Automatic detection method of optical fiber fusion quality

An optical fiber fusion splicing and automatic detection technology, which is used in the coupling of optical waveguides, instruments, characters and pattern recognition, etc., can solve the problems of difficult to meet the requirements of optical fiber fusion image recognition, low resolution of fusion images, and high cost of algorithm operation time. Dependence on anti-noise ability, simplify tedious steps, and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

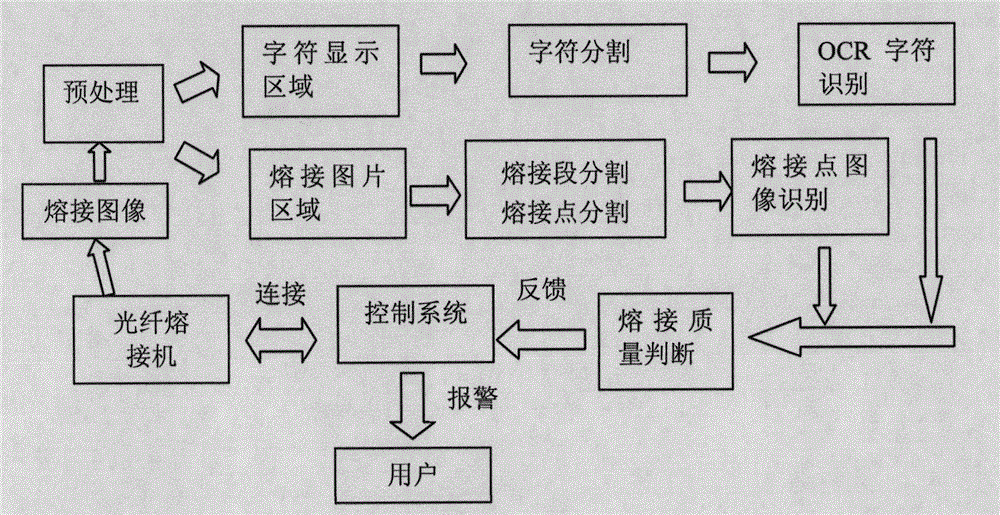

[0043] Such as figure 1 As shown, the automatic detection process of optical fiber splicing quality mainly includes the following steps:

