Devices in a printing couple of a printing machine

A technology for printing devices and printing machines, which is applied to printing machines, general parts of printing machinery, rotary printing machines, etc., can solve problems such as shaft couplings that have not been elaborated, achieve belt replacement and maintenance simplification, save materials, and simplify construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

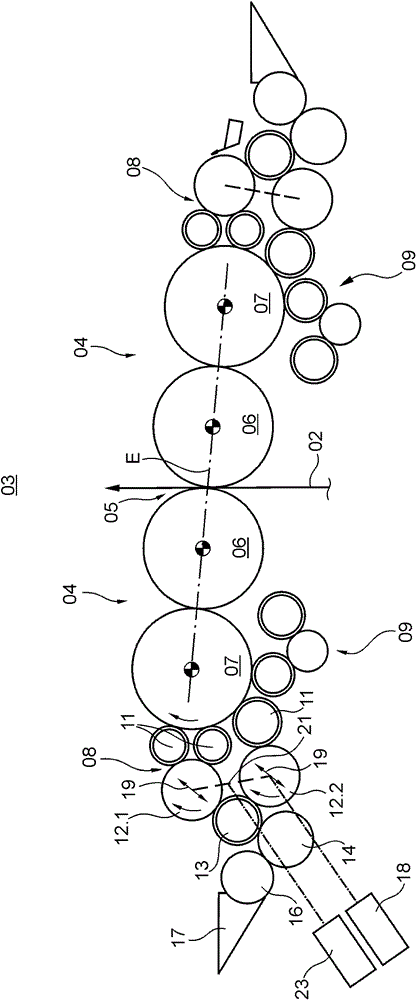

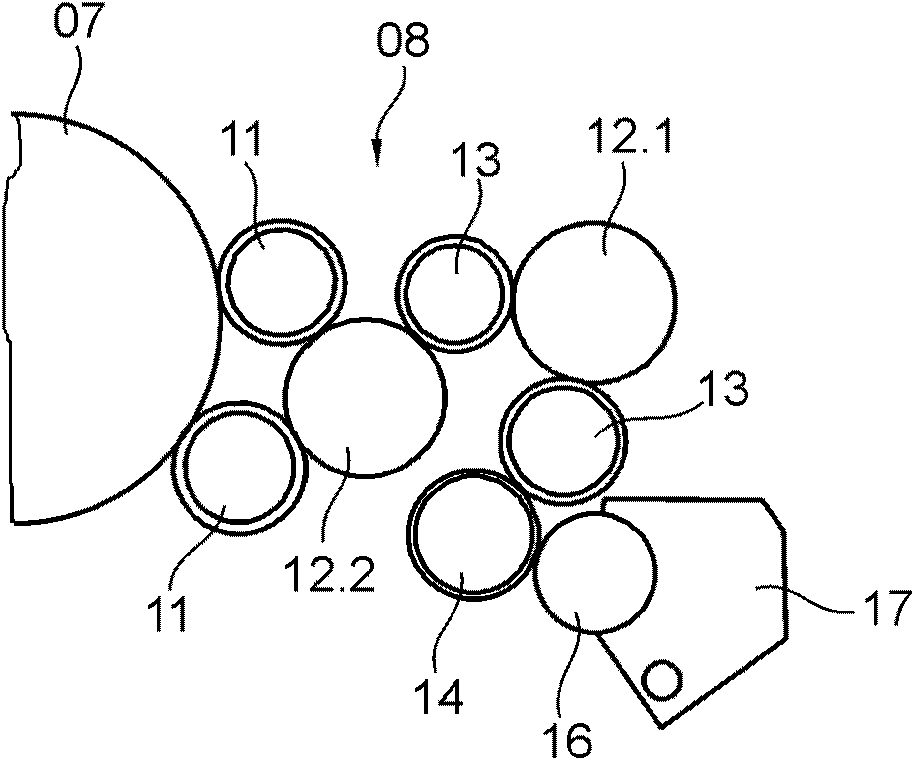

[0038] A printing press, such as a web rotary printing press, in particular a multicolor web rotary printing press, has at least one printing unit 01 in which double-sided single (einfach) or in particular sequential (mehrfach) multiple (mehrfach) ), such as quadruple printing a material belt 02, referred to as belt 02, or printing multiple belts 02 in single or multiple times at the same time.

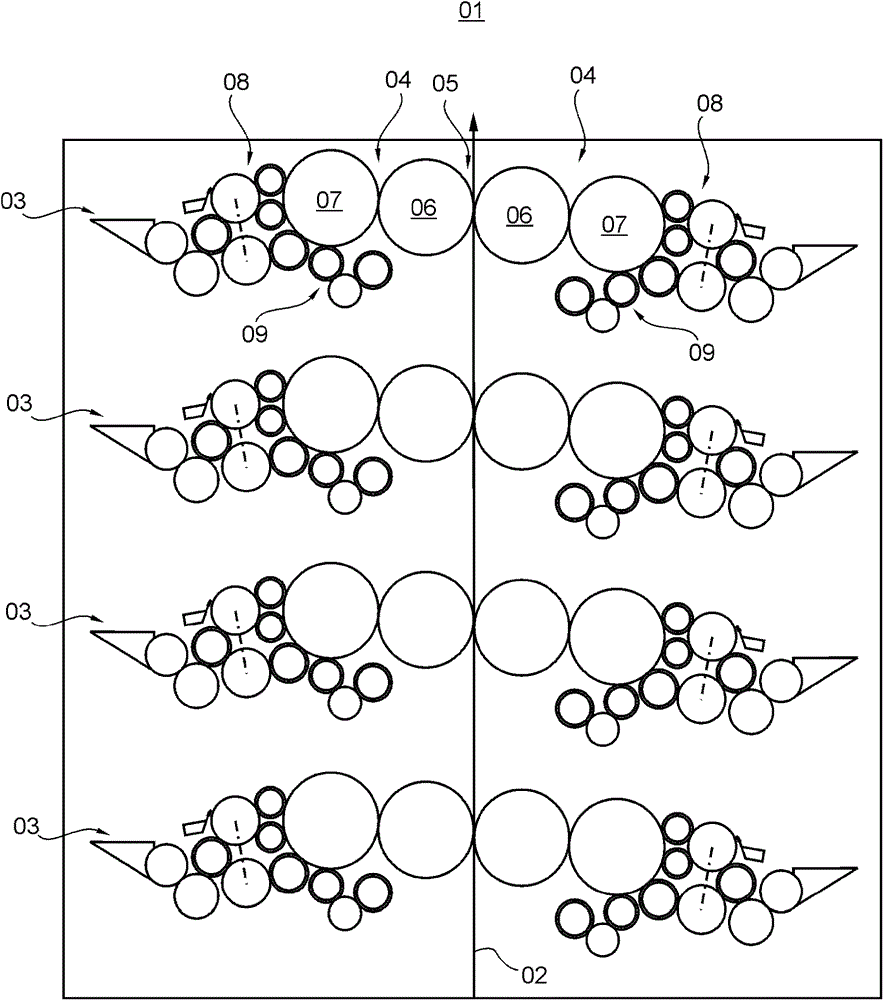

[0039] exist figure 1The printing unit 01 shown in is designed in the form of a printing tower with a substantially vertical rail run and has a plurality, in the present case 4, of double printing units 03 arranged vertically one above the other for printing on the rubber- Double-sided printing in rubber production (Gummi-Gegen-Gummi-Betrieb). Such a printing unit 01 designed in the form of a printing tower with a track running through the printing unit 01 from bottom to top is preferably arranged in a newspaper printing machine, wherein the newspaper printing machine has, for exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com