Sump dredging system and mode

A technology for water collection wells and dredging devices, which is applied in waterway systems, water supply devices, cleaning sewer pipes, etc., can solve the problems of not being able to select submersible sewage pumps, not being able to select sewage pumps, and high drainage head, and achieve a wide range of applications. Avoid secondary pollution, less equipment and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

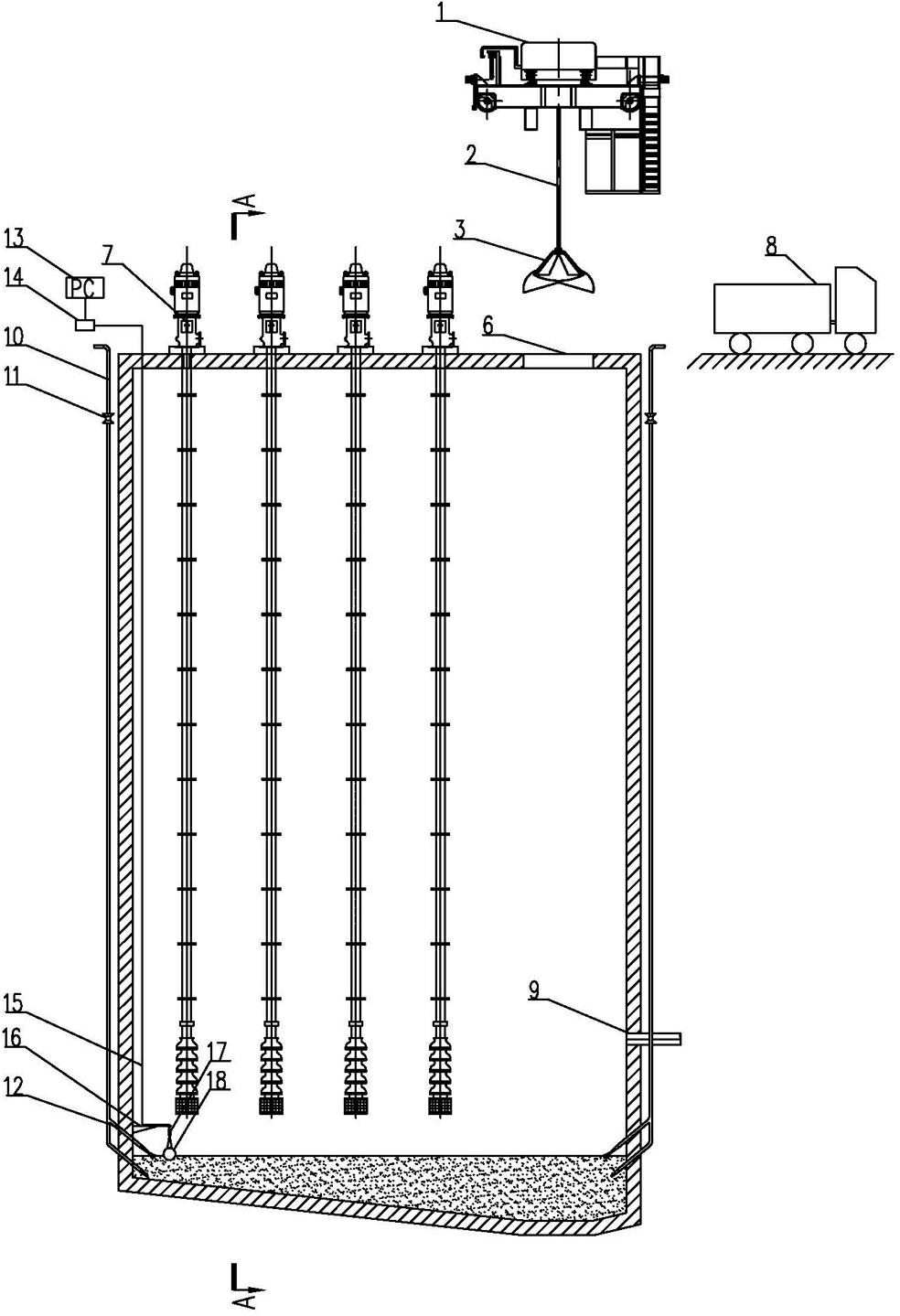

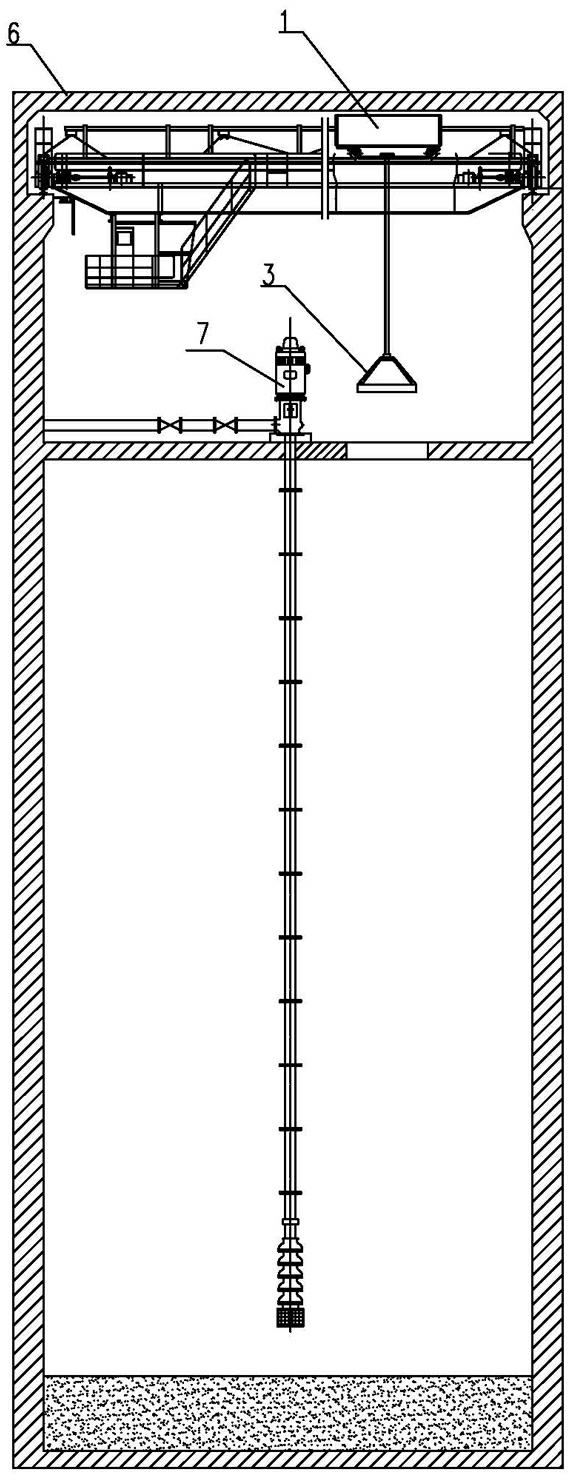

