Centering clamping device of hydraulic forging machine

A clamping device and hydraulic press technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve the problems of long alignment time, large manipulator structure size, and increased labor intensity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

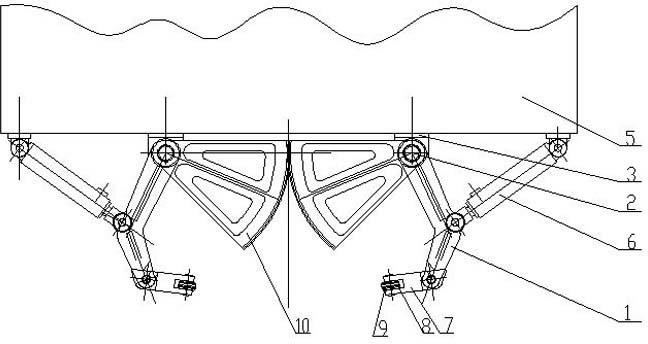

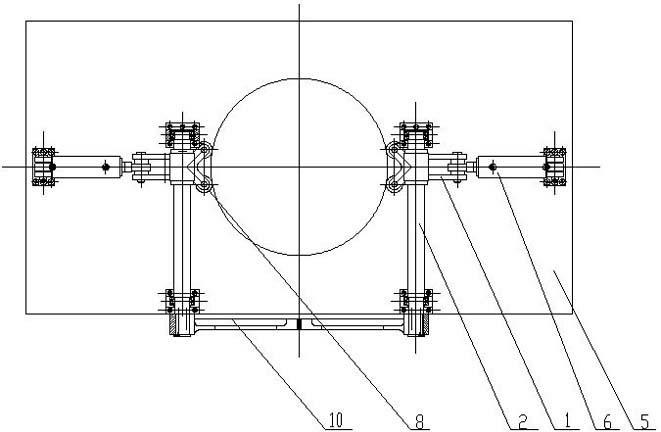

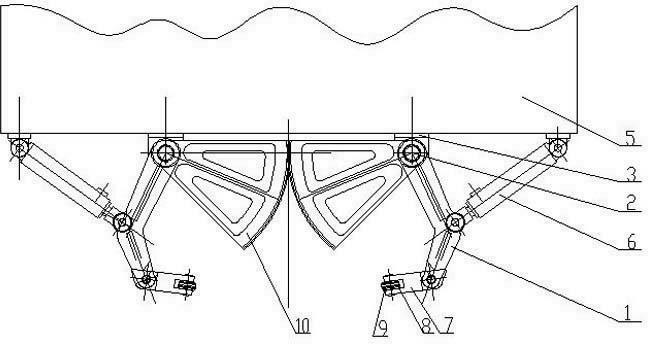

[0011] figure 1 and figure 2 The centering and clamping device of a forging hydraulic press shown includes a symmetrically arranged mechanical arm 1, the upper end of which is sleeved on a spline shaft 2, and the spline shaft 2 is arranged on a fixed support 3, and the fixed support 3 Fixedly connected on the slide block 5 of the hydraulic press. An oil cylinder 6 is arranged between the middle part of the mechanical arm 1 and the slide block 5 of the hydraulic press. The lower end of the mechanical arm 1 is provided with a mechanical claw 7, and the clamping wheel 8 is arranged on the mechanical claw 7.

[0012] By arranging the mechanical claw 7 and the clamping wheel 8 on the mechanical arm 1, the flexibility and flexibility of the device are enhanced. In order to increase the clamping force, a friction groove 9 is provided on the clamping wheel 8 . In order to increase the synchronization of the device, the ends of the two symmetrically arranged spline shafts 2 are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com