Coating method and coating system having dynamic adaptation of the atomizer rotational speed and the high voltage

A sprayer and coating equipment technology, applied in the direction of liquid spraying equipment, coatings, spray discharge devices, etc., can solve the problems of unsatisfactory flexibility and dynamics, reduce unit cost, improve coating results, highly dynamic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

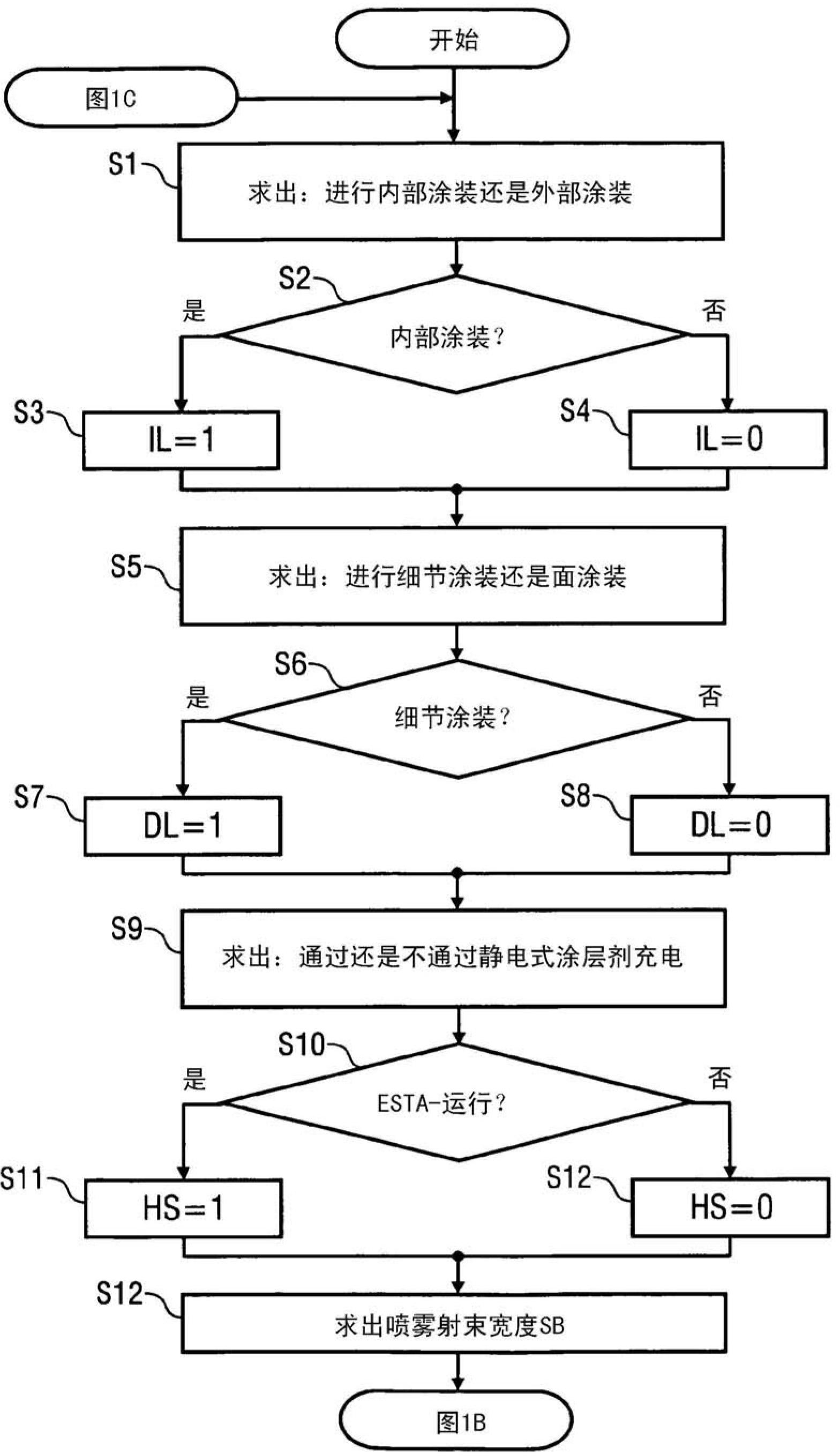

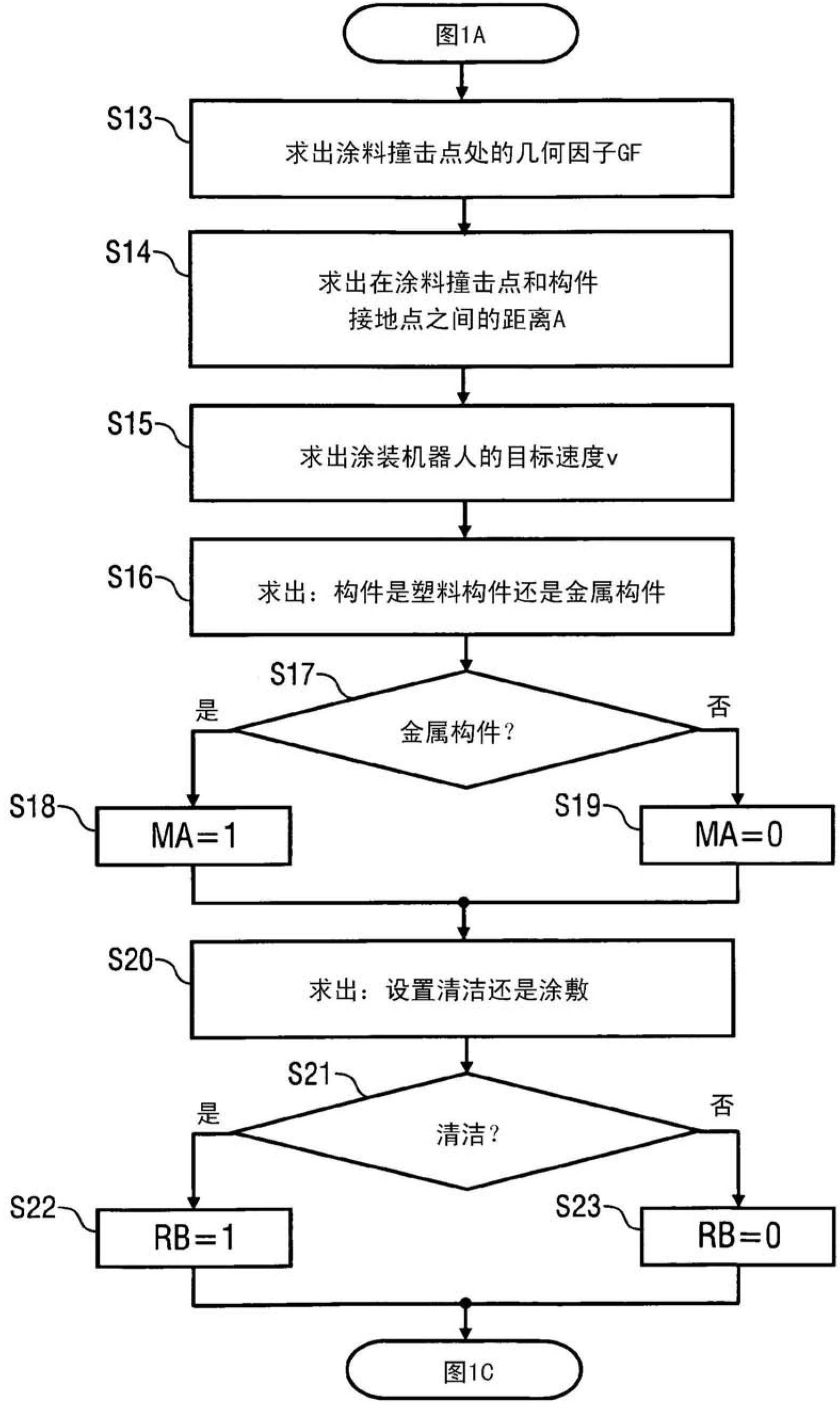

