Pre-pressed type air bearing

An air bearing and seat body technology, which is applied in the field of platform adjustment components, can solve the problems of complicated manufacturing and reduced stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

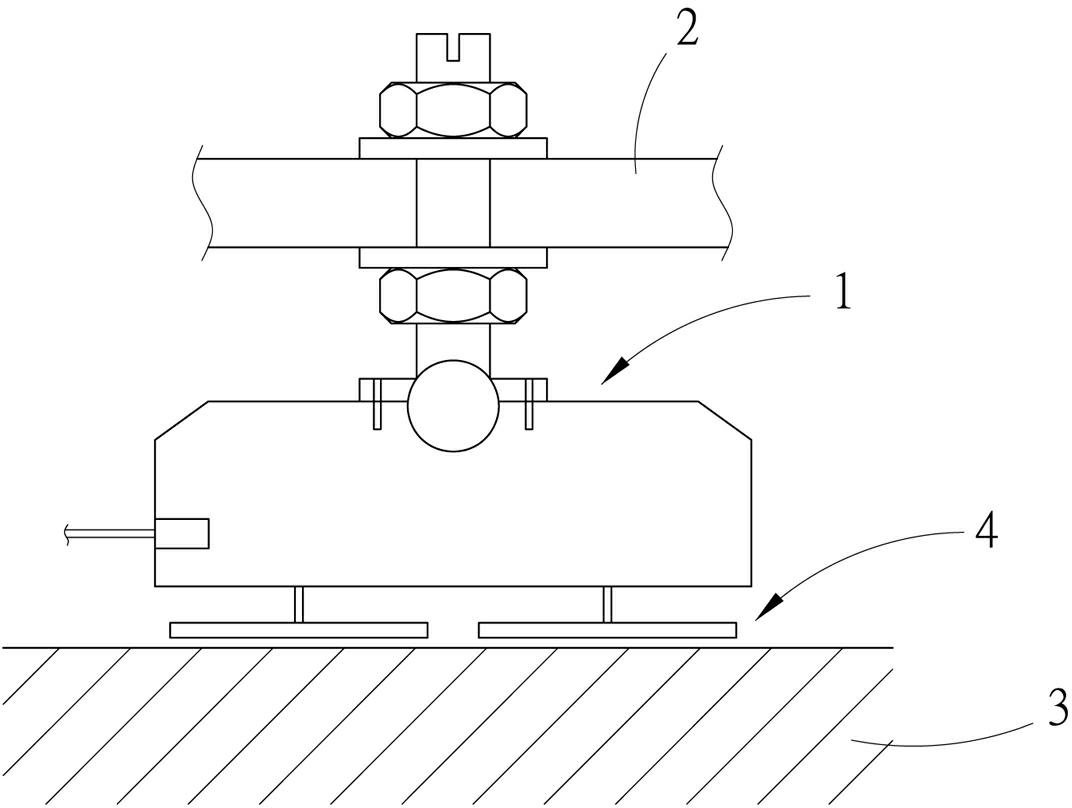

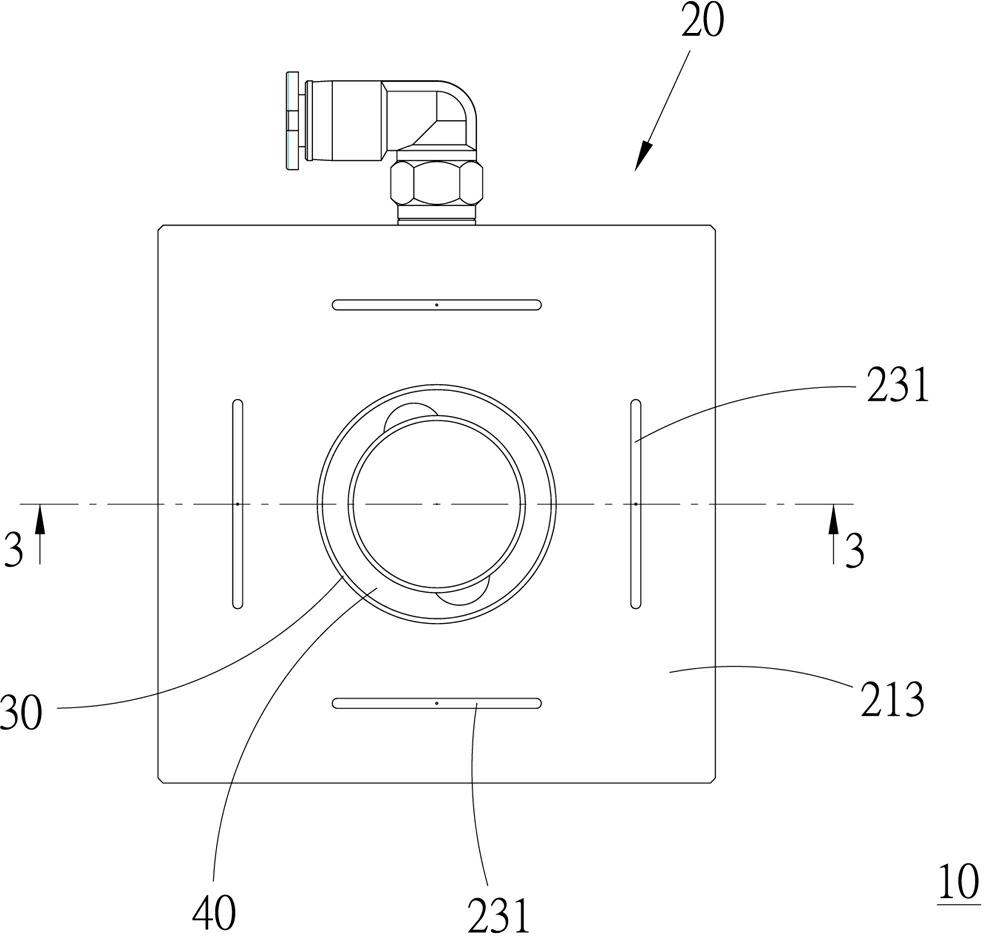

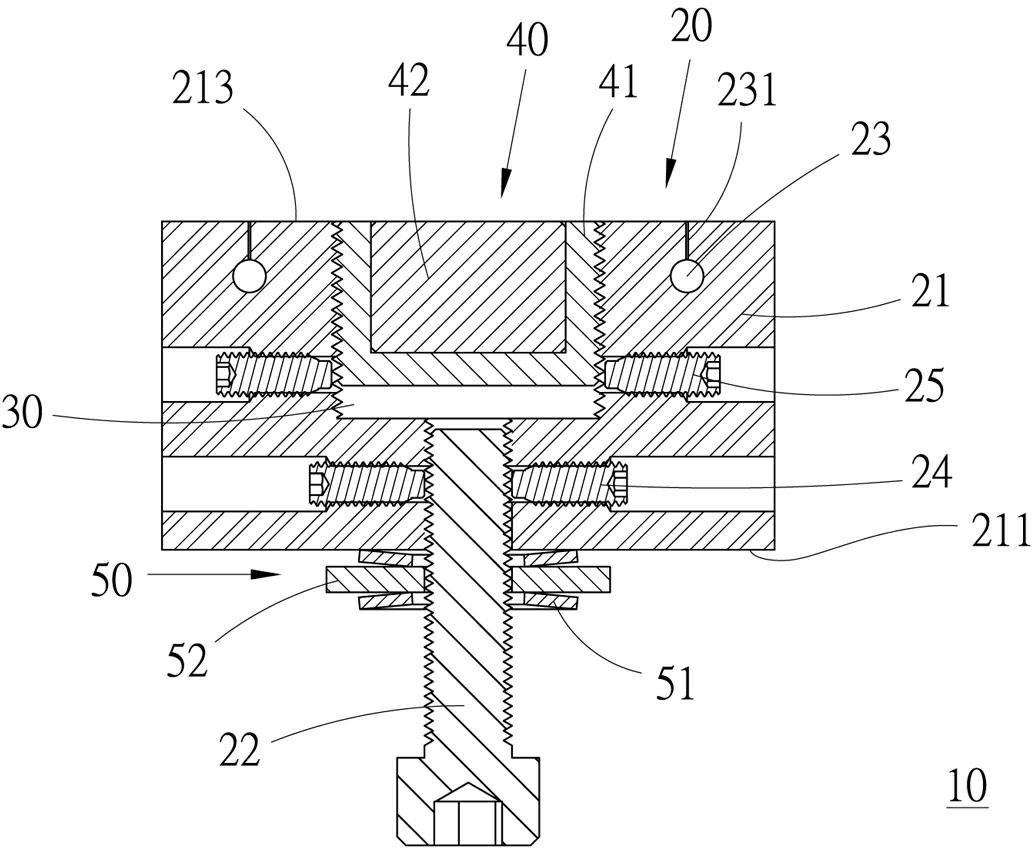

[0032] see Figure 2 to Figure 3 As shown, the preloaded air bearing 10 provided in a preferred embodiment of the present invention is used to be arranged on a platform (not shown in the figure), and mainly consists of a seat member 20, an accommodating portion 30, a The magnetic part 40 and an elastic part 50 are composed, wherein:

[0033] The seat part 20 has a square seat body 21, an adjustment part 22 composed of a screw, so that the long axis of the shaft corresponds to the geometric central axis of the seat body 21, and one end of the long axis of the shaft is screwed into a concave It is provided in the screw hole 212 of the connecting end surface 211 on the bottom side of the seat body 21, and the other end of the long axis of the shaft extends outward for a predetermined length from the connecting end surface 211 on one side of the seat body 21, and the extended end is slidably connected to the platform Above, at least one air passage 23 is provided inside the seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com