Transversely-circular material pushing screw

A feeding screw and screw technology, which is applied in the field of horizontal circulation pushing screw, can solve the problems of affecting the distribution of powder, affecting the accuracy of feeding, and uneven looseness of powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

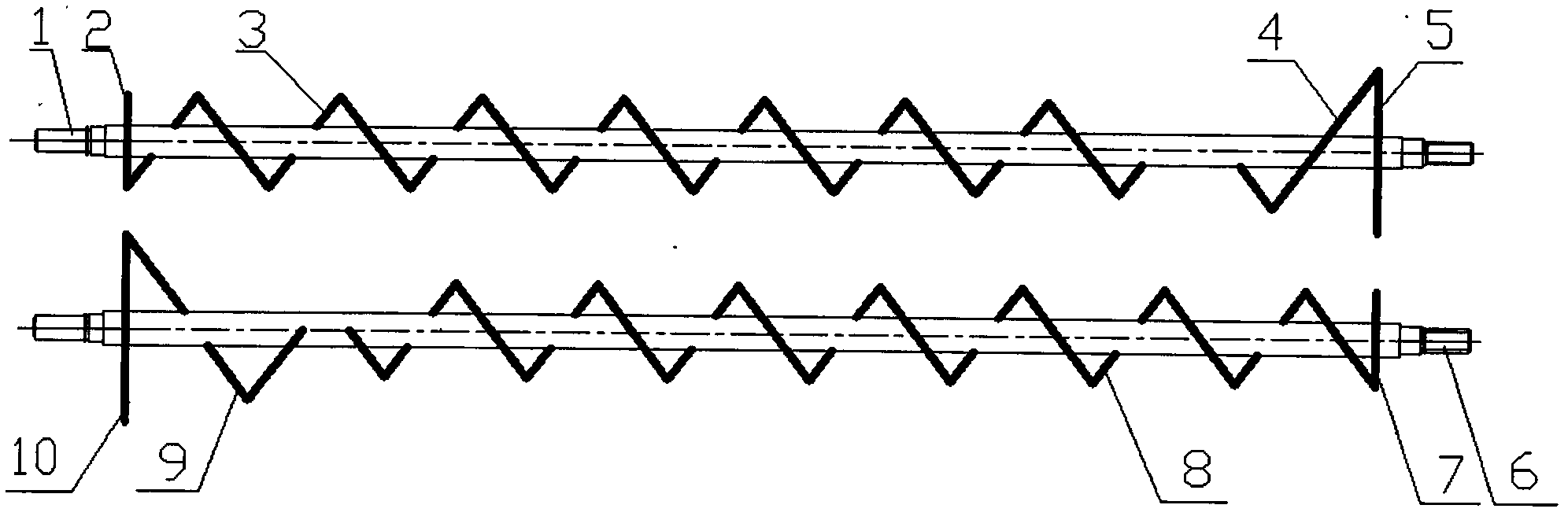

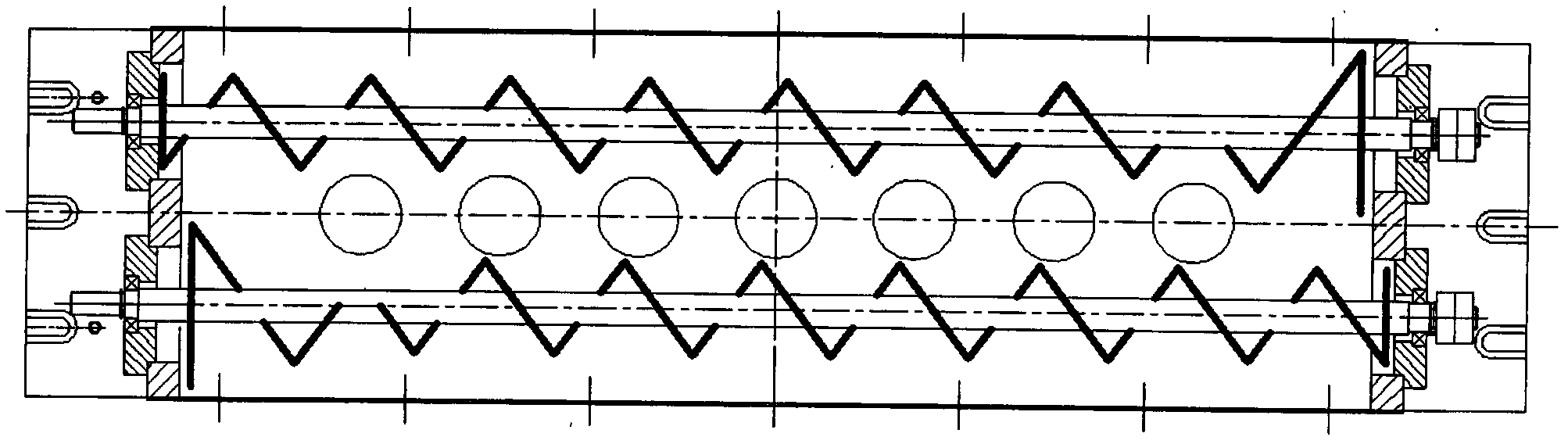

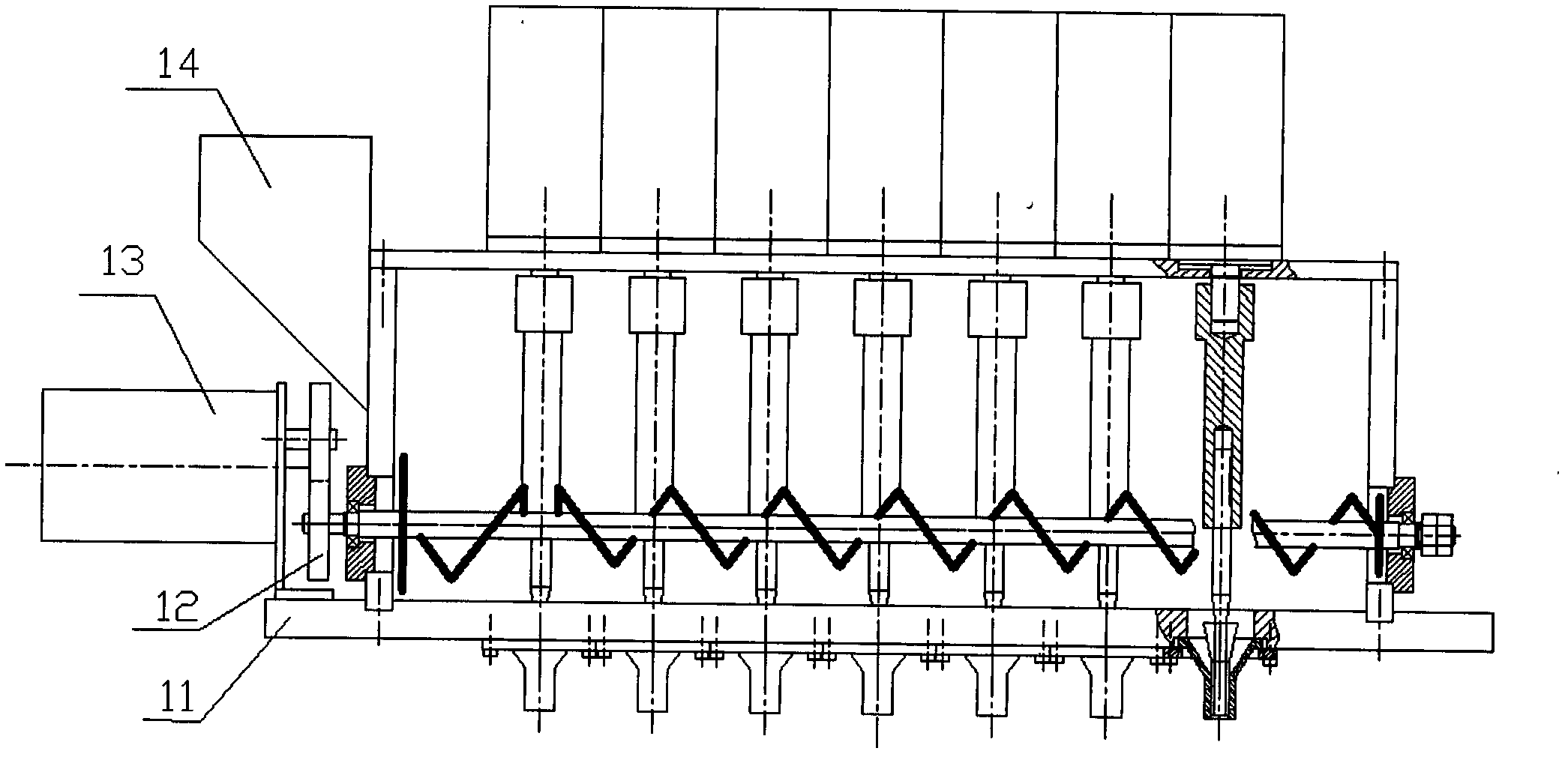

[0014] A horizontal circulation pusher screw, which is composed of a feed screw (1) and a return screw (6), is characterized in that the left end of the main journal of the feed screw (1) is provided with a circular stopper (2) and is equal to the right-handed helix piece (3) is connected, the right end of the main journal is provided with a large baffle (5) and is connected with the left-handed conical spiral piece (4); the left end of the main journal of the return screw (6) is provided with a large baffle (10) and is connected with the right-handed The conical helical pieces (9) are connected, and the right end of the main journal is provided with a circular baffle (7) and is connected with the left-handed equal-diameter helical piece (8).

[0015] The outer diameters of the circular baffle (2), the right-handed equal-diameter spiral (3), the circular baffle (7) and the left-handed equal-diameter spiral (8) are the same; the large baffle (5) and the large baffle (10) The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com