Device used for preventing flue gas at outlet of chimney from carrying droplets after wet desulphurization

A technology of chimney outlet and wet desulfurization, which is applied to exhaust gas devices, combustion methods, and treatment of combustion products, can solve the problems of increasing pollutant emissions, affecting the safety of chimneys, and insufficient design understanding, so as to achieve good social benefits and Economic benefits, reduced cleaning and maintenance workload, and the effect of avoiding droplet carrying phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

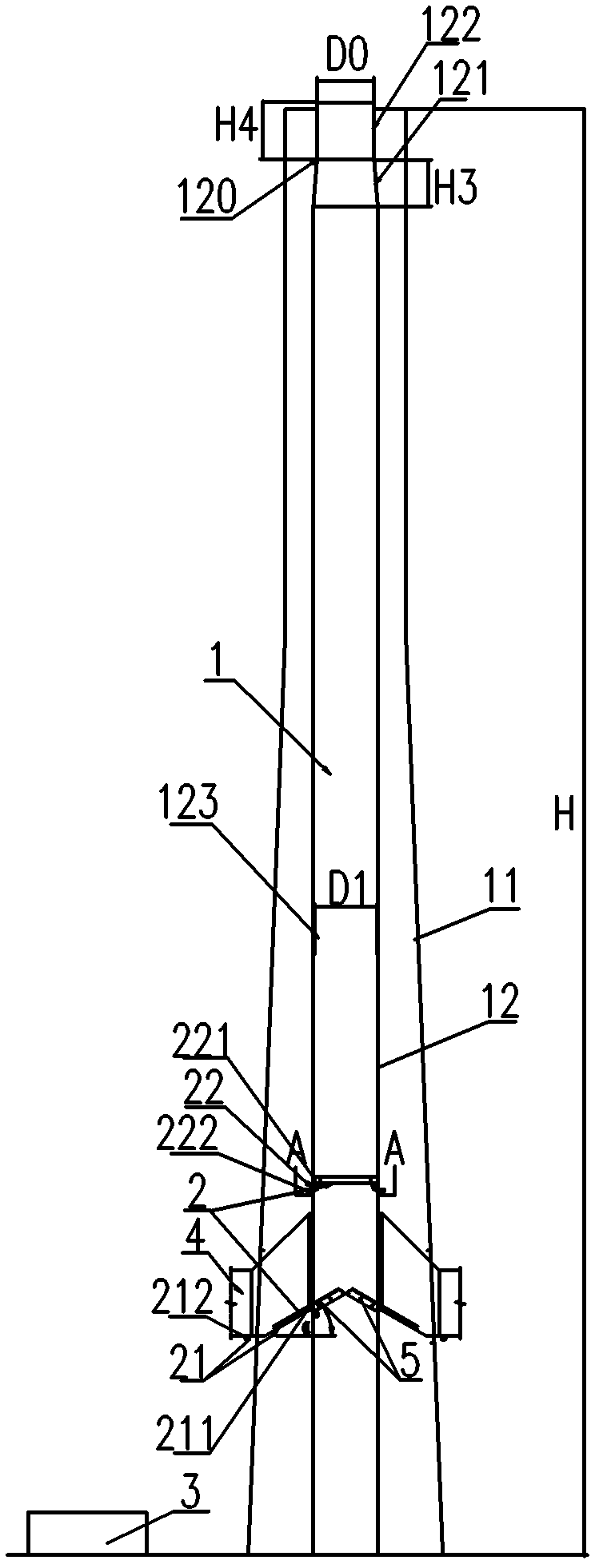

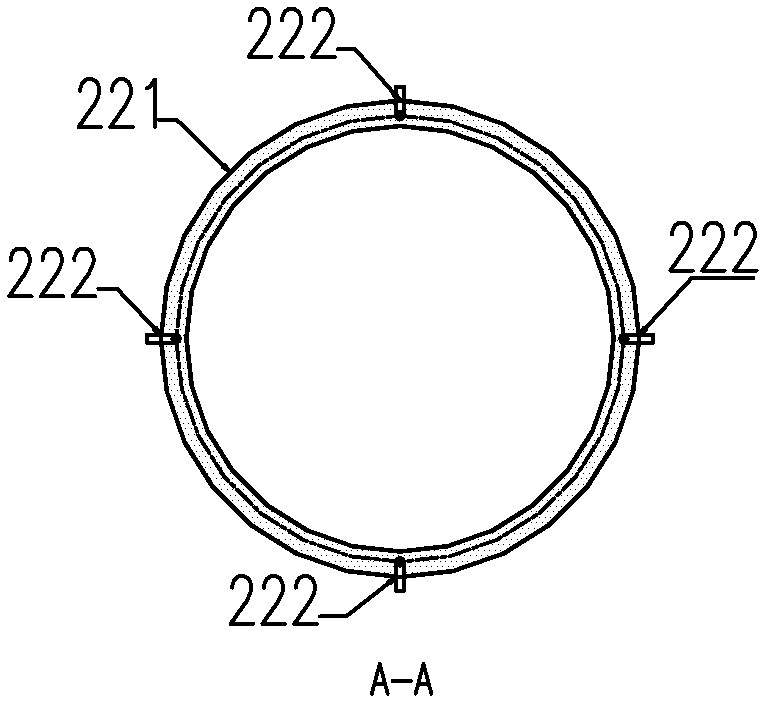

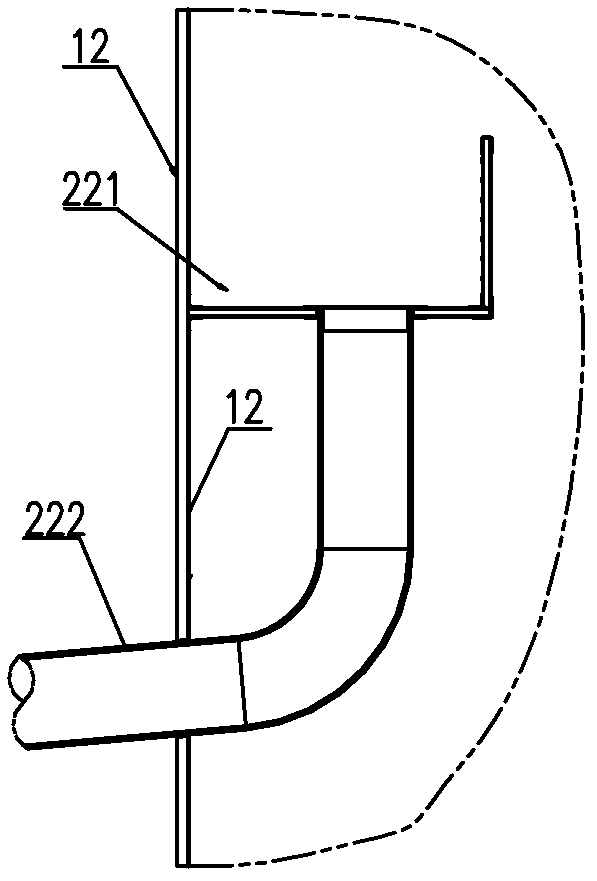

[0026] The anti-flue gas droplet carrying device at the chimney outlet after wet desulfurization shown in the figure includes a casing chimney 1 and a main flue 4. The casing chimney 1 includes a chimney outer cylinder 11 and a chimney inner cylinder 12. In the casing chimney 1 A droplet recovery device 2 is provided inside. The droplet recovery device 2 includes a first-stage acid liquid discharge device 21 and a second-stage acid liquid discharge device 22 . An anti-clogging cleaning device 5 is also provided under the droplet recovery device 2 .

[0027] The chimney inner cylinder 12 is sleeved in the chimney outer cylinder 11, the chimney inner cylinder 12 includes an outlet section 120 and a lower smoke exhaust pipe 123, the outlet section 120 includes an outlet contraction section 121 and an outlet straight section 122, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com