Series tannin extract raw material ultra-fine crushing preparation as well as combined and coupled preparation process and method for series tannin extract products

A technology of ultra-fine pulverization and product combination, which is used in chemical instruments and methods, natural resin technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

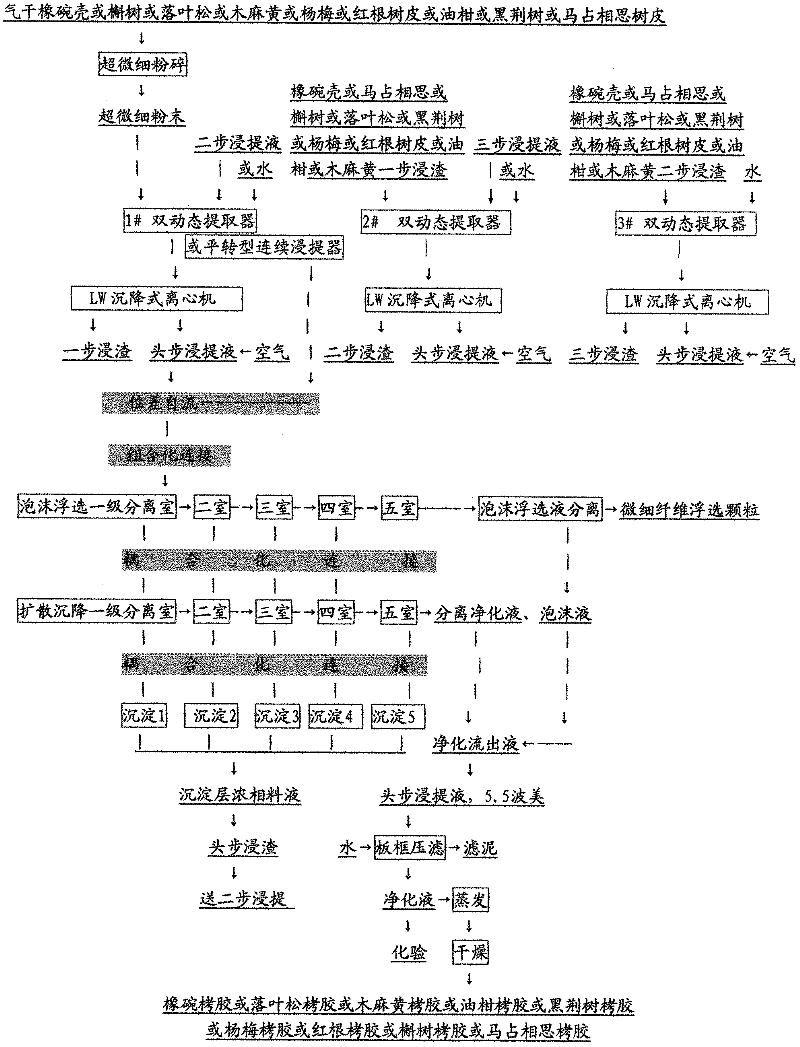

[0066] 1. A series of tannin extract raw material ultrafine pulverization preparation and its use in series tannin extract product combination, coupled preparation process and method, characterized in that it includes the following steps:

[0067] The first step is the selection of raw materials for extract production: oak shells, larch, casuarina, oil orange, black wattle, myrica tomentosa, red root, oak, and bark of acacia.

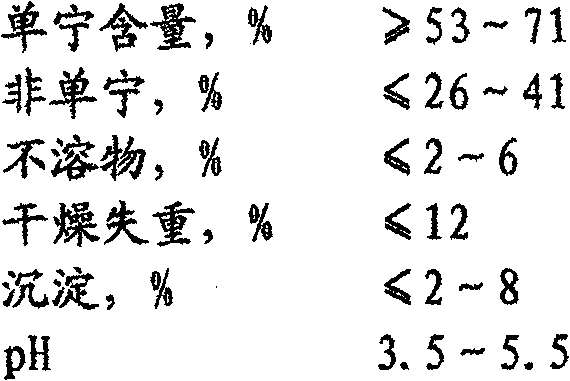

[0068] The second step is the selection of tannin extract varieties and their forms: powdered oak tannin extract, powdered larch tannin extract, powdered casuarina tannin extract, powdered citrus tannin extract, powdered black wattle extract, Powdered bayberry extract, powdered red root extract, powdered oak tree extract, powdered acacia extract.

