Ferromagnetic object demagnetizing method

A kind of object and ferromagnetic technology, applied in the field of demagnetization of ferromagnetic objects, can solve the problems of time-consuming and laborious, and achieve the effect of reducing labor intensity, easy maneuvering, and good demagnetization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

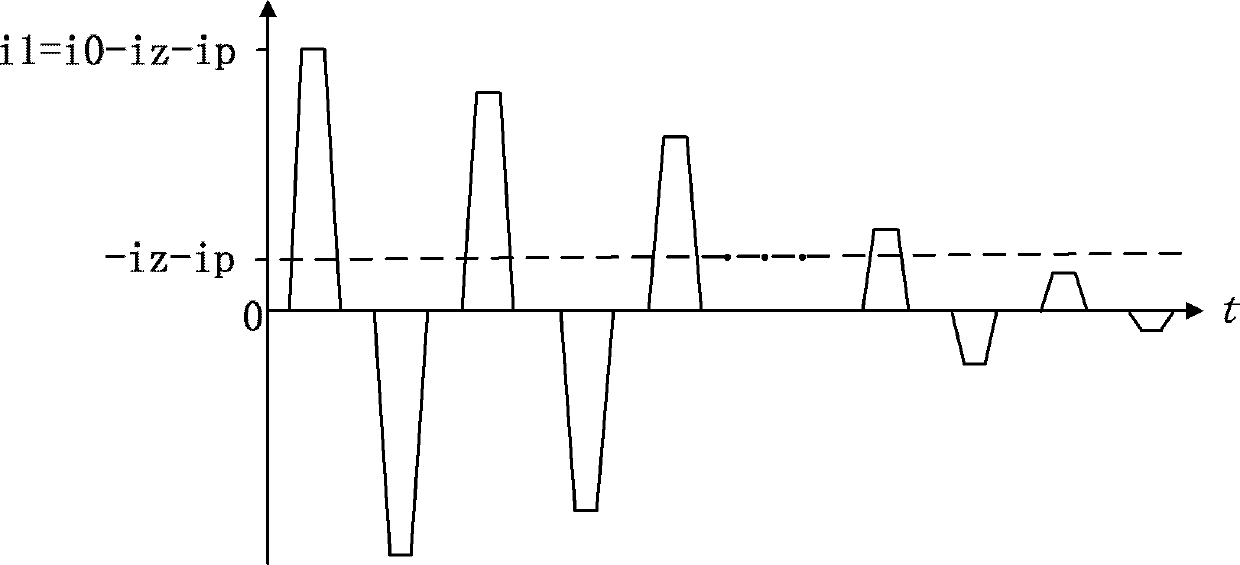

[0024] Embodiment 1, a 2-ton ferromagnetic ship, width b=1m, height h=1m, the vertical component Hz=20A / m of the local geomagnetic field, Hp=30A / m, realize overall demagnetization, include the following step:

