Quilting seam pressing foot and method of using quilting seam pressing foot

A sewing machine presser foot and quilting technology, which is applied in the field of quilted fabric presser foot, can solve the problems of easy bending of stitches, easy wrinkling, and unsightly appearance of fabrics, and achieve the effect of speeding up and shortening the quilting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

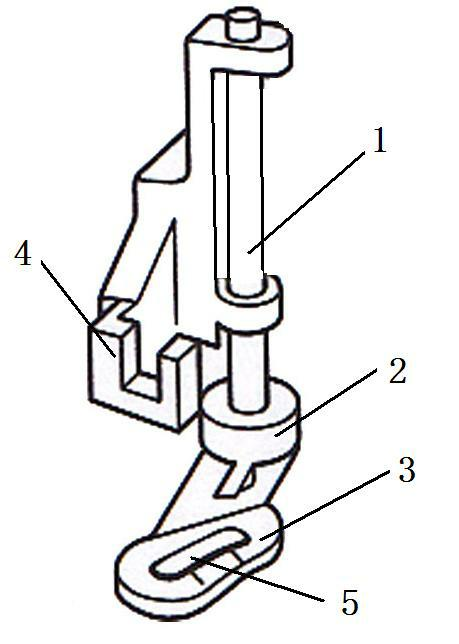

[0018] Such as figure 1 A quilting presser foot, characterized in that: the quilting presser foot includes: a support seat 1, a connecting seat 2, a base 3 and a connecting piece 4 for connecting the sewing machine presser foot bracket; the connecting seat 2 is cylindrical , for connecting the support seat 1 and the base 3; the base 3 is arc-shaped, and the base 3 is provided with a needle groove 5; the needle groove 5 is oval.

[0019] This embodiment also discloses a method for using the above-mentioned quilting presser foot, and the specific steps of the method are as follows:

[0020] (A) The sewing machine uses straight stitches;

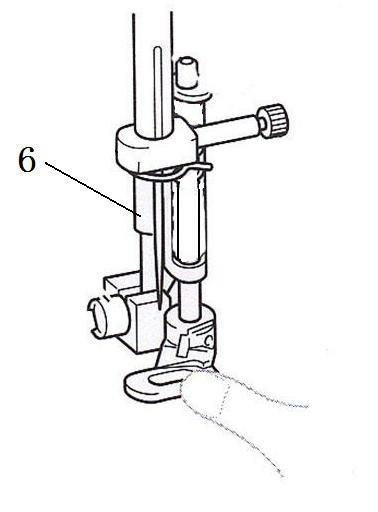

[0021] (B) Install the quilting presser foot, connect the connector 4 with the sewing machine presser foot support 6, and fix the quilting presser foot on the sewing machine presser foot support 6 (such as figure 2 shown);

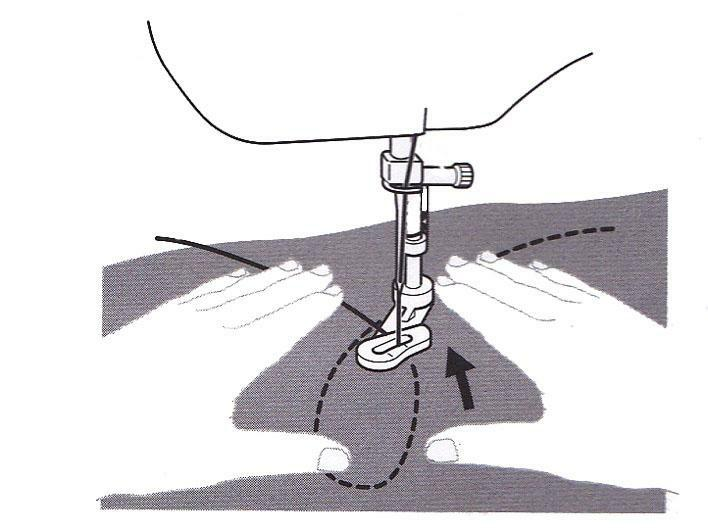

[0022] (C) Run the sewing machine at a low speed so that the sewing needle moves in the needle groove 5 without touch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com