Manual driving mechanism of off-circuit tap-changer

A tap changer and manual drive technology, which is applied in the direction of contact drive mechanism, transformer, electrical components, etc., can solve the problems of broken gears in the last stage, inconvenient shifting of transformer gears, complicated mechanism, etc., and achieves convenient manufacturing and installation. The structure of the manual mechanism is simple and the effect of reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples further describe the present invention, but the examples are only used to illustrate the present invention and not to limit the present invention.

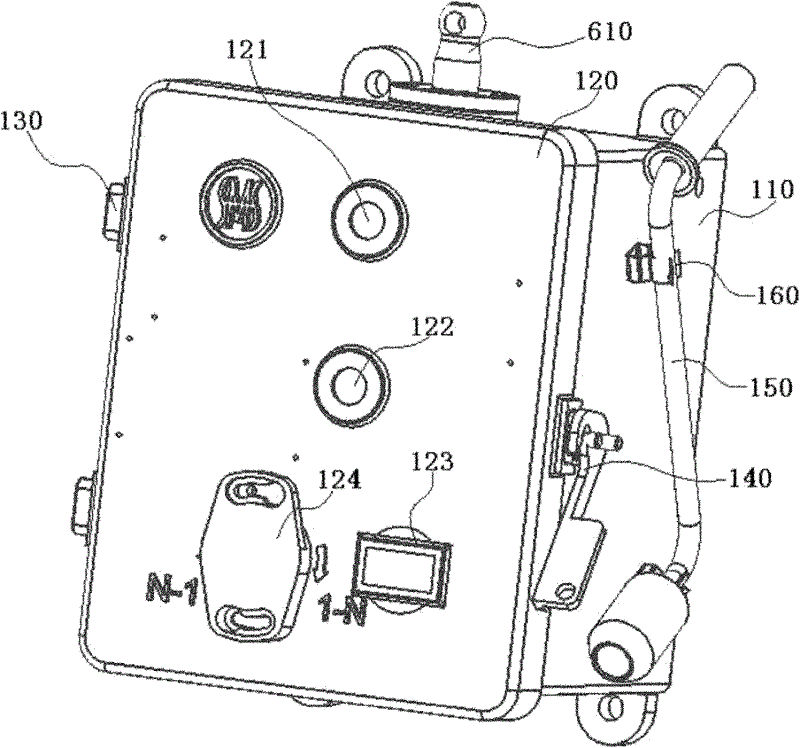

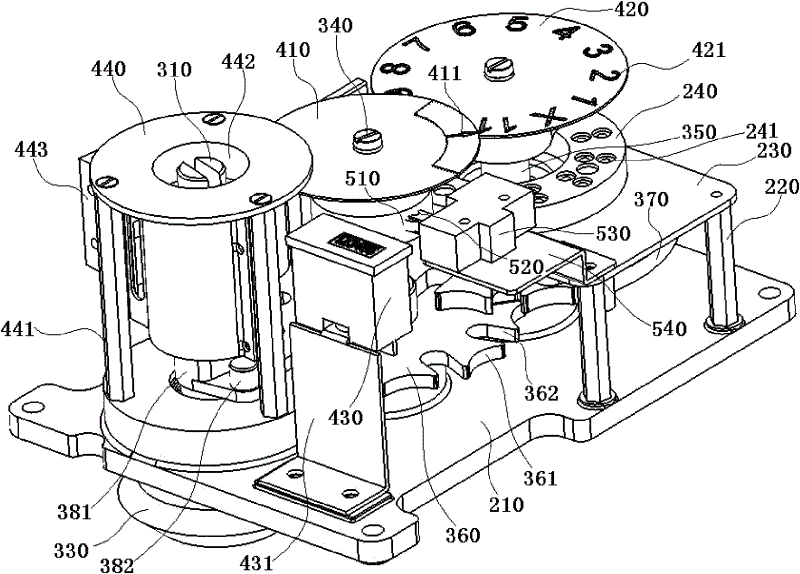

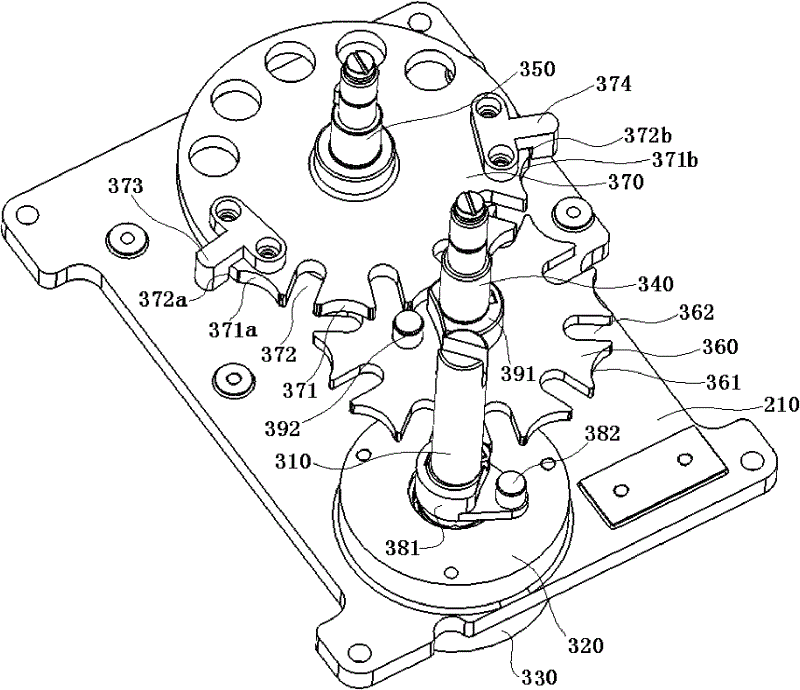

[0029] See figure 1 The manual drive mechanism of the non-excitation tap changer shown can be applied to the cage type non-excitation tap changer, and can also be used for the drum type non-excitation tap changer.

[0030] The manual drive mechanism of the off-excitation tap switch includes a box body 110 and a box cover 120. One side of the box cover 120 is hinged to the box body 110 through a hinge mechanism 130, and the other side is connected to the box body 110 through a door lock 140. The structure of the box body 110 and the box cover 120 of the present invention is basically similar to that of the existing manual drive mechanism. In order to facilitate manual operation, observation of gear positions, hand position and shift counting, a hand operation hole (under the cover 124), a view hole 121 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com