[0069]In the third step, the raw materials of oak bowl shell, larch, casuarina, oil orange, black wattle, myrica tomentosa, red root, oak, and acacia bark and their ultrafine powder preparation: the collected...

Embodiment 2

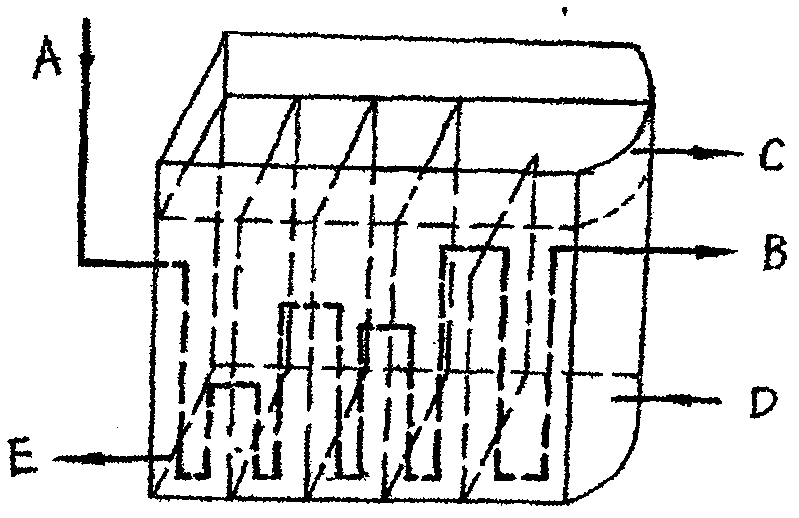

[0081] Weigh 500kg of 50-250 mesh rubber bowl shell ultrafine powder and place it in a 3000-liter glass-lined or stainless steel dynamic extraction tank with stirring and condenser. The extraction process adopts a low-temperature dual-dynamic three-tank three-step countercurrent extraction process or Flat type continuous extraction extraction process.

[0082] Low-temperature dual dynamic three-pot three-step countercurrent extraction process: one-step extraction temperature: 60-80°C, second-step extraction: 80-90°C, three-step extraction: 90-100°C. One-step extraction time: 1~1.5hr, two-step extraction time: 1~1.5hr, three-step extraction extraction time: 1~1.5hr. One-step extraction solid-liquid ratio: 1:5-6, two-step extraction solid-liquid ratio: 1:4-5, three-step extraction solid-liquid ratio: 1:3-4.

[0083] According to the above extraction process, add the superfine powder of rubber bowl shell and water into the double dynamic extractor according to the solid-liquid r...

Embodiment 3

[0097] Weigh 500kg of 50-250 mesh larch bark ultra-fine powder and place it in a 3000-liter glass-lined or stainless steel dynamic extraction tank with stirring and condenser. The extraction process adopts a low-temperature dual-dynamic three-pot three-step countercurrent extraction process or Flat type continuous extraction extraction process.

[0098] Low-temperature dual dynamic three-pot three-step countercurrent extraction process: one-step extraction temperature: 60-80°C, second-step extraction: 80-90°C, three-step extraction: 90-100°C. One-step extraction time: 1~1.5hr, two-step extraction time: 1~1.5hr, three-step extraction extraction time: 1~1.5hr. One-step extraction solid-liquid ratio: 1:5-6, two-step extraction solid-liquid ratio: 1:4-5, three-step extraction solid-liquid ratio: 1:3-4.

[0099] Flat type continuous extraction extraction process: extraction temperature: 70-100°C, extraction time: 8-10hr, extraction solid-liquid ratio: 1:8-10.

[0100] Add the lar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pulverization | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com