Marine fender

A fender and marine technology, which is applied in the direction of hull, ship construction, ship cleaning device, etc., can solve the problems of wear and high friction coefficient, and achieve the effect of small degradation of anti-compression load performance, small compression surface pressure, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

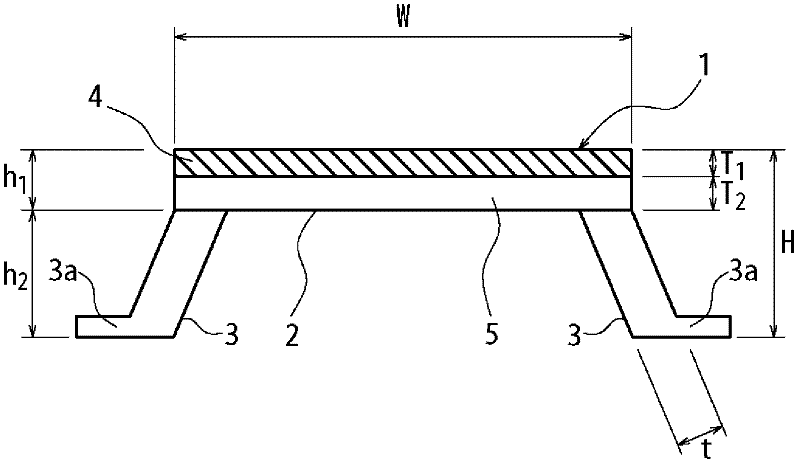

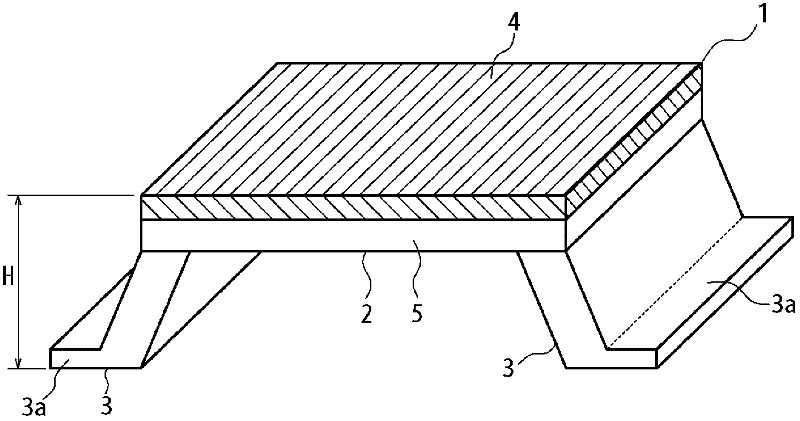

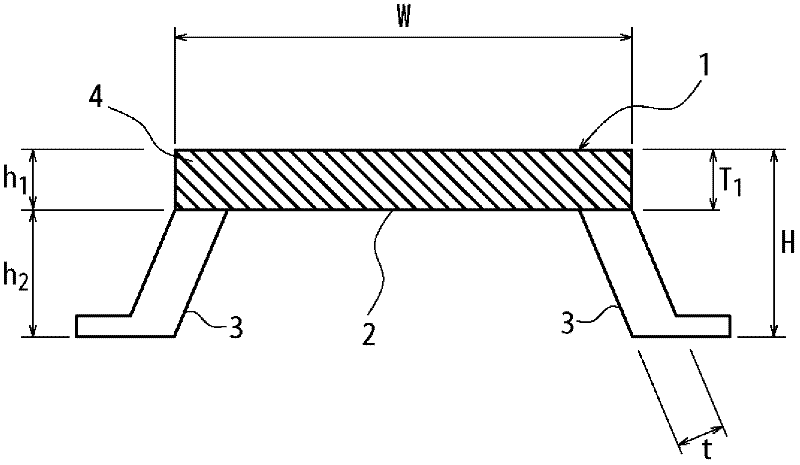

[0062] The present invention will be described in detail with reference to the accompanying drawings. exist figure 1 with figure 2 A marine fender 1 shown in includes a vibration receiving portion 2 that receives vibration when a ship is moored, and a pair of leg portions 3 attached to the lower surface of the vibration receiving portion 2 . At this time, the leg portion 3 is made of rubber, and a flange 3 a for fixing the fender 1 to a quay wall or the like is provided on the leg portion 3 . figure 1 with figure 2 The vibration receiving part 2 in includes: a vibration receiving plate 4 made of resin at the surface in contact with the ship (that is, the outermost surface); and a vibration receiving plate 4 made of rubber and vibrating in the height direction (or The vibration receiving plate 5 is arranged on the lower side of the vibration receiving resin plate 4 in the thickness direction of the receiving plate). In addition, it is sufficient that the vibration recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com