Predication method of abrasion service life of foil sheet dynamic pressure radial gas bearing

A technology for gas bearings and bearing wear, which is applied in the direction of mechanical bearing testing, etc., and can solve problems such as bearing and foil surface wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

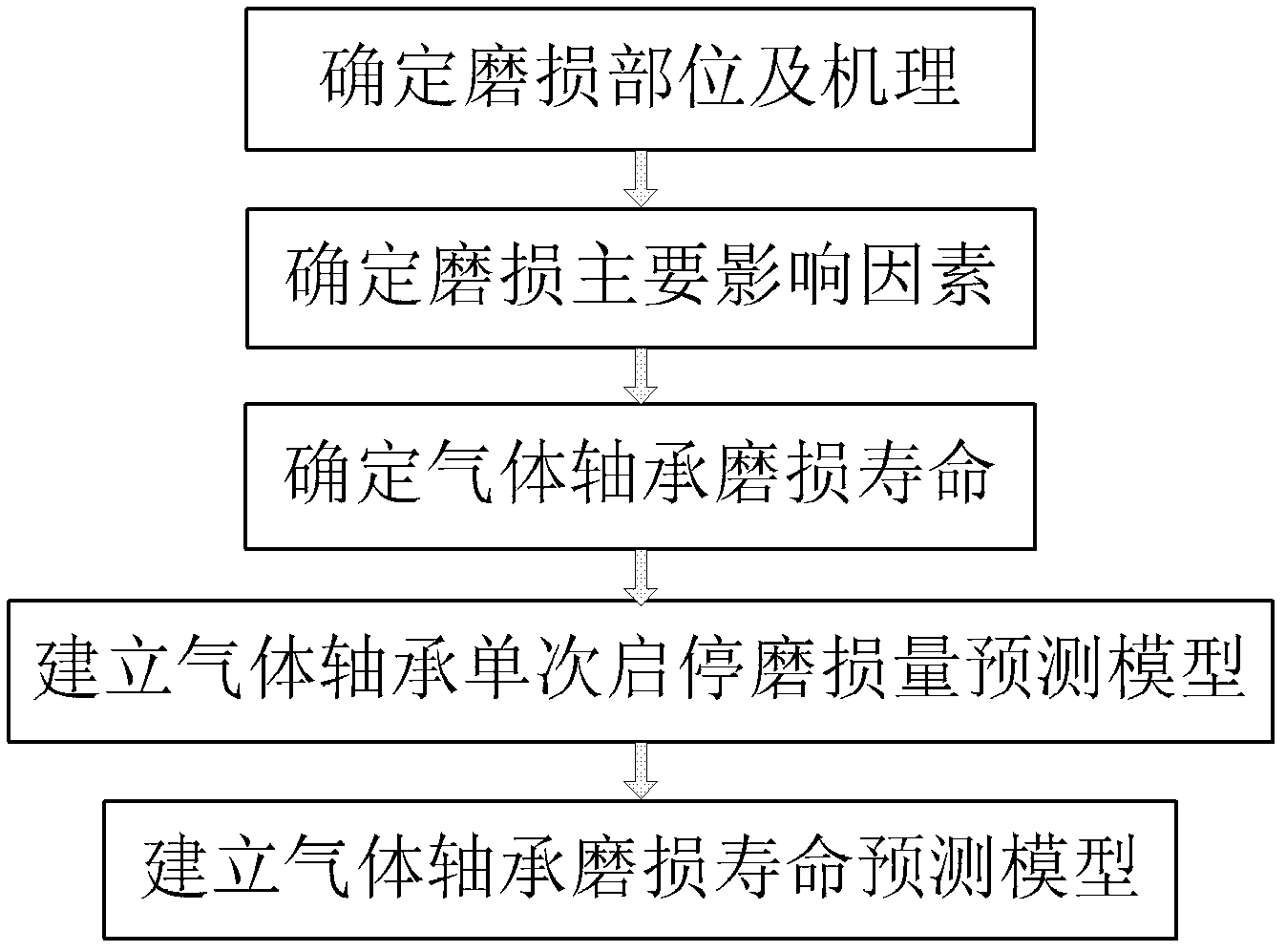

[0077] See image 3 , the present invention is a method for predicting the wear life of a foil dynamic pressure radial gas bearing, and the specific implementation method includes:

