Light-color tannin extracts and preparation method thereof

A technology of tannin extract and light color, which is applied in the field of light-color tannin extract and its preparation. It can solve the problems of failure to meet the requirements, the undisclosed preparation of light-color tannin extract ratio, and the high total chroma value of Luo Weibang, so as to improve the reaction Activity, reducing the degree of damage, reducing the effect of being oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

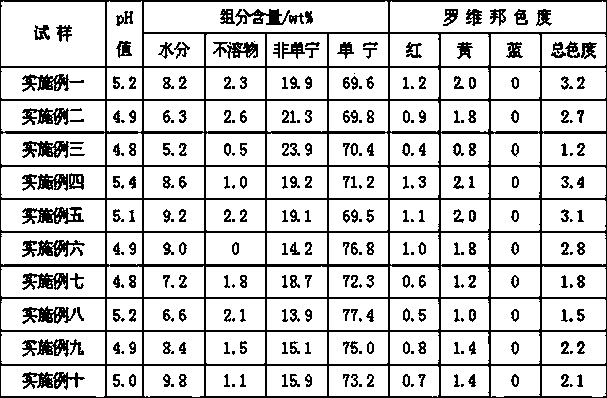

[0041] Dissolve 100 parts of Myrica tomentosa extract and 250 parts of water in a sealed reactor with a stirrer, add 3 parts of sodium formate, 5 parts of sodium hyposulfite, 12 parts of sodium bisulfite, 3 parts of oxalic acid, and 3 parts of citric acid, At a vacuum degree of 0.03Mpa, a temperature of 55°C, and a reaction time of 3 hours, the reaction is completed, and the obtained reaction product is a light-colored liquid tannin extract, or the reaction product is spray-dried to obtain a powdery light-colored tannin extract. After detection and analysis, the physical and chemical indicators of the tannin extract are shown in attached table 1.

Embodiment 2

[0043] Dissolve 100 parts of acacia extract and 250 parts of water completely in a sealed reaction kettle with a stirrer, add 0.5 parts of sodium hydroxide, 3 parts of pyrosulfite sodium, 2 parts of sulfurous acid, and 1 part of oxalic acid. 0.04 Mpa, temperature 60°C, reaction time 4 hours, the reaction is completed, the obtained reaction product is light-colored liquid tannin extract, or the reaction product is spray-dried to obtain powdery light-colored tannin extract. After detection and analysis, the physical and chemical indicators of the tannin extract are shown in attached table 1.

Embodiment 3

[0045] Completely dissolve 100 parts of Vitex bark extract and 250 parts of water in a sealed reaction kettle with a stirrer, add 1 part of potassium hydroxide, 6 parts of pyrosulfite sodium, 3 parts of sodium bisulfite, and 2 parts of acetic acid. The vacuum degree is 0.05 Mpa, the temperature is 65°C, and the reaction time is 5 hours. After the reaction is completed, the obtained reaction product is light-colored liquid tannin extract, or the reaction product is spray-dried to obtain powdery light-colored tannin extract. After detection and analysis, the physical and chemical indicators of the tannin extract are shown in attached table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com