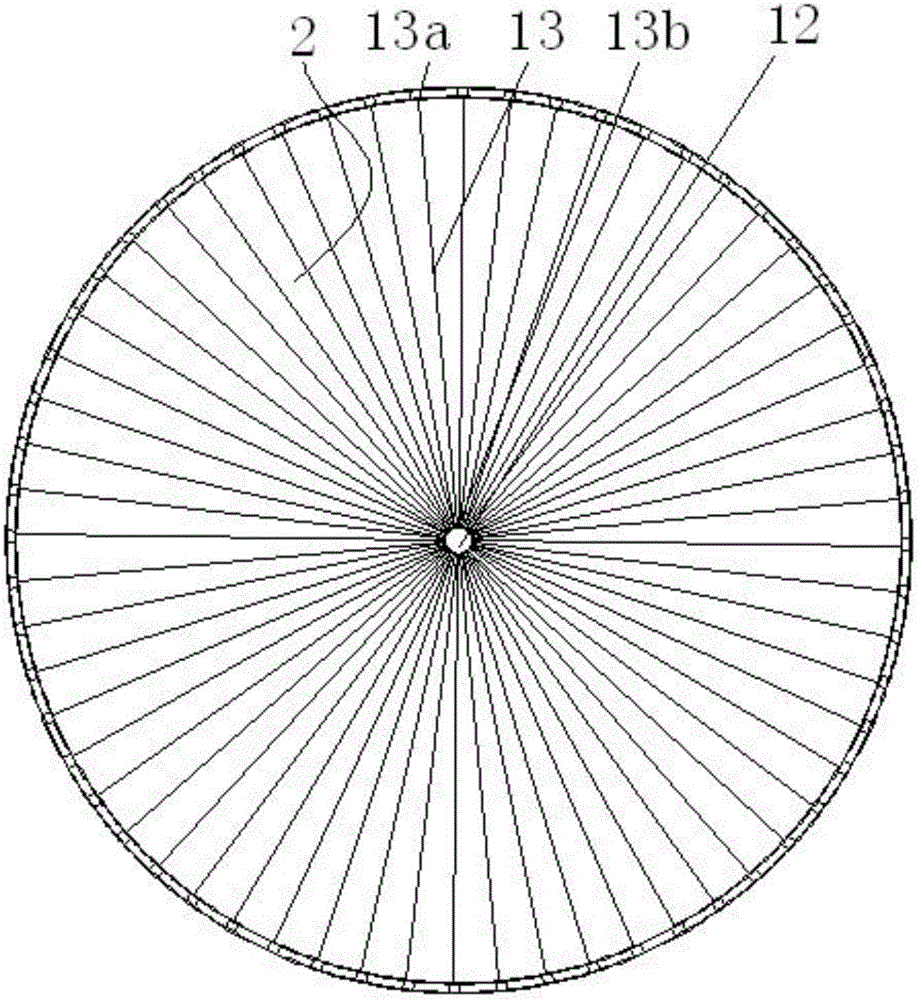

[0021] Such as figure 1 , 2 Or as shown in 3, a pouring formwork 1 for a large biogas tank body, the pouring formwork 1 is connected to each other to form a pouring ring 2, the pouring formwork 1 includes an inner formwork 3 and an outer formwork 4, and the inner formwork 3 and the outer formwork 4 are connected by bolts 5 connection, a molding cavity 6 is formed between the inner formwork 3 and the outer formwork 4, both the inner formwork 3 and the outer formwork 4 are a "door frame"-shaped metal skeleton 7 composed of angle steel, the bending surface 7a of the angle steel faces outward, and the steel plate 8 is welded On the inner side of the metal frame 7, the inner formwork 3 and the outer formwork 4 are provided with keyholes 9 on the left and right sides, and the pouring formwork 1 of several large biogas digesters is connected and assembled into a circular shape through the keyholes 9 and bolts 10 corresponding to the left and right sides. Digester body pouring circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com