Material mixed fermentation device

A fermentation device and material mixing technology, applied in the field of devices for material reaction, can solve the problems of inconvenient maintenance, high cost, complex structure, etc., and achieve the effects of low manufacturing cost, low cost and simple heating structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing implementation:

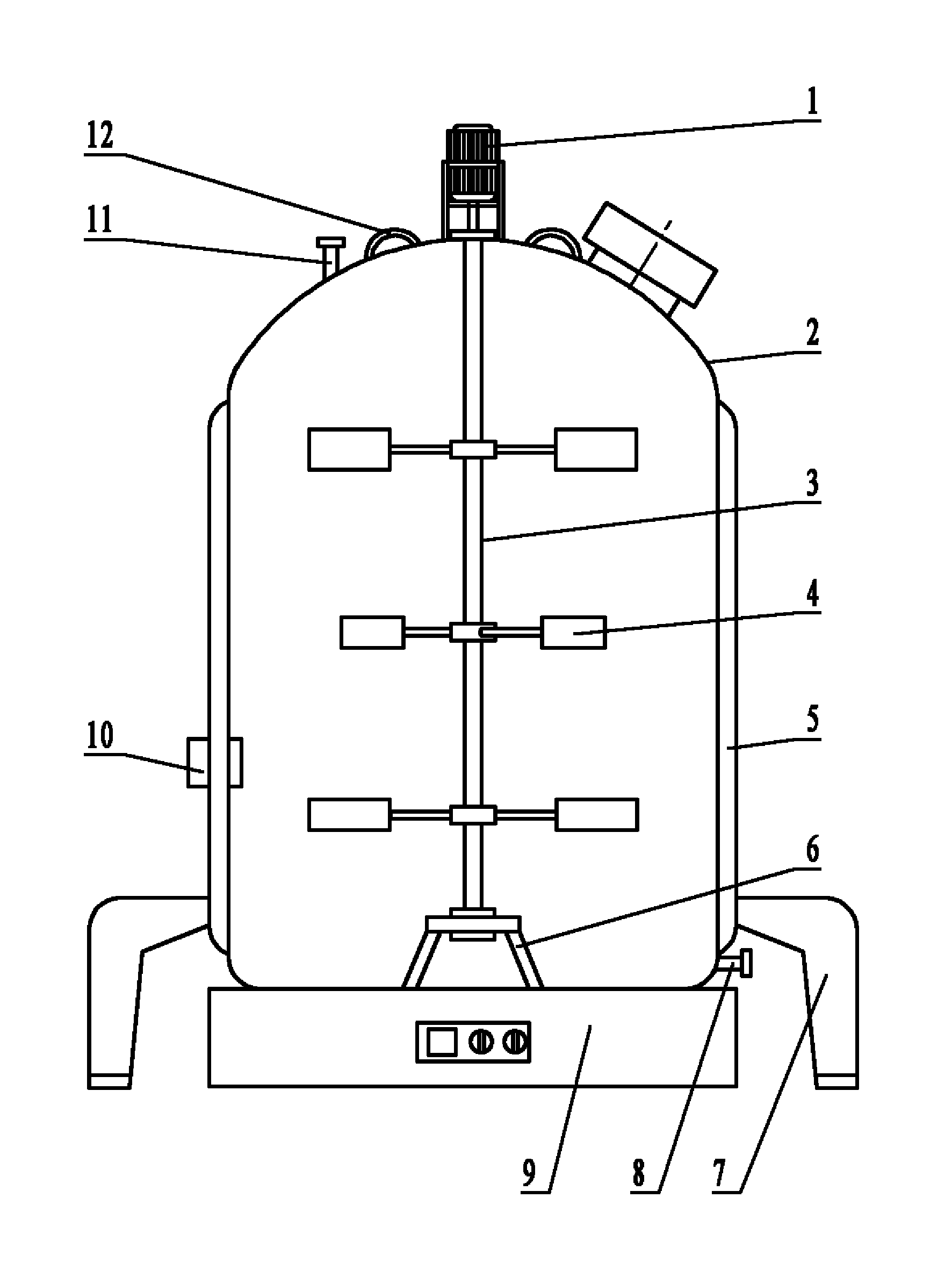

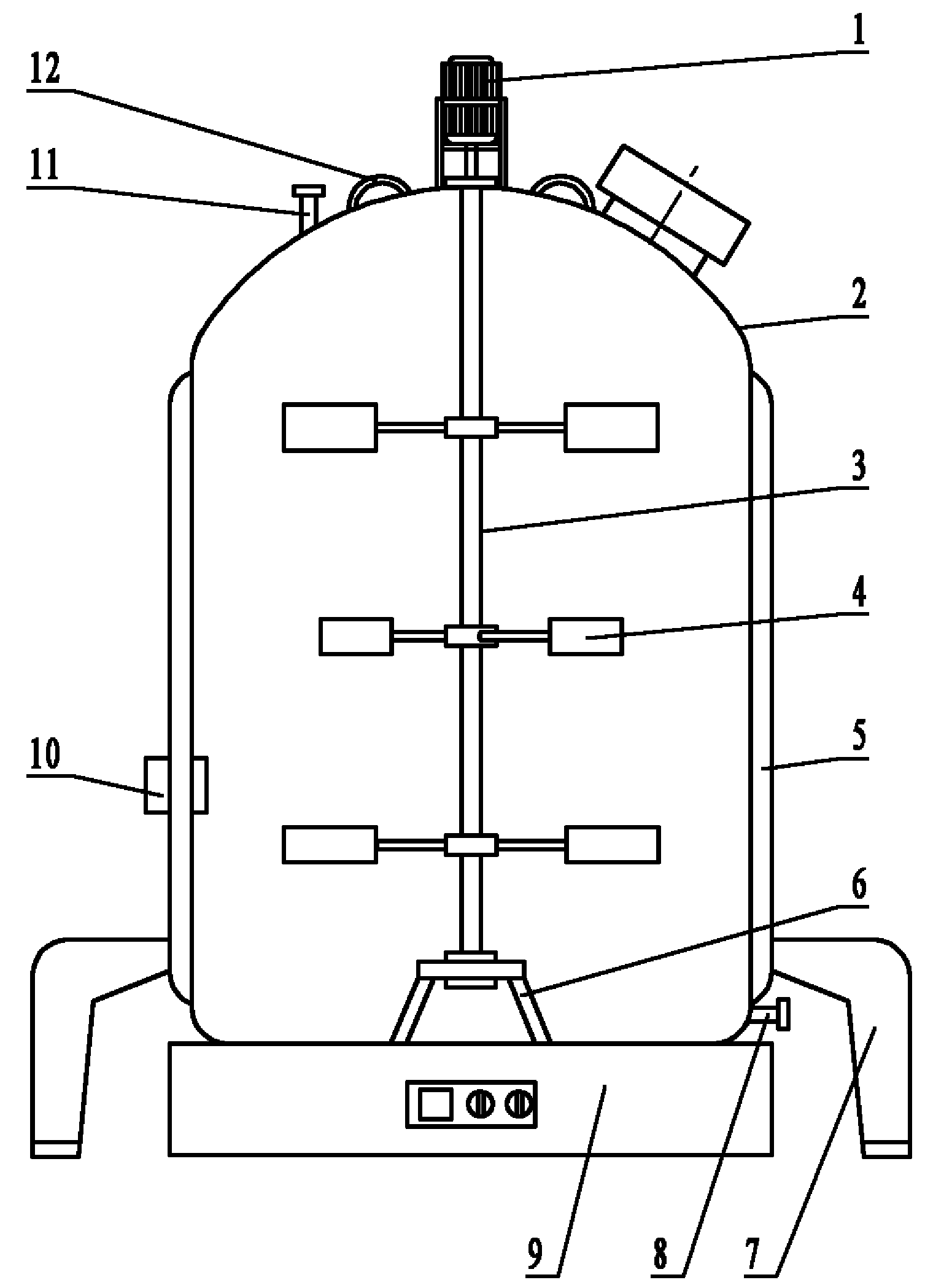

[0017] figure 1 The material mixed fermentation device shown includes a motor 1, a tank body 2 and an electric hob 9, the bottom of the tank body 2 is a flat structure so that the tank body 2 can be directly placed on the electric hob 9 for heating, and the top of the tank body 2 A feed port 11 , lifting lugs 12 and manholes are provided, and the lifting lugs 12 are symmetrically arranged on both sides of the tank body 2 . The side wall of the tank body 2 is provided with a discharge port 8 near the bottom of the tank, and this setting position can meet the discharge requirements without affecting the placement and heating of the electric hob 9 . The motor 1 is installed at the top center of the tank body 2. The tank body 2 has a built-in rotating shaft 3 linked with the motor 1. There are several groups of cross-arranged blade groups connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com