[0078] Step 1: Determine bearing wear mechanism

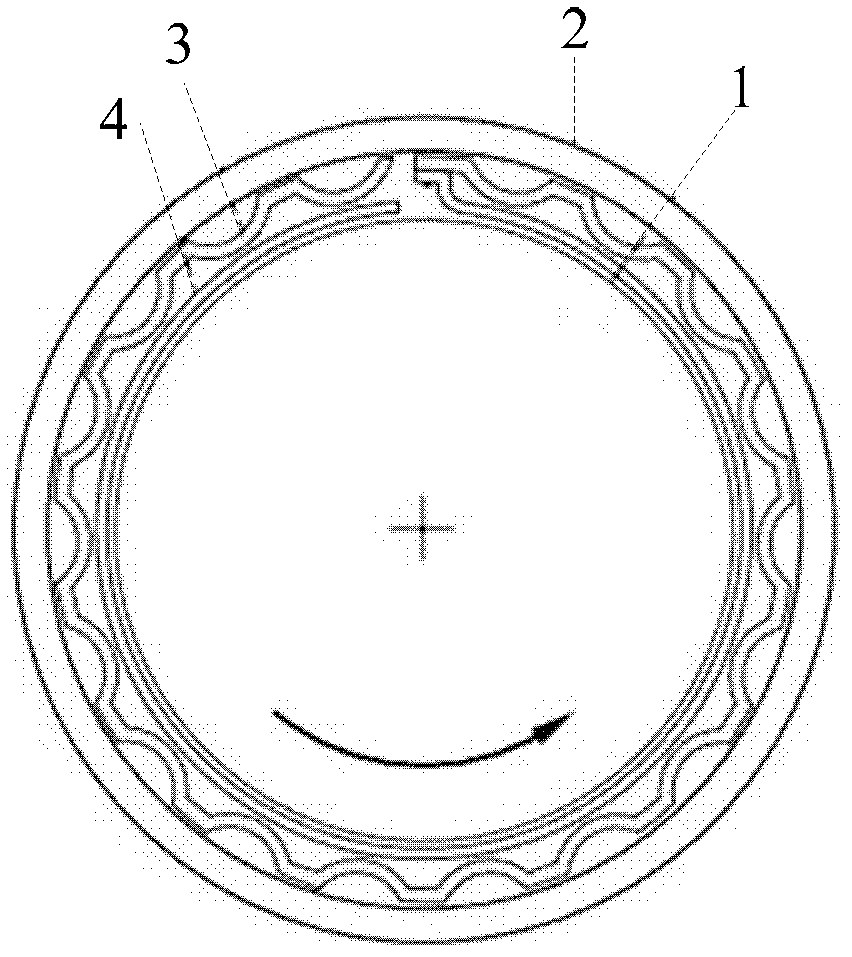

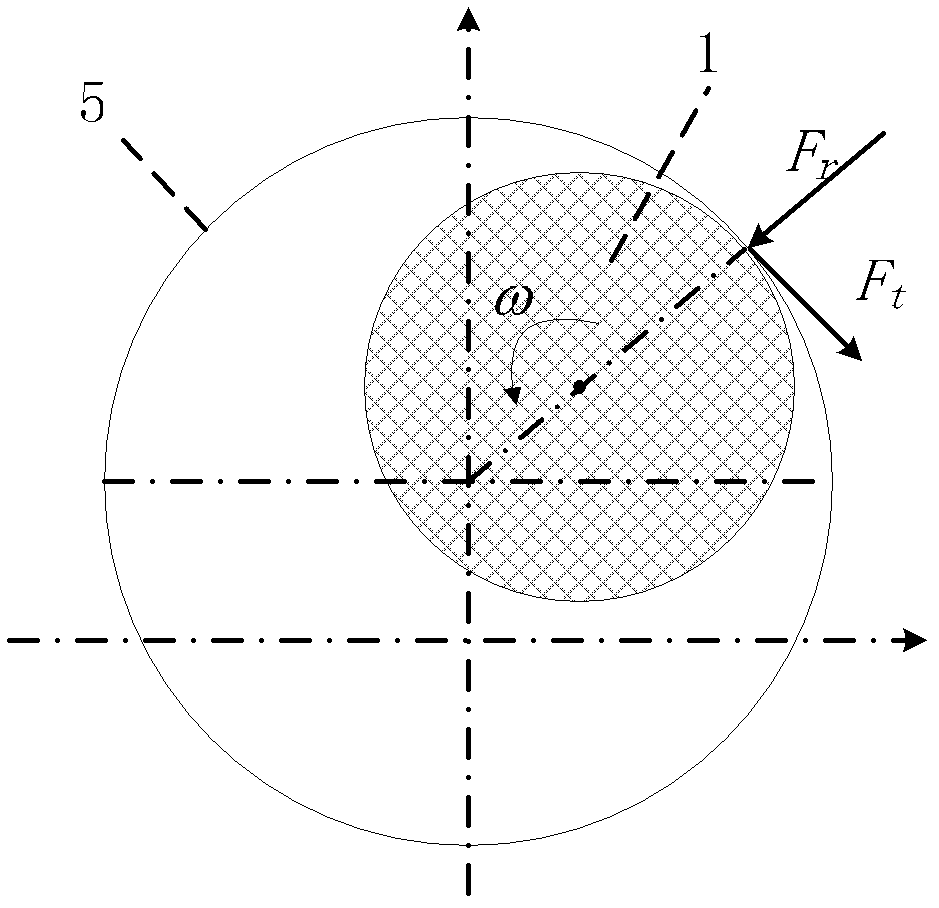

[0079] The foil dynamic pressure radial gas bearing uses the elastic deformation of the foil to form a wedge-shaped gap between the rotor and the working surface of the bearing to support the load. The foil dynamic pressure radial gas bearing structure consists of three parts: bearing outer ring, foil and bearing. The foil mainly provides support for the bearing. Taking the corrugated foil type dynamic pressure radial gas bearing as an example, see figure 1 . The foils in this type of bearing are divided into corrugated foils and flat foils. Their leading edges are spot welded or stuck on the outer ring shell of the bearing, which is the fixed end; the trailing edge is the free end. Corrugated foils provide support for a single flat foil. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com