Floating type connector

A connector, floating type technology, applied in the direction of connection, parts of the connection device, contact parts, etc., can solve problems such as difficult to align the position, and achieve the effect of reducing manufacturing cost, simple shape, and preventing plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

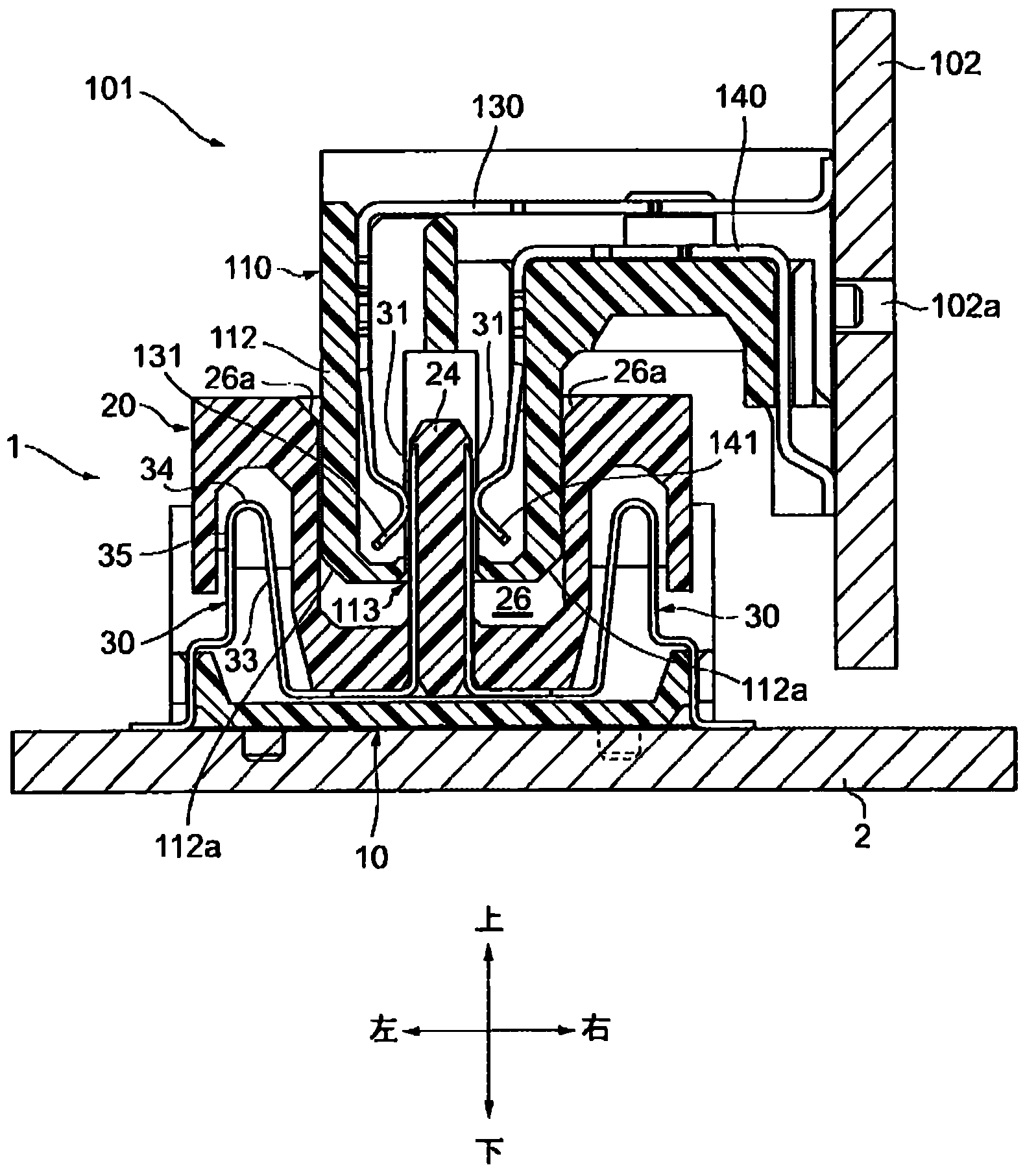

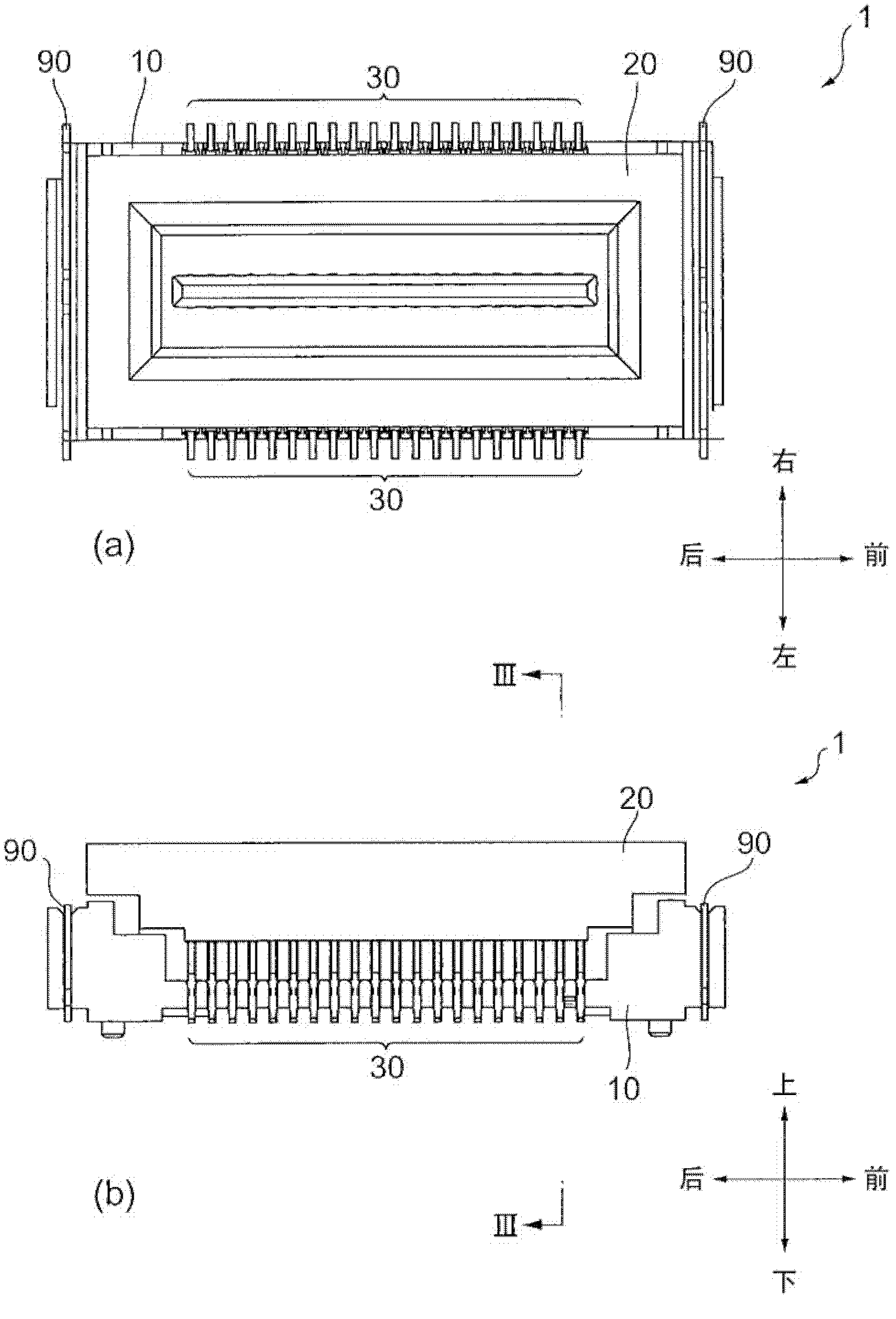

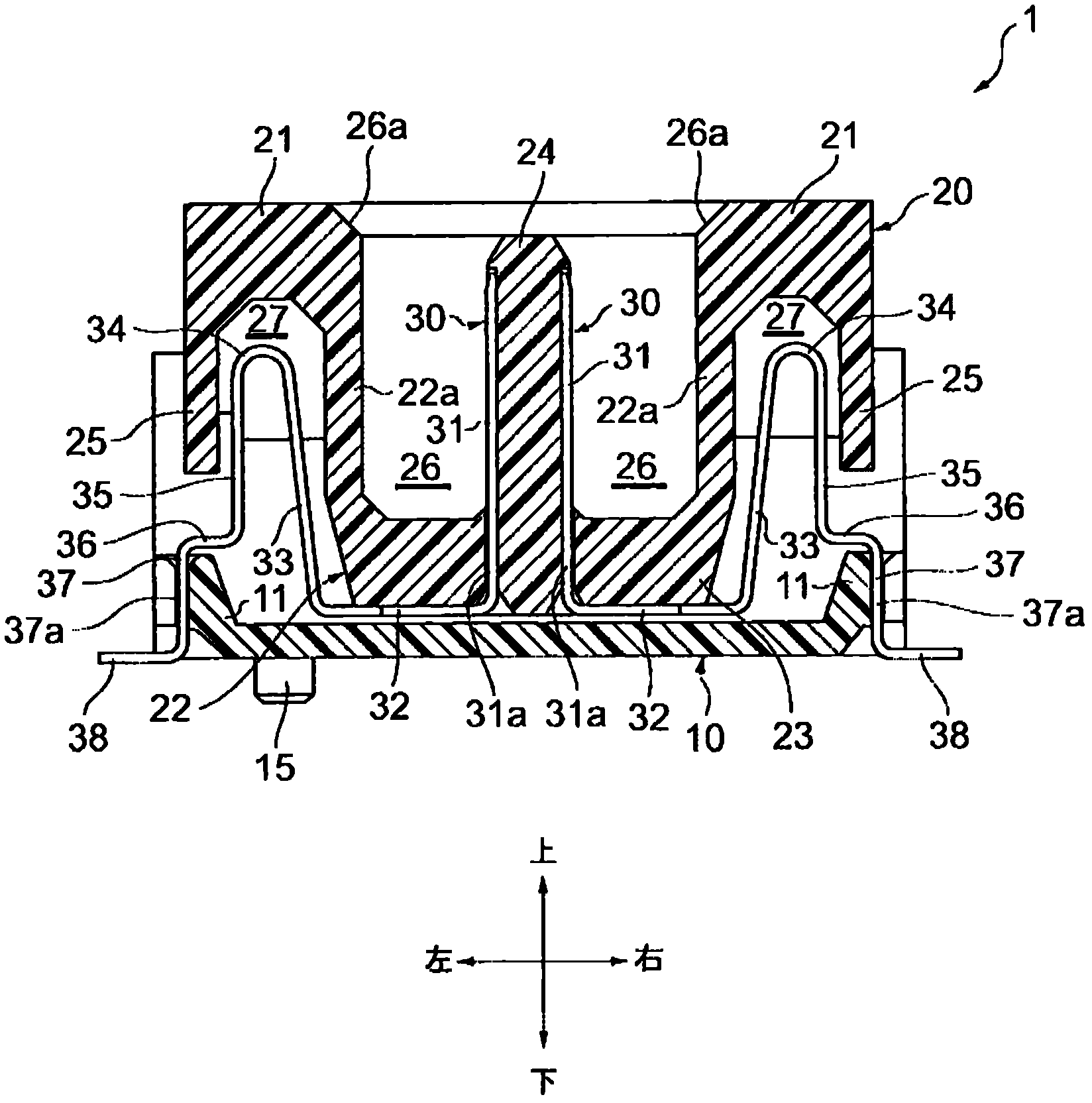

[0030] Embodiments of the present invention will be described below with reference to the drawings. Figure 1 to Figure 8 , Figure 9 (a) and Figure 14 A receptacle connector 1 and its components are shown as one embodiment of the floating connector of the present invention. figure 1 , Figure 9 (b) and Figure 10 ~ Figure 13 A plug connector 101 to be fitted into the receptacle connector 1 and its components are shown. In this embodiment, for the convenience of description, the front and rear, left and right, and up and down directions are defined and described by the arrow directions attached to each figure, but in actual use, they are not limited to these directions. This point is described in the claims. in the same way.

[0031] First, the component structure of the receptacle connector 1 will be described. Such as figure 1 with figure 2 As shown, the socket connector 1 has: a fixed base 10, the lower surface of which is fixed to the socket substrate 2; a mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com