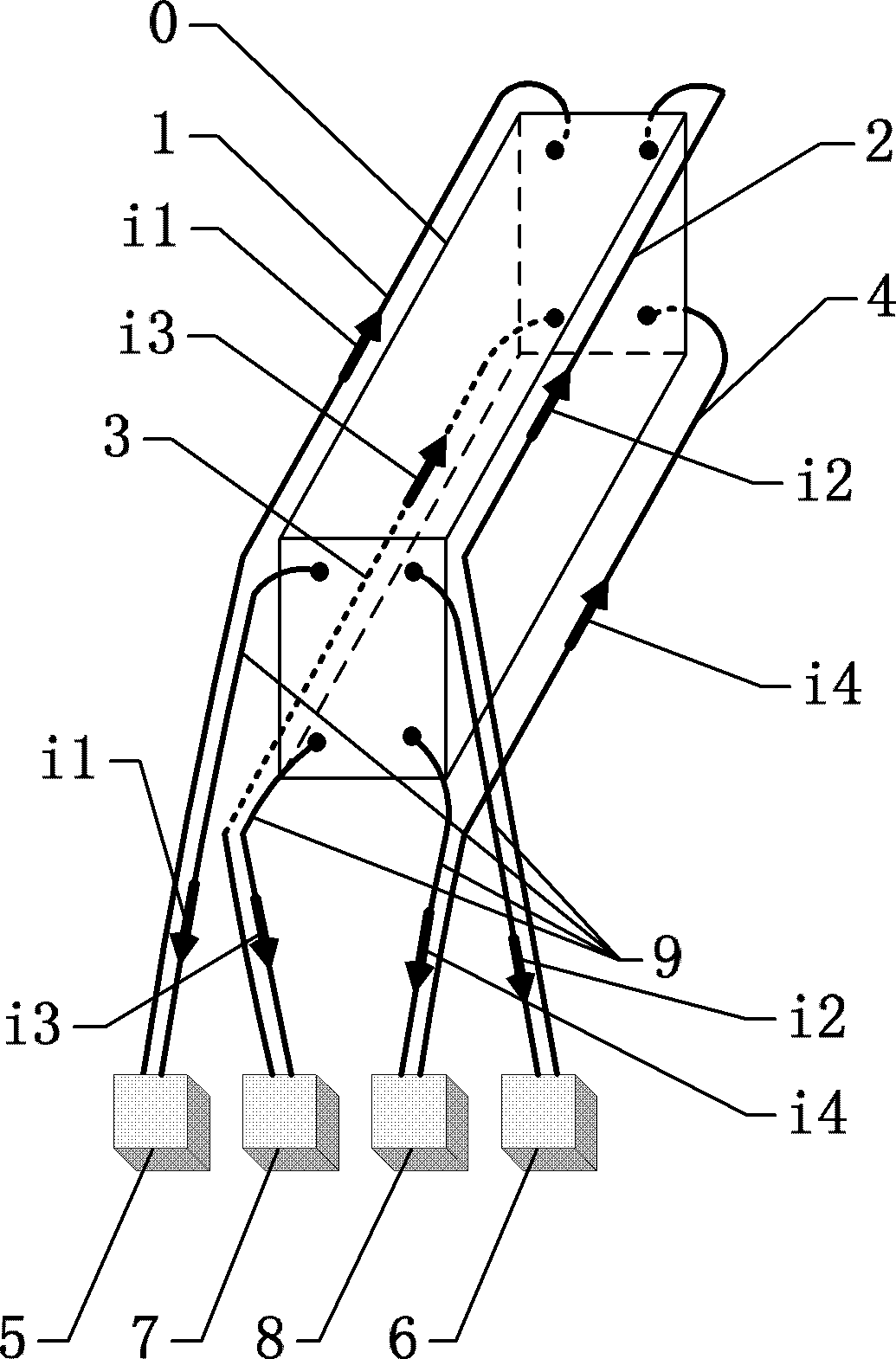

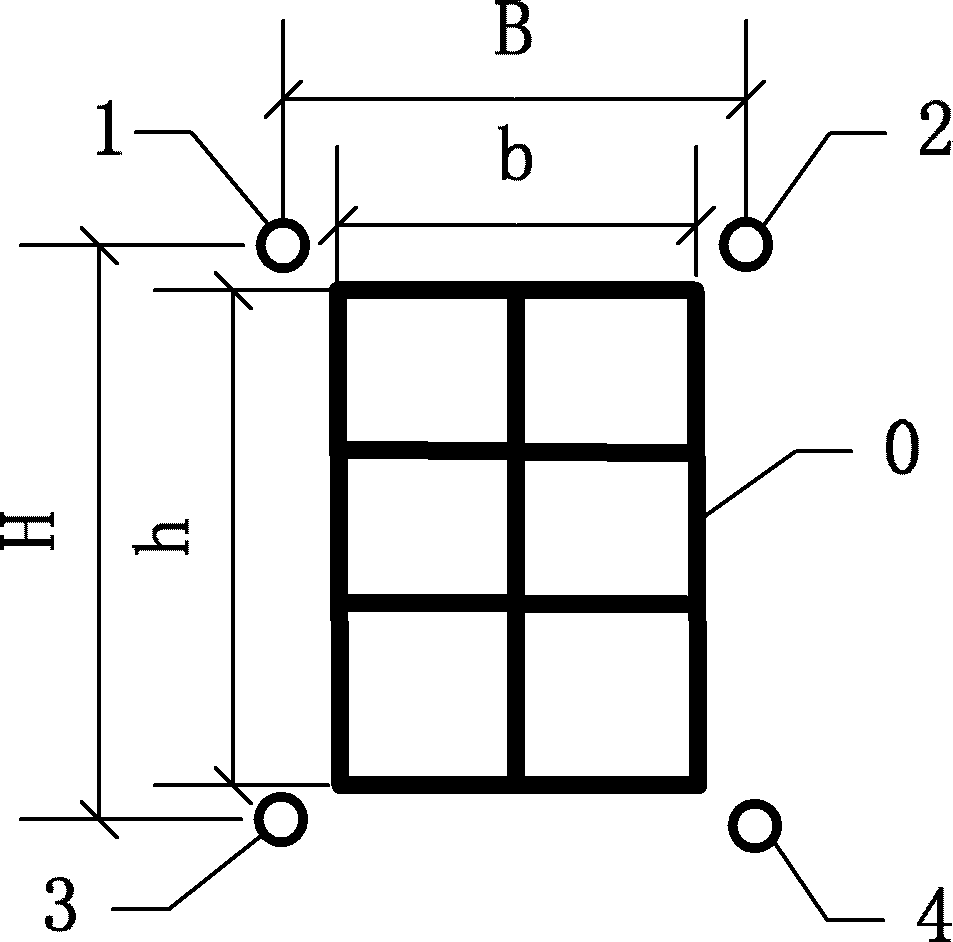

[0025] (1) Steps for laying cables: such as figure 1 , figure 2 As shown, a ferromagnetic object with a width of b=1m and a height of h=1m is placed in the east-west direction of the geomagnetism along its axial direction, and the first to fourth pulse power sources are placed at the head of the ferromagnetic object, and the first to fourth One pole of the pulse power supply is respectively connected to the head end surface of the ferromagnetic object through cables, and the other poles of the first to fourth pulse power supplies are respectively connected to the tail end surface of the ferromagnetic object through the first to fourth cables. The two cables are respectively located on the upper left side and the upper right side of the ferromagnetic object along the ...

Embodiment 2

[0030] Embodiment 2, a 1800-ton ferromagnetic ship, width b=10m, height h=10m, the vertical component Hz=30A / m of the local geomagnetic field, Hp=20A / m, realize overall demagnetization, including the following step:

[0031] (1) Steps for laying cables: such as figure 1 , figure 2 As shown, a ferromagnetic object with a width of b=10m and a height of h=10m is placed in the geomagnetic east-west direction along its axial direction, and the first to fourth pulse power sources are placed at the head of the ferromagnetic object, and the first to fourth One pole of the pulse power supply is respectively connected to the head end surface of the ferromagnetic object through cables, and the other poles of the first to fourth pulse power supplies are respectively connected to the tail end surface of the ferromagnetic object through the first to fourth cables. The two cables are respectively located on the upper left side and the upper right side of the ferromagnetic object along the...

Embodiment 3

[0037] Embodiment 3, a 20,000-ton ferromagnetic ship, width b=20m, height h=20m, the vertical component Hz=30A / m of the local geomagnetic field, Hp=20A / m, realize overall demagnetization, including the following step:

[0038] (1) Steps for laying cables: figure 1 , figure 2 As shown, place a ferromagnetic object with a width of b=20m and a height of h=20m along its axial direction in the geomagnetic east-west direction, place the first to fourth pulse power sources at the head of the ferromagnetic object, and place the first to fourth One pole of the pulse power supply is respectively connected to the head end surface of the ferromagnetic object through cables, and the other poles of the first to fourth pulse power supplies are respectively connected to the tail end surface of the ferromagnetic object through the first to fourth cables. The two cables are respectively located on the upper left side and the upper right side of the ferromagnetic object along the axial direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com