Checking fixture for measuring depth of bottom hole of valve retainer of engine cylinder cover

A technology of engine cylinder head and valve seat ring, which is applied in the field of measurement and inspection tools, can solve the problems of large measurement error, corrosion of measuring rod, short service life, etc., and achieve the effects of accurate and reliable measurement data, smooth and soft movement, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

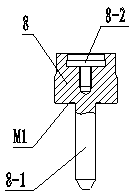

[0024] See Figure 1, image 3 , Figure 5 The composition of the present invention includes a measurement actuator, a displacement transmission mechanism, a support and control mechanism, and a measurement data display mechanism. The measurement actuator includes a guide rod 8, a flange seat 7 and a flange cover 6. The guide rod 8 is located at the lower end of the inspection tool, and consists of two parts: the probe 8-1 and the connecting seat 8-2. The bottom surface of the connecting seat 8-2 is the test reference plane M1, and the top is fixedly connected with the bottom of the measuring rod seat 5. The flange The seat 7 is an inverted disc structure, the top surface is provided with a large round hole, the bottom surface is the measuring surface M2, and the flange cover 6 is fixedly installed on the top surface of the flange seat 7, and the center of the flange cover 6 is provided with a disc-shaped groove 6 -2, the disc-shaped groove 6-2 is connected to the peripheral f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com