Shooting cylinder

A cylinder and cover technology, which is applied in the field of core-making auxiliary devices, can solve problems such as the need for a period of time to shoot the sand, the loss of moisture in the resin sand, and the removal of moisture in the resin sand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

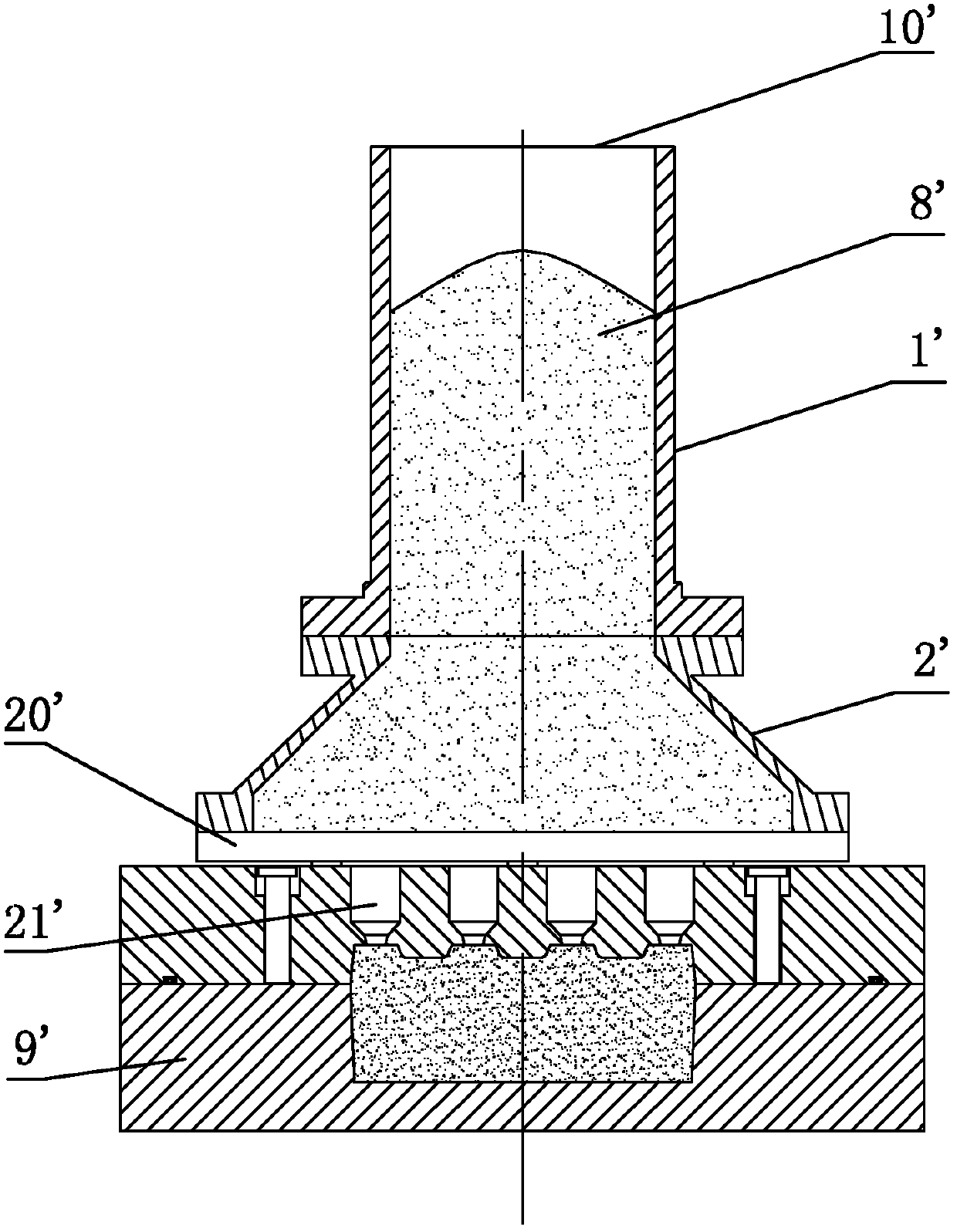

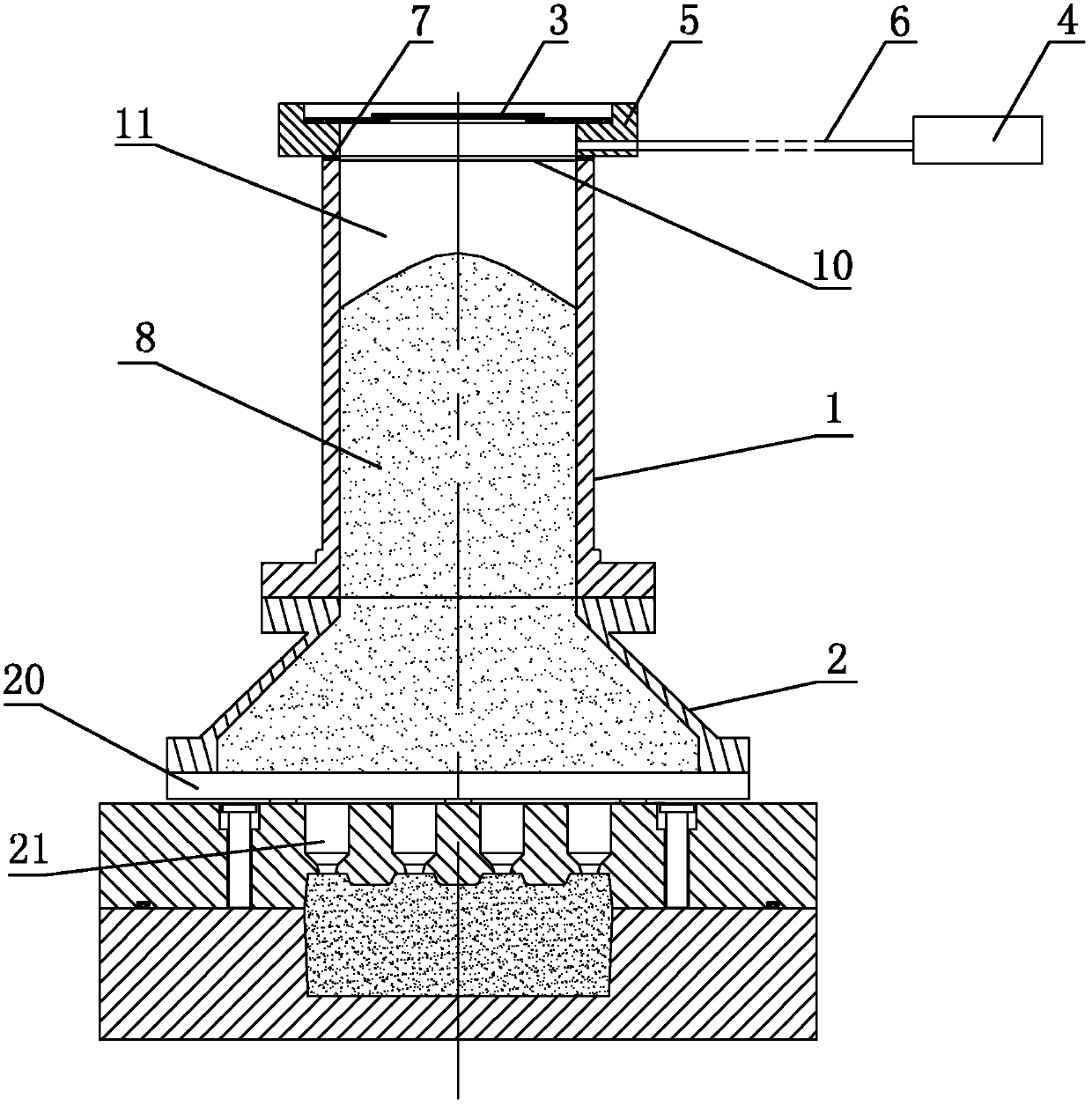

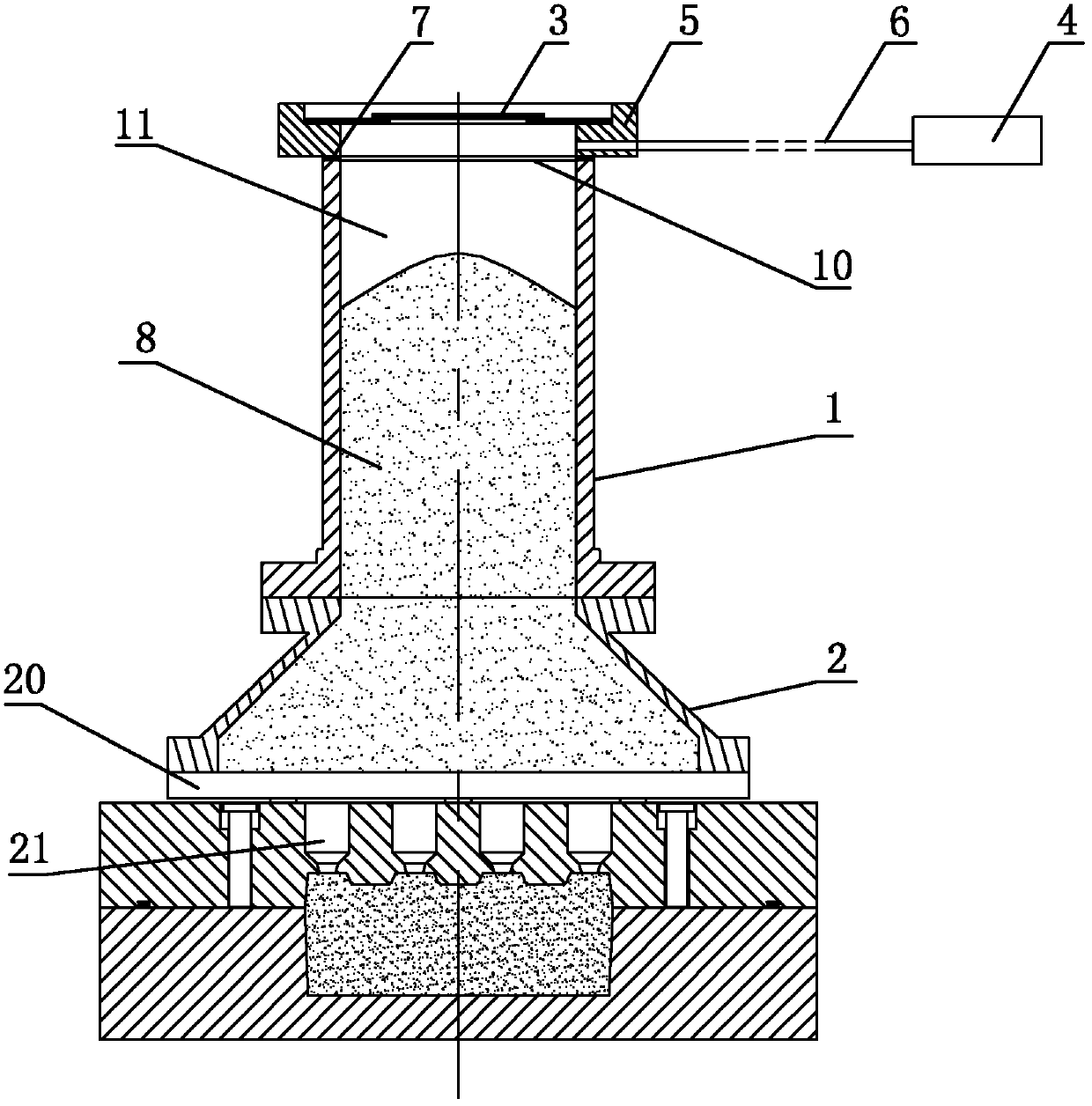

[0016] Such as figure 2 A shooting cylinder shown includes a cylinder body 1, a sand filling port 10 is opened on the upper part of the cylinder body 1, a shooting head 2 is connected to the lower part of the cylinder body 1, a shooting plate 20 is arranged on the shooting head 2, and a shooting plate 20 is connected to a Several nozzles 21. A cover 3 is provided on the upper part of the cylinder body 1 , and a closed cavity 11 capable of storing resin sand 8 is formed inside the cylinder body 1 through the cover body 3 , and a humidifying device 4 is connected in the closed cavity 11 .

[0017] In this embodiment, a fixed frame 5 is provided on the upper part of the cylinder body 1, and the cover body 3 is installed on the fixed frame 5, and the cover body 3 is an automatic retractable cover; the fixed frame 5 is provided with a pipeline 6, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com