Integral sludge distribution, cutting, throwing and receiving integrated machine

An integral and integrated machine technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of low drying efficiency, wet sludge cannot be effectively turned and thrown, and has no lifting function, etc., to achieve drying efficiency rising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

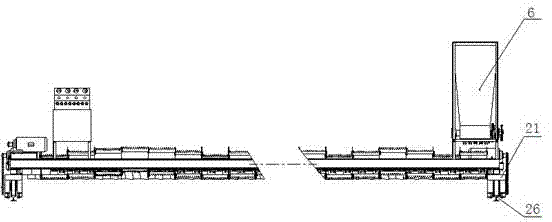

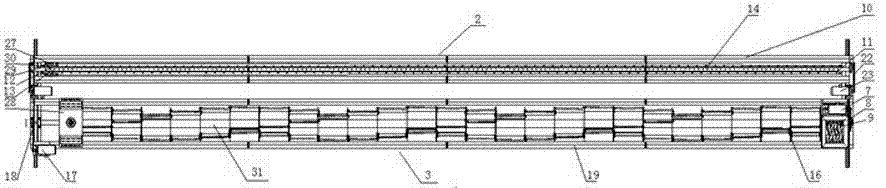

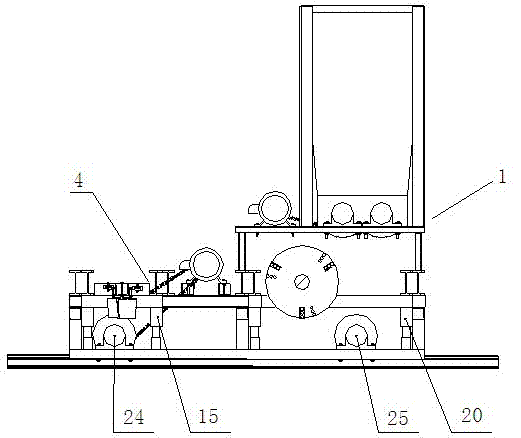

[0015] Such as Figure 1-3 As shown, an integral machine for sludge distributing, cutting, turning and receiving of sludge, including a feeding device 1 , a device for distributing, cutting and collecting materials 2 , a turning and throwing device 3 , a traveling mechanism 4 and a hydraulic mechanism 5 The unloading device 1 is connected with the material distribution, cutting and receiving device 2 through the walking mechanism 4, the turning and throwing mechanism 3 is connected with the feeding mechanism 1, and the hydraulic mechanism 5 is connected with the material distribution, cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com