Novel submarine deep hole pressure maintaining and core drilling rig

A drilling rig and deep hole technology, which is applied in underwater drilling, earthwork drilling, extraction of undisturbed core devices, etc., can solve the problems of limited drilling depth of drill pipes, unfavorable deep hole drilling, and inability to store samples under pressure. The effect of improving coring efficiency, low cost of use, and simplifying the pressure-holding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

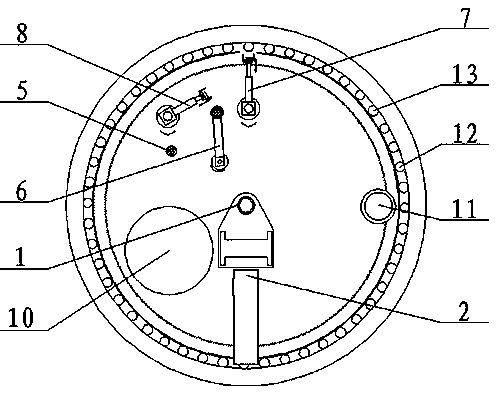

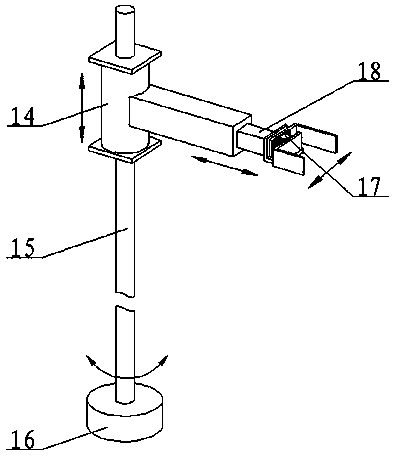

[0026] The present invention will be further described below in conjunction with accompanying drawing.

[0027] Such as figure 1 and figure 2 As shown, the new submarine deep-hole pressure-holding core drilling rig includes an outer frame 3, a support leveling mechanism 4, a drill pipe and core tube storage mechanism 5, a power head mechanism 1, a rope coring mechanism 2, a main manipulator 7, and an auxiliary manipulator 8. Assembly manipulator 6, pressure cap storage mechanism 9, hydraulic motor 11, drill pipe 13, core pipe 12 and hydraulic power system 10 of the drilling rig.

[0028] Such as figure 1 and figure 2 As shown, three supporting leveling mechanisms 4 are evenly distributed on the outer side of the cylindrical outer frame 3, and the supporting leveling mechanism 4 is composed of three identical telescopic supporting legs, and each supporting leg is composed of a hydraulic motor, a lead screw , sliders, long brackets, short brackets, hinges and related conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com