Pipeline quick-mounting and quick-dismounting connection assembly

A technology for connecting components and pipes, applied in mechanical equipment, couplings, etc., can solve the problems of time-consuming connection methods, weight reduction of pipe joint connections, and increased weight of pipeline systems, etc., to achieve the effect of convenient opening and inspection, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

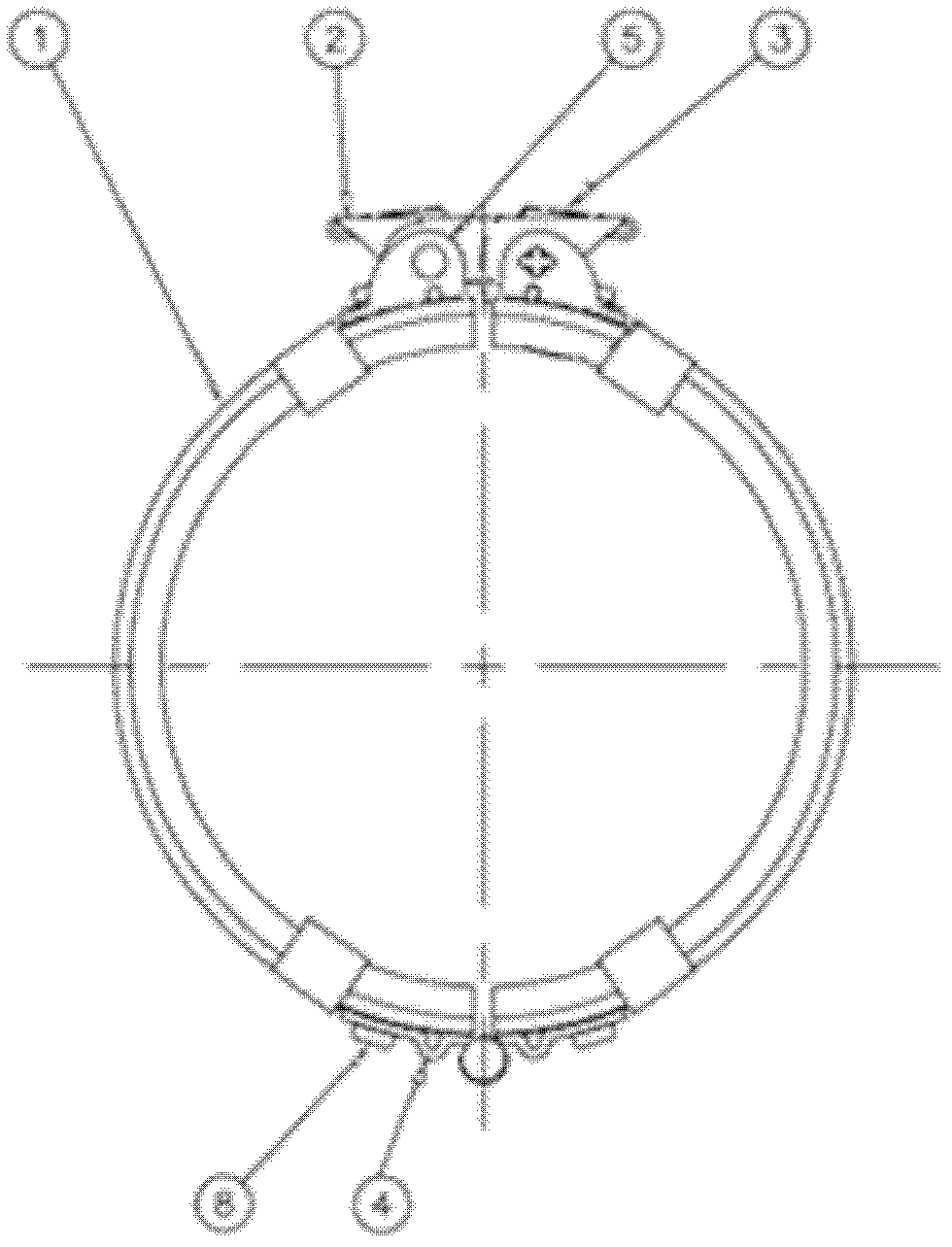

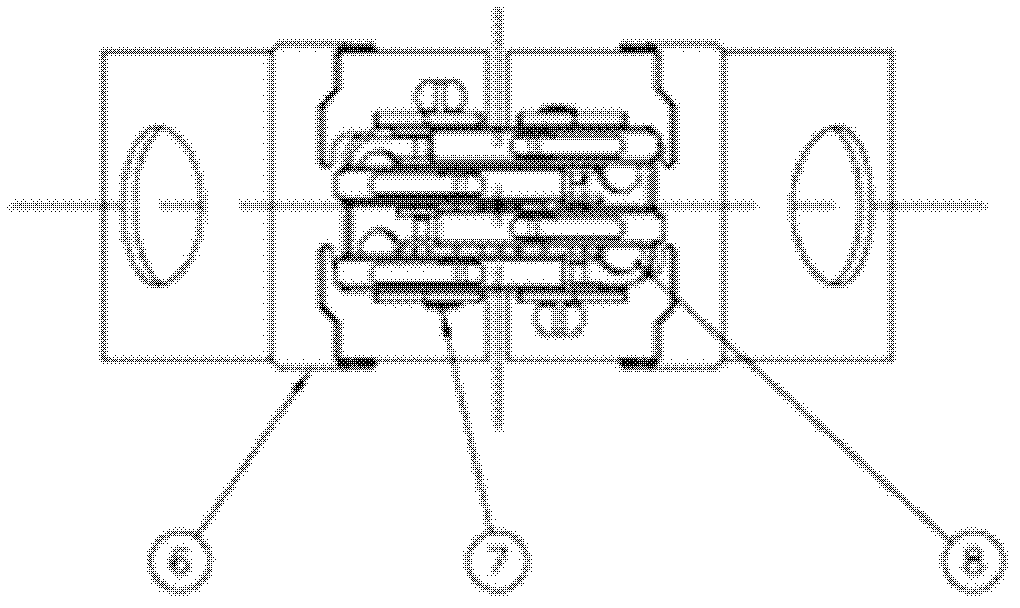

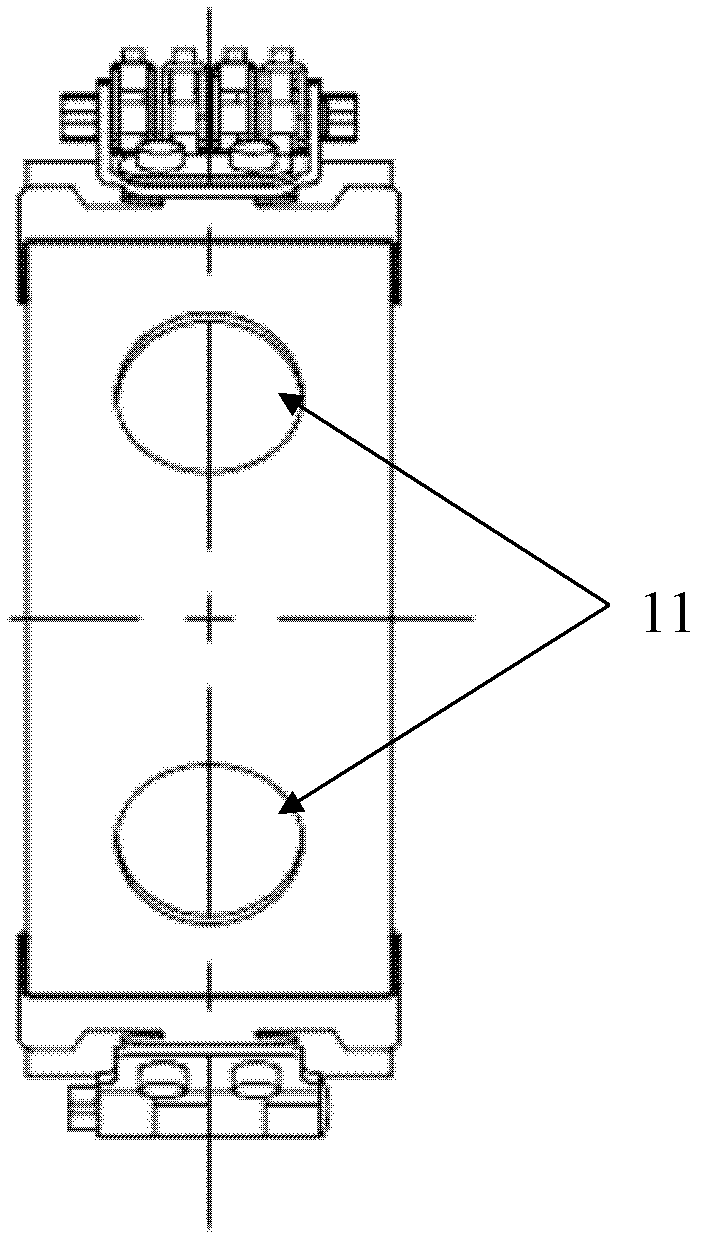

[0028] like Figure 1 to Figure 4 As shown, the present invention includes two semicircular retaining rings 1, one end of the two retaining rings 1 is hinged together by a hinge 4, and an axle seat 5 is fixedly installed on the outer side of the end of the other end, and each axle seat is fixed on each axle seat. A mandrel 7 is provided, and each mandrel 7 is respectively provided with at least one lock plate connected with the mandrel rotation through the shaft hole. There is a hook end, and there is a gap between the lock piece and the lock piece and between the lock piece and the shaft seat, exposing the shaft body of the mandrel, and the hook end can be hooked on the corresponding shaft body of another mandrel.

[0029] In order to prevent the locking piece from popping up automatically and causing the hook to be decoupled from the mandrel, an elastic back pressure device is also provided to prevent the locking piece from bouncing up and causing the hook to be disengaged f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com