Non-conductor contact electric power transmission method adopting redundant core protection

A technology for contacting electric energy and transmission methods, applied in transformer/inductor cores, circuits, inductors, etc., can solve problems such as poor handling, over-limit current, and drop in reluctance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

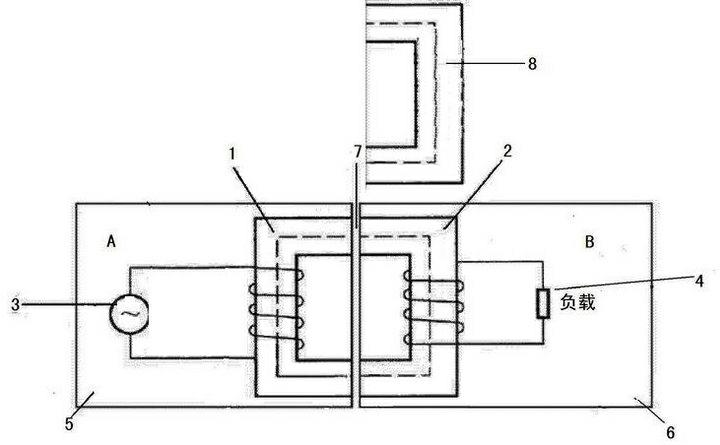

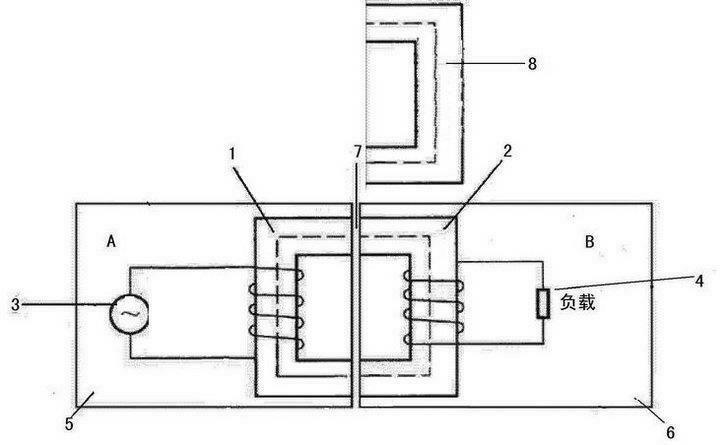

[0007] Such as figure 1 As shown, the non-conductor contact power transmission method using redundant magnetic core protection includes power supply terminal A and power consumption terminal B. Power supply terminal A includes an "E"-shaped power supply terminal iron core 1 and a winding on the power supply terminal iron core 1 The primary coil, the primary coil is connected to the AC power supply 3. The electrical terminal B includes the reverse "E"-shaped electrical terminal iron core 2 and the secondary coil wound on the electrical terminal iron core 2 and the secondary coil connected to both ends of the secondary coil Load 4, after the power supply terminal A and the power terminal B are connected, the power supply side core 1 and the power terminal core 2 form an almost complete "day"-shaped core, and the power supply side core 1 and the power terminal core 2 constitute Closed magnetic field line channel.

[0008] The power supply terminal A also includes the power supply t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com