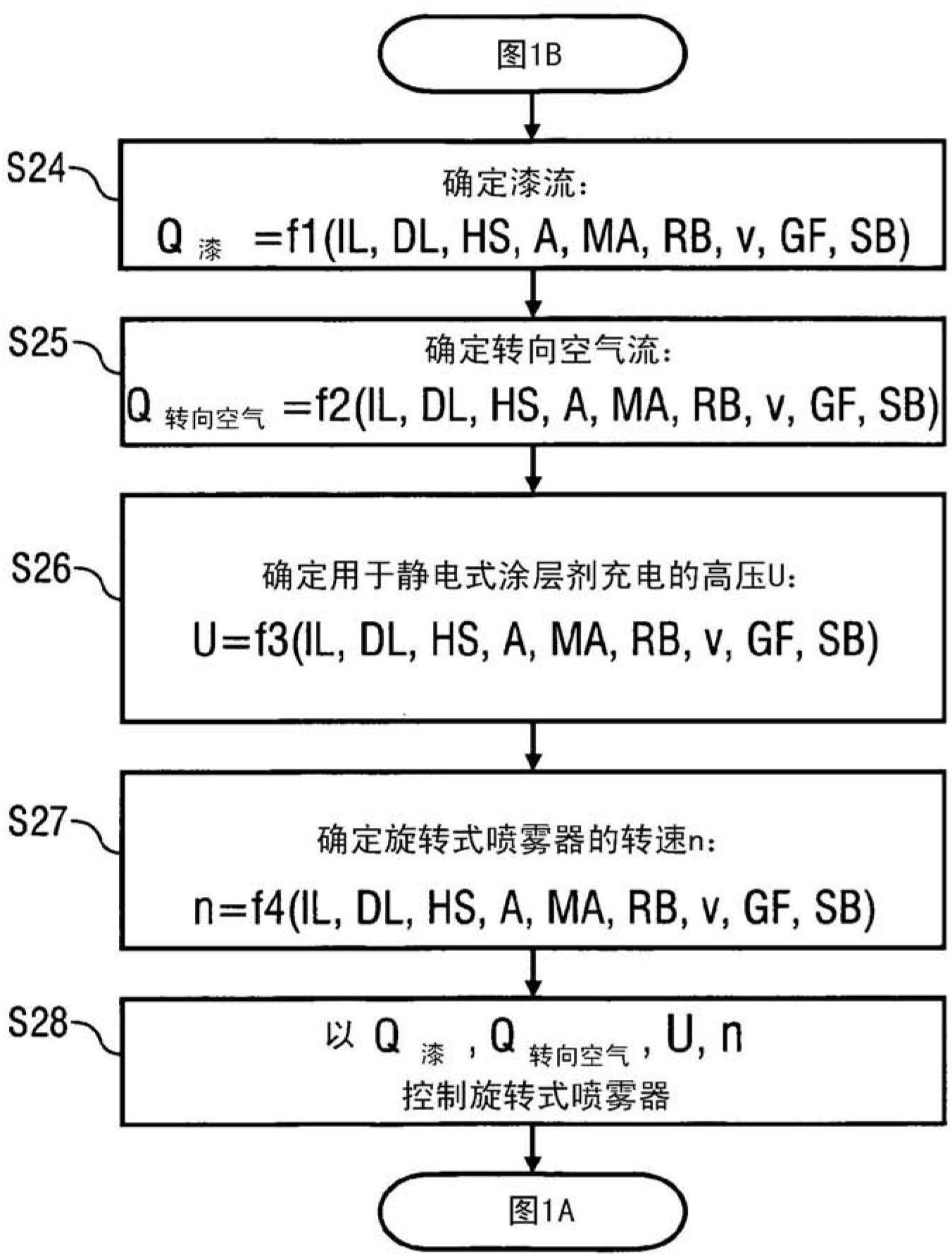

[0050] Figures 1A-1C The method steps according to the invention of the coating method are shown in the form of a flow chart. In this exemplary embodiment, the coating method is used for painting vehicle body components in a painting installation, wherein the painting is carried out by means of rotary sprayers which are each guided by a multi-axis painting robot. It is further mentioned that the method steps described in detail below are repeated continuously during the painting operation in order to enable a dynamic adaptation of the operating parameters of the rotary atomizer.

[0051] In a first step S1 it is initially ascertained whether the interior of the interior of the vehicle body component or the exterior of the vehicle body component is to be painted externally. This distinction is important because different requirements are placed on the operating parameters of the rotary sprayer (eg diverted air flow, high pressure) when painting the interior on the one hand and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com