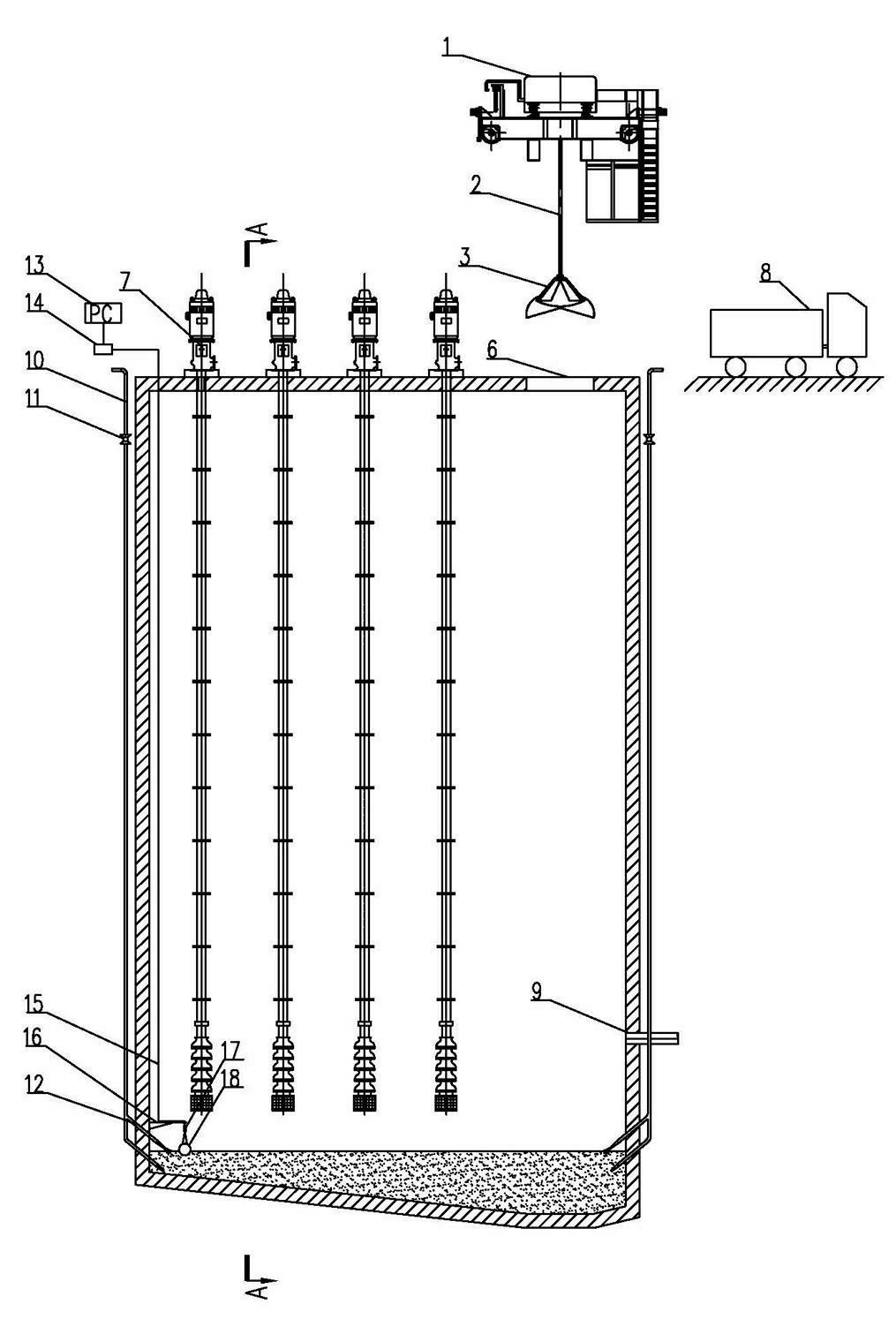

[0023] Such as figure 1 , figure 2 As shown, the present embodiment is a new type of water collection well dredging system, in which drainage facilities 7 are installed in the water collection well 6, and the bottom plate of the water collection well is made at an appropriate angle of inclination (that is, one area of the bottom plate of the water collection well is lower, and the rest of the bottom plate The area is inclined at a certain angle with this area, which is convenient to concentrate the sediment in the water collection well in this area), and the sandy water flow collection pipe 9 is buried near the lower area of the bottom of the water collection well. Install a grab-type dredging device above the water collection well and at the lowest point corresponding to the bottom plate. In this embodiment, a sediment density and sediment height measurement system and a sediment collection high-pressure flushing system are also set at the bottom of the water collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com