Track sucker type wall surface cleaning robot

A cleaning robot and sucker-type technology, which is applied to cleaning machinery, cleaning equipment, machine parts, etc., can solve the problem of non-negligible power consumption, and achieve the effects of improving energy efficiency, strong reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A. The structure and assembly of the track:

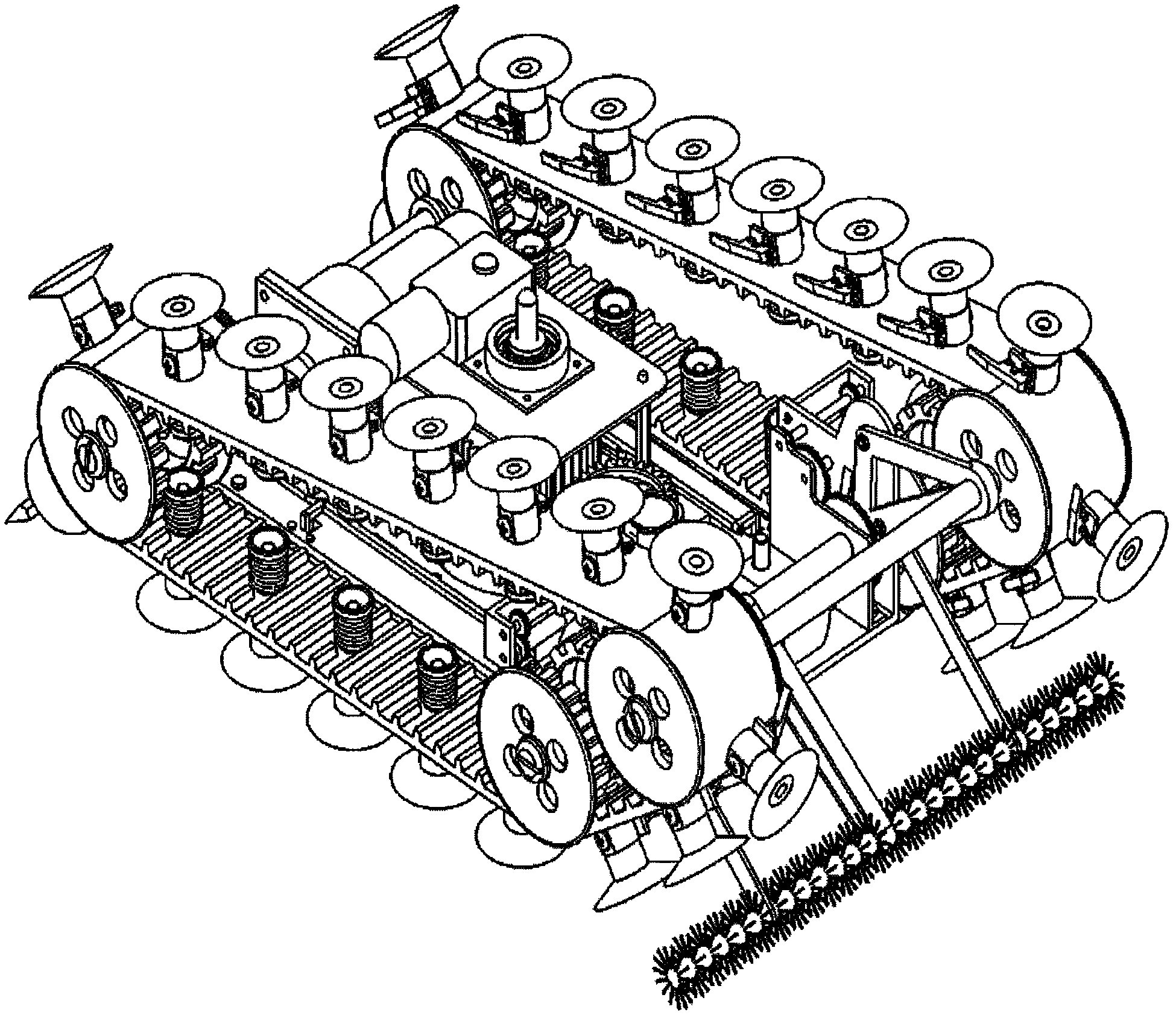

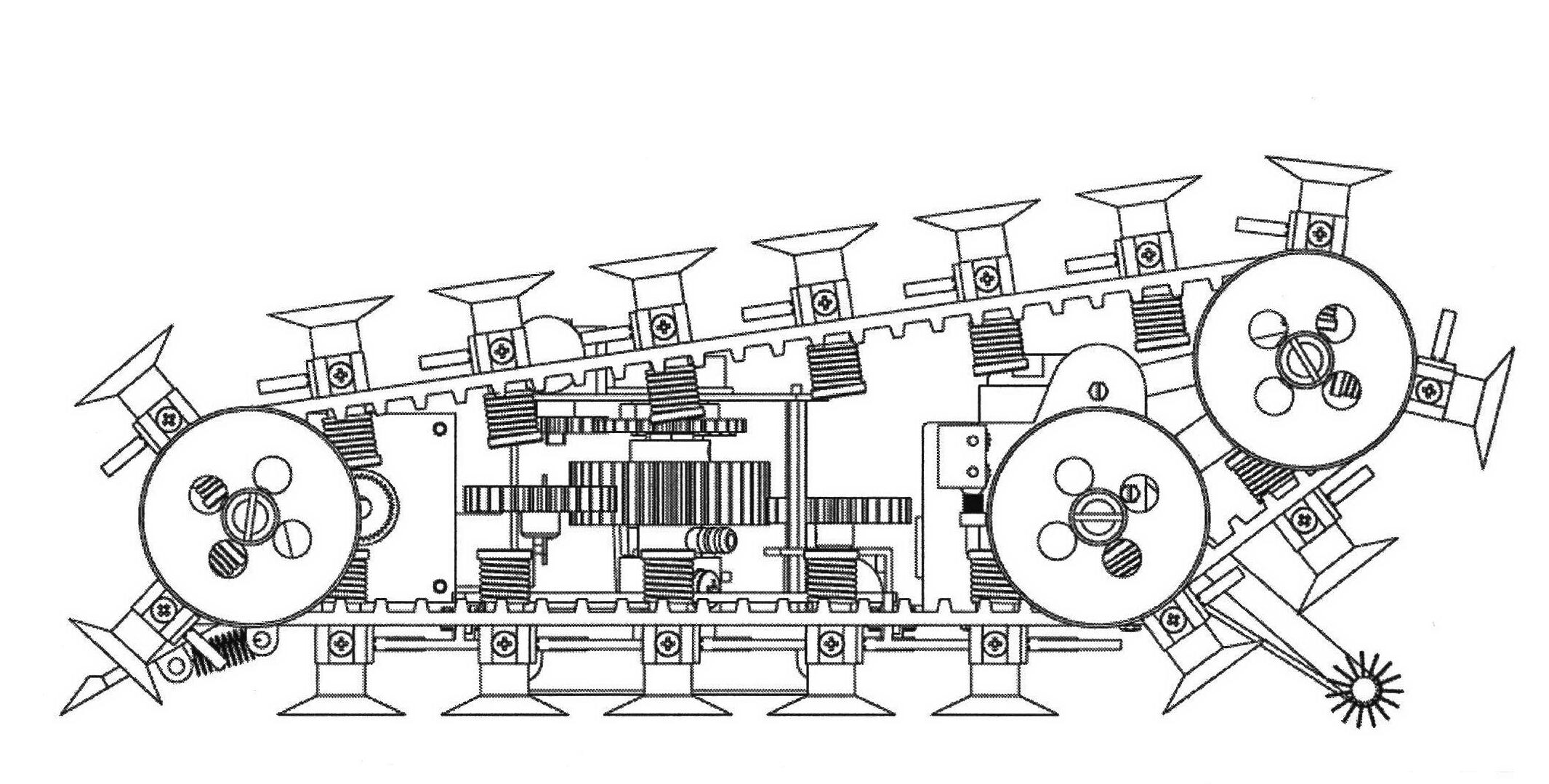

[0024] as attached Image 6 Shown, crawler track is made up of synchronous belt (25), synchronous wheel (24), driving wheel (26), suction cup assembly (23). In order to ensure the transmission ratio, by calculating the theoretical value of the distance between each suction cup, holes are drilled on the synchronous belt, and the suction cup and the synchronous belt are connected through the pressure belt spring.

[0025] B. Structure and assembly of steering mechanism:

[0026] as attached Figure 7 And attached Figure 8 shown. The steering mechanism mainly consists of steering driving gear (20), steering driven gear (17), lifting driving gear (18), lifting driven gear (16), ball screw (19), central sucker (21), bearing (15), Circlip (22) etc. are formed. The central sucker and the lead screw are at the coaxial position, and they are fixedly connected; directly above the sucker, the steering driven gear (17) is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com