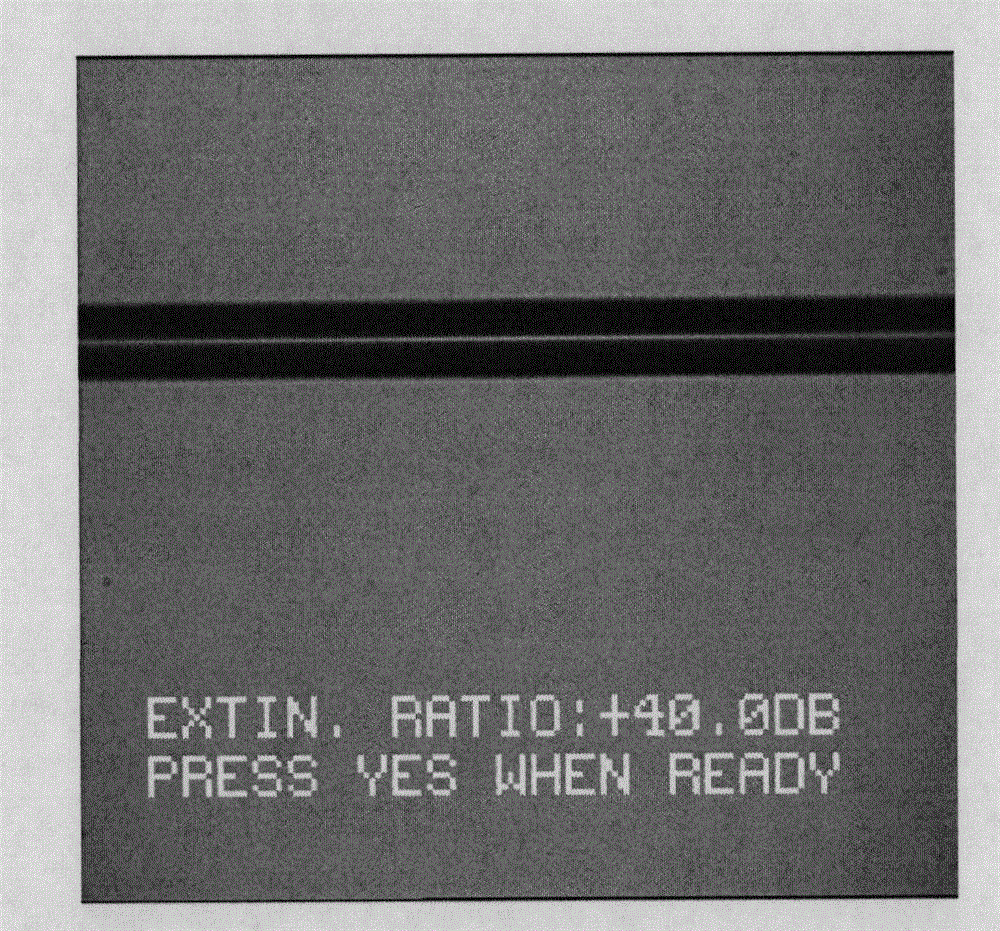

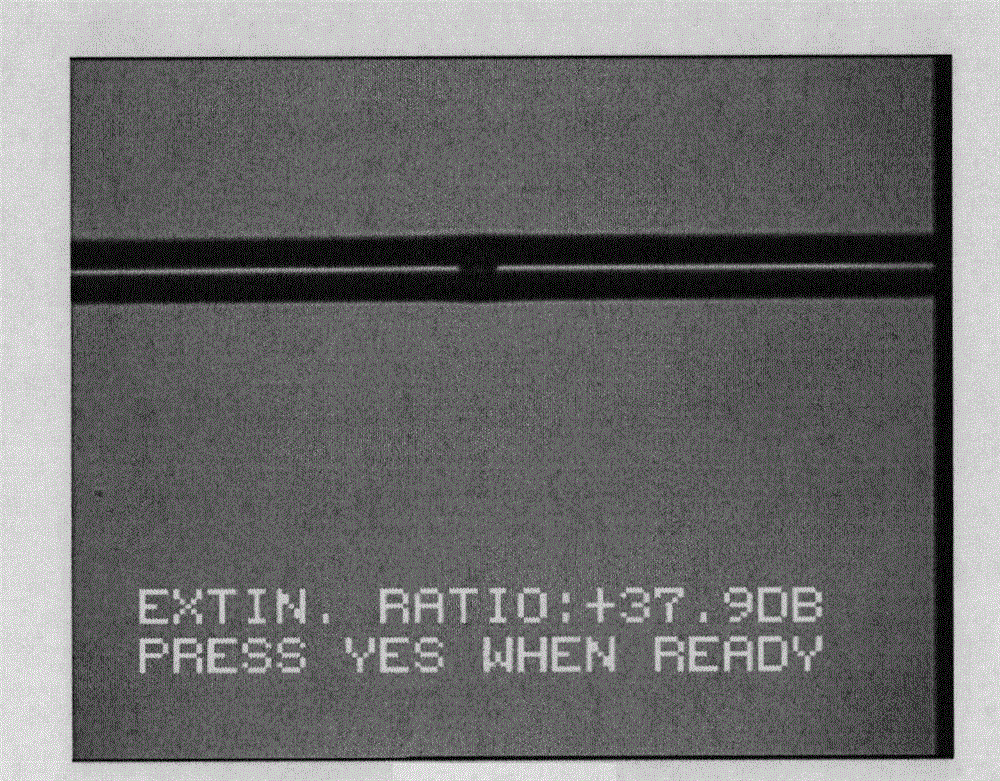

[0044] (1) Connect the optical fiber fusion splicer with the control system, and use the optical fiber fusion splicer to perform the fusion splicing operation of the optical fiber. The control system is used to control the opening and closing of the optical fiber fusion splicer and perform fault alarm. The steps of the fiber fusion splicing machine are mainly divided into 4 processes, which generate 7 key parameters related to the quality of the fusion splicing, and a set of partial images of the splicing point that can be rotated 360 degrees. This set of images can show whether there are bubbles in the splicing point, etc. defect. The first process of optical fiber fusion is the arc cleaning process, which removes the q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com