Saucer-shaped aircraft

A saucer-shaped aircraft and guide vane technology, applied in the field of aircraft, can solve problems such as increased energy consumption, difficulty in speed adjustment, waste of resources, etc., and achieve the effects of reduced air resistance, novel structural design, and stable hovering in the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are further described in detail in conjunction with the accompanying drawings

[0031] Working principle of the present invention:

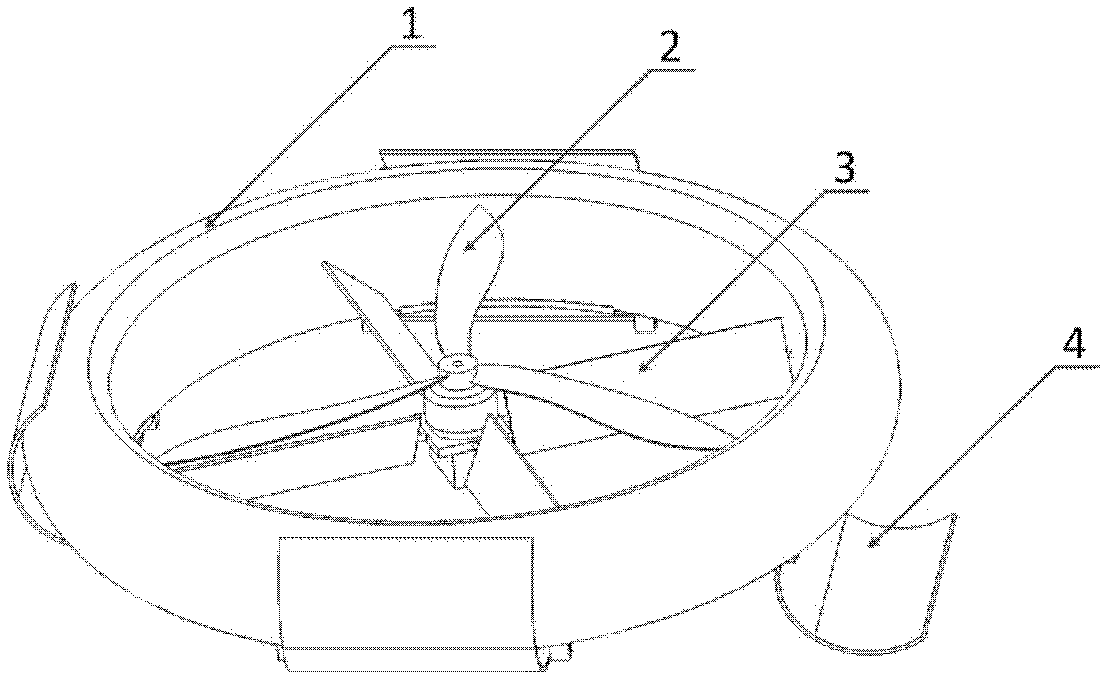

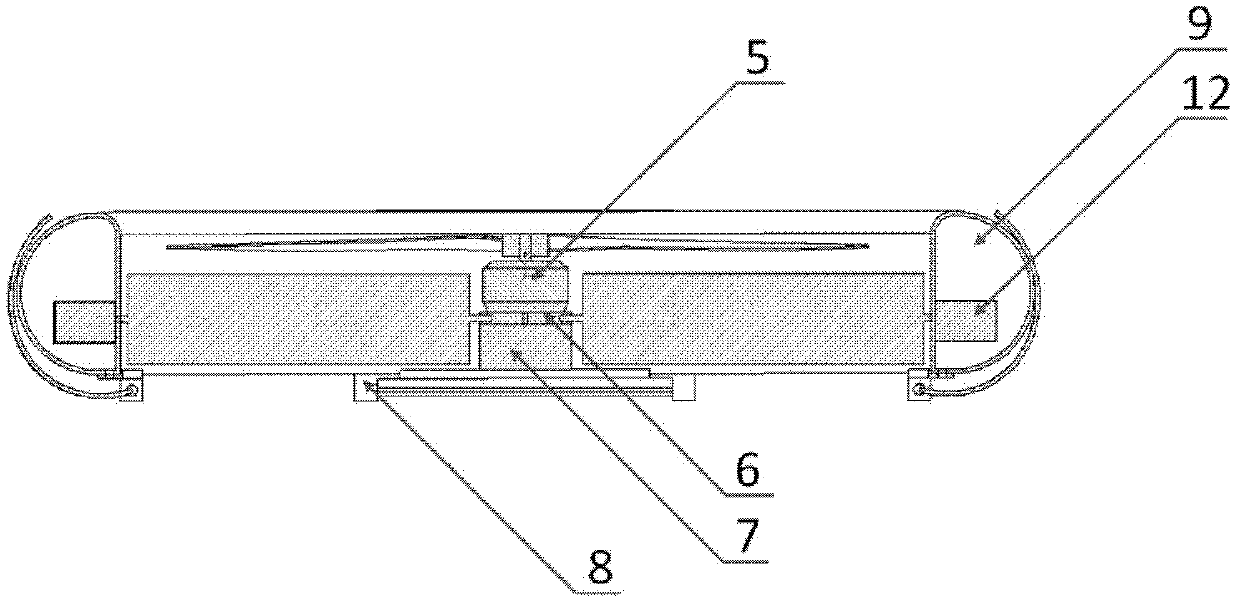

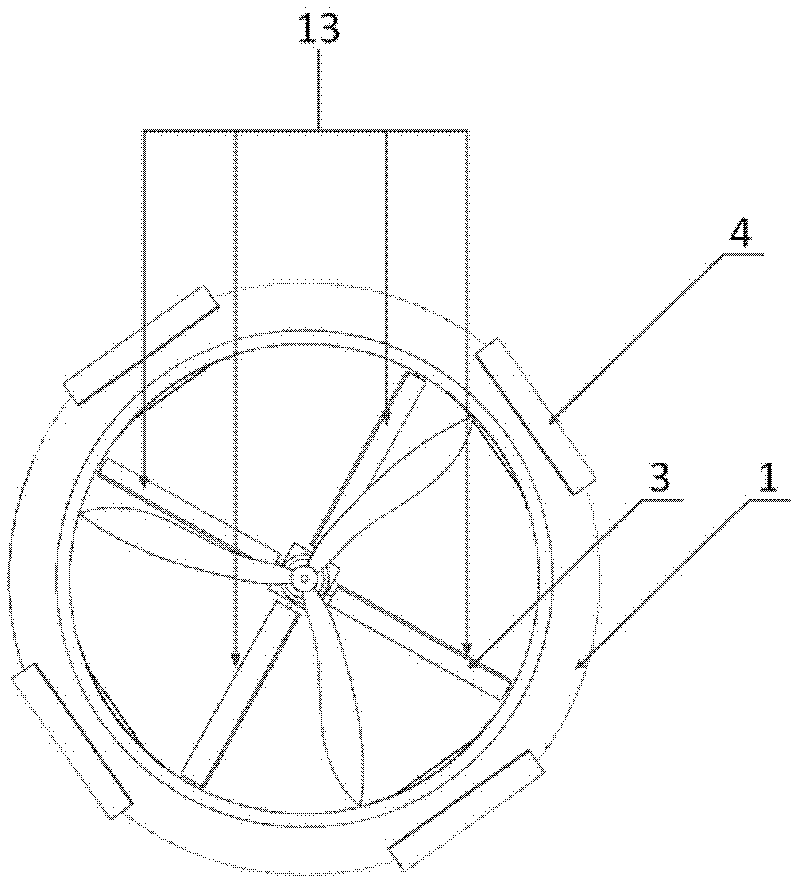

[0032] A saucer-shaped aircraft, comprising: a brushless DC motor 5, a propeller 2, a steering gear 12, a battery 7, a guide vane group 13 including a guide vane 3, and a duct body 1; the propeller 2 is fixed on the brushless DC motor 5 superior,

[0033] It is characterized in that it also includes a fixed block 6, the brushless DC motor 5 is connected to the upper surface of the fixed block 6, one end of the guide vane 3 is connected to the fixed block 6, and the other end is connected to the inner surface of the duct body 1, and the lower surface of the fixed block 6 is fixed There is a battery 7; it also includes a direction control rudder 4 and a control rudder connecting frame 8;

[0034] The direction control rudder 4 is formed by bending a rectangular plate into an arc along the direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com