Diesel engine oil injector hold-down device

A technology of pressing device and fuel injector, which is applied in the direction of fuel injection device, machine/engine, charging system, etc., can solve problems such as difficult arrangement of briquetting support points, failure of cylinder head arrangement scheme, etc., and achieves simple structure, Effect of compact design and reduced camshaft pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

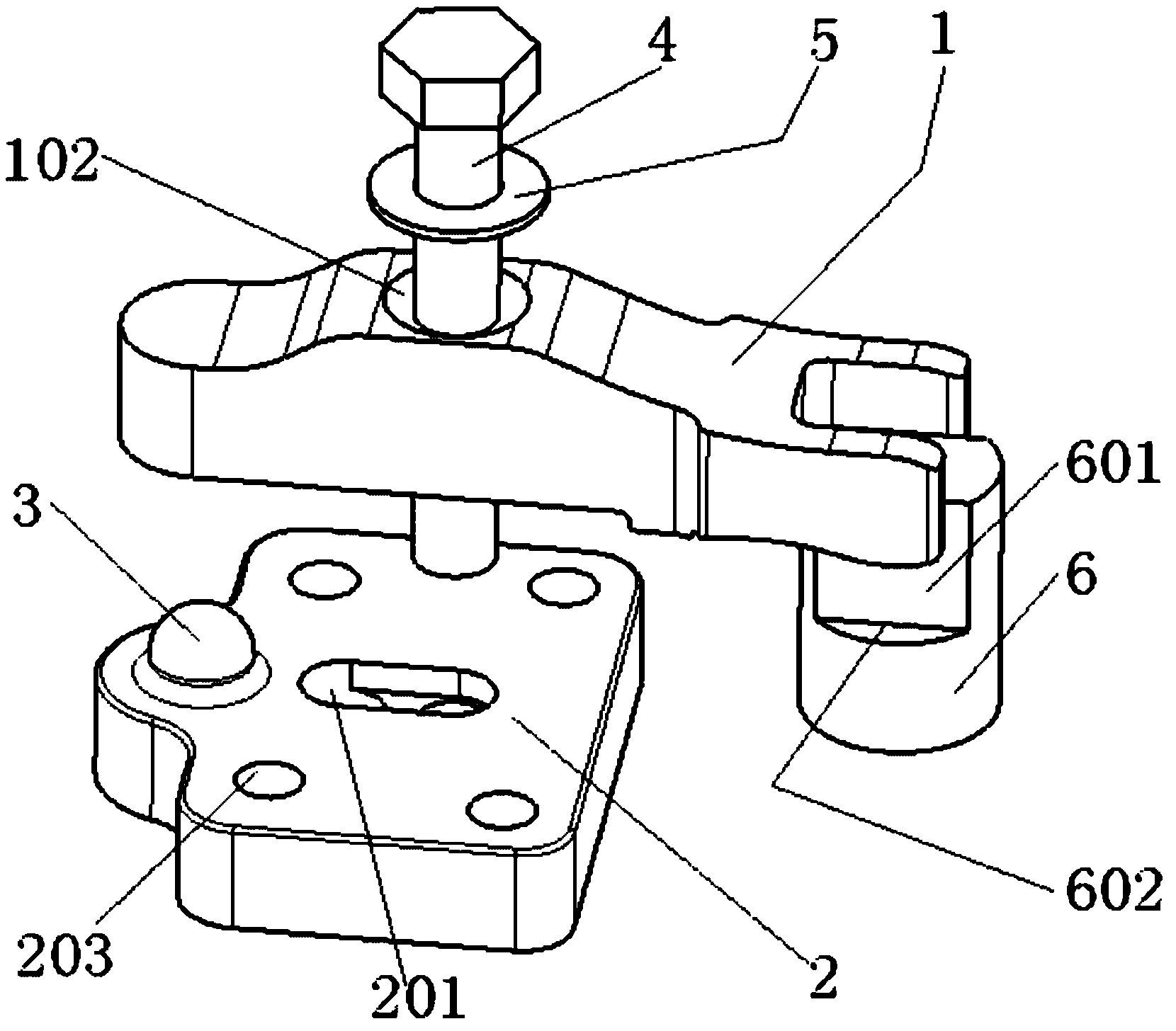

