Arc-extinguishing load switch and switch equipment

A load switch and arc extinguishing technology, applied in electric switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve problems such as limited arc extinguishing capacity, arc extinguishing failure, complex structure, etc., to reduce consumption and improve extinguishing Arc ability, size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

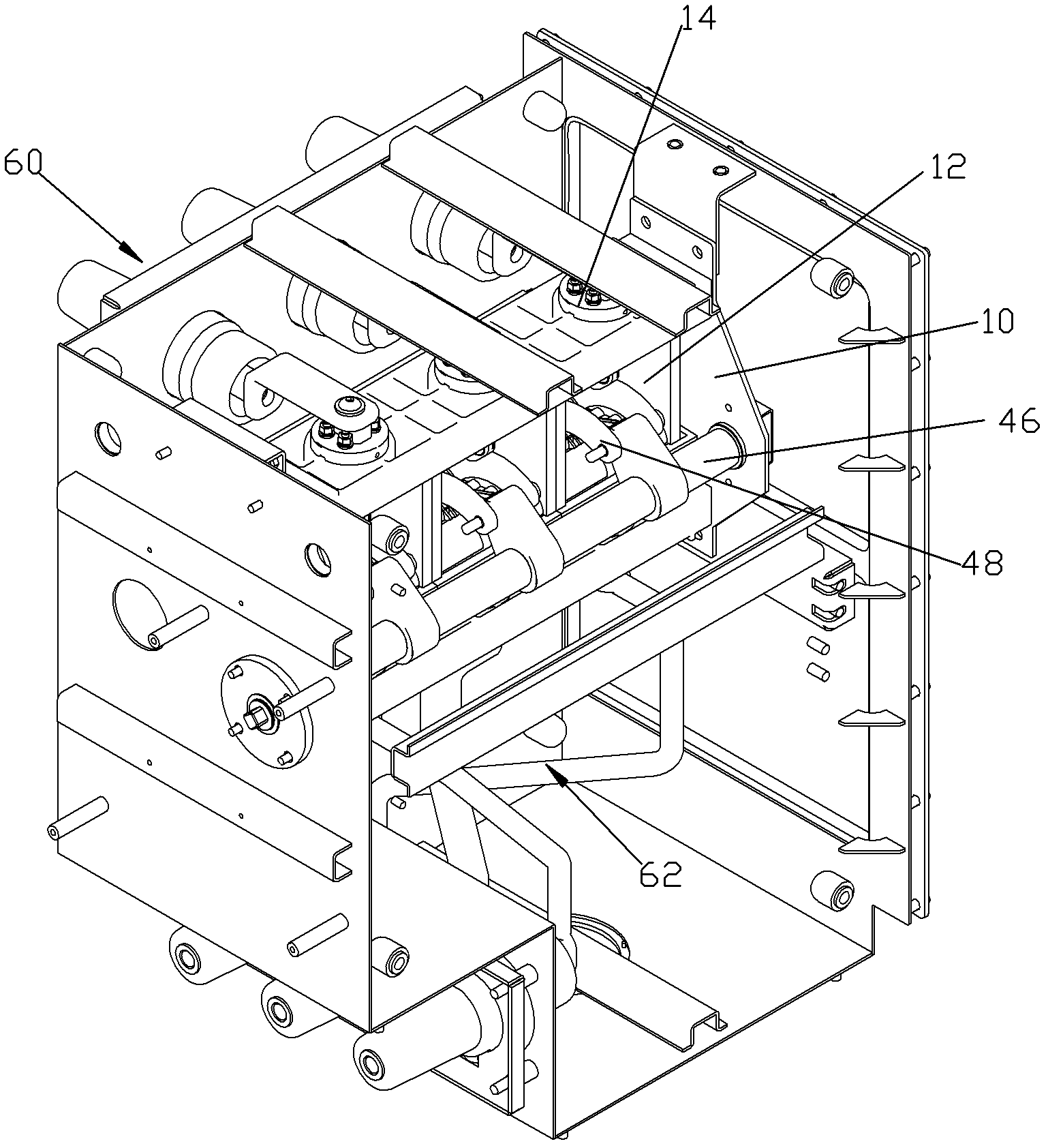

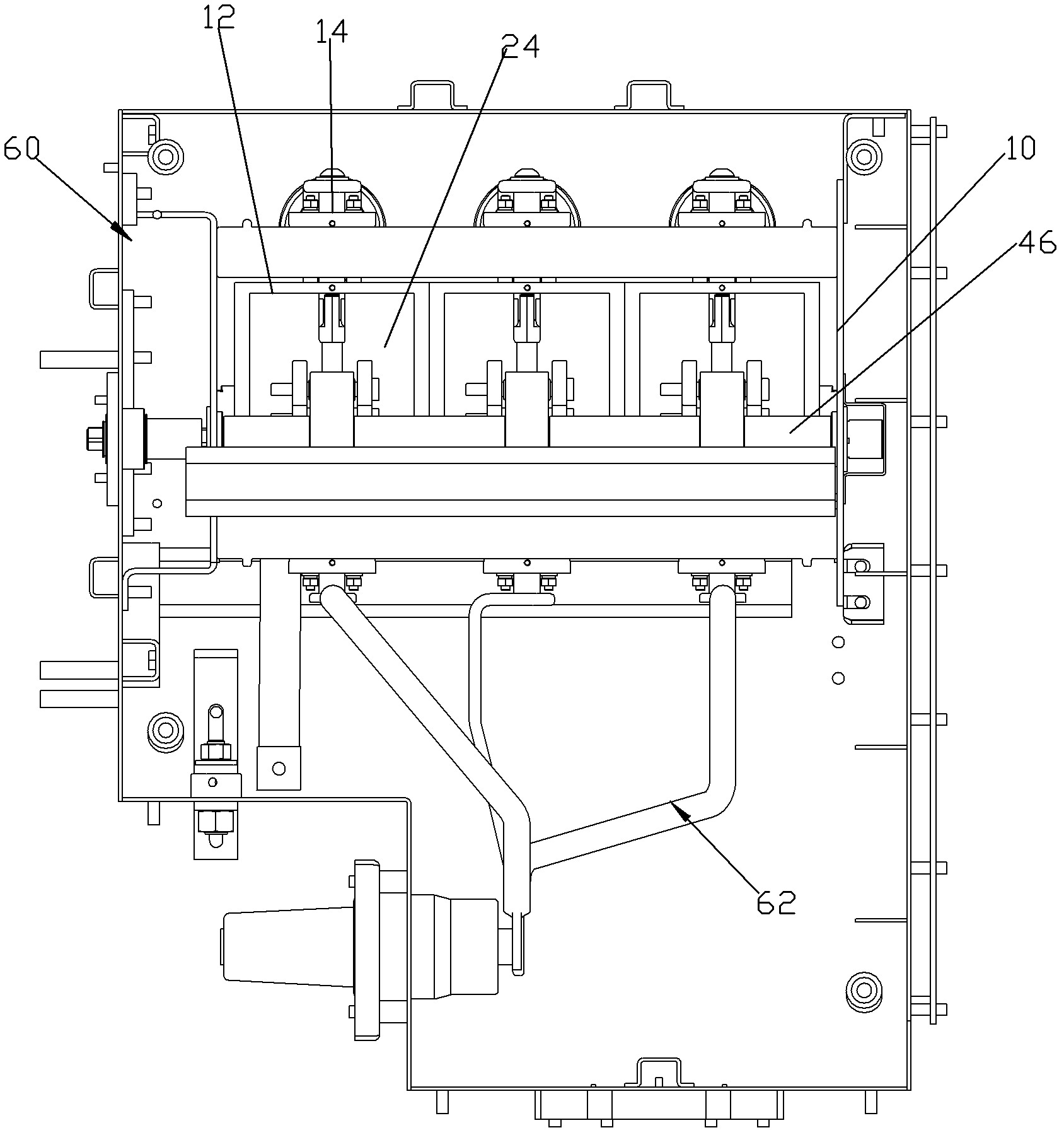

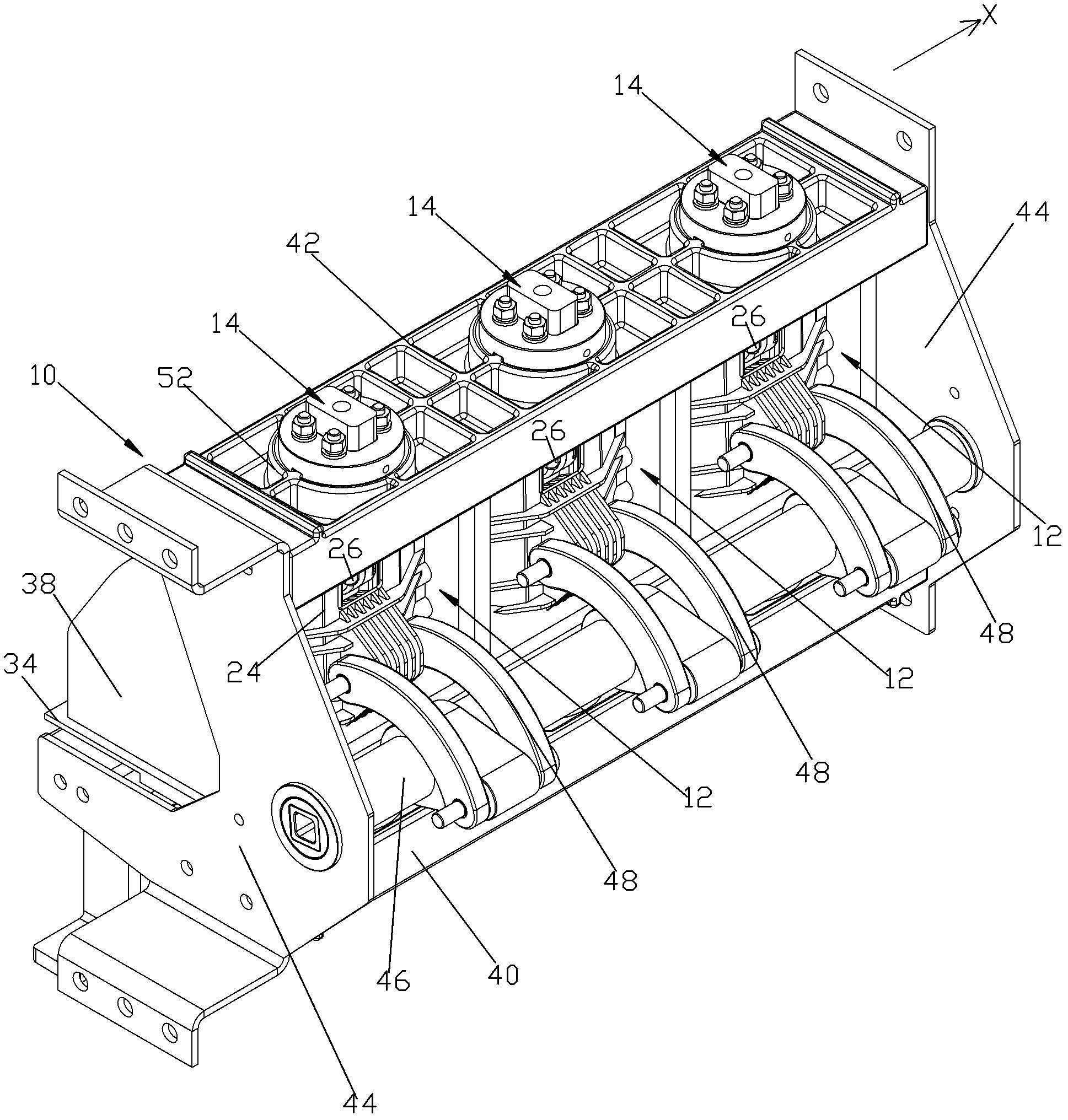

[0033] Please check Figure 1 to Figure 12 , arc extinguishing load switchgear, which includes a metal enclosed frame 60, an arc extinguishing load switch and a main bus 62; said metal enclosed frame 60 is filled with arc extinguishing gas, such as SF 6 ; The arc extinguishing load switch is installed in the metal enclosed frame 60 . The arc extinguishing load switch includes a base 10 fixed in a metal closed frame 60 and a three-phase switch assembly.

[0034] The base 10 includes a lower base 40 , an upper base 42 and two side frames 44 fixedly connected to the upper base 42 and the lower base 40 .

[0035] The three-phase switch assemblies are mounted on the base 10 and arranged side by side along the direction X. Each phase switch assembly includes an upper static contact assembly 14 , a lower static contact assembly 16 , a moving contact 18 and a grounding assembly 20 . The upper static contact assembly 14 includes an upper static contact 50 and an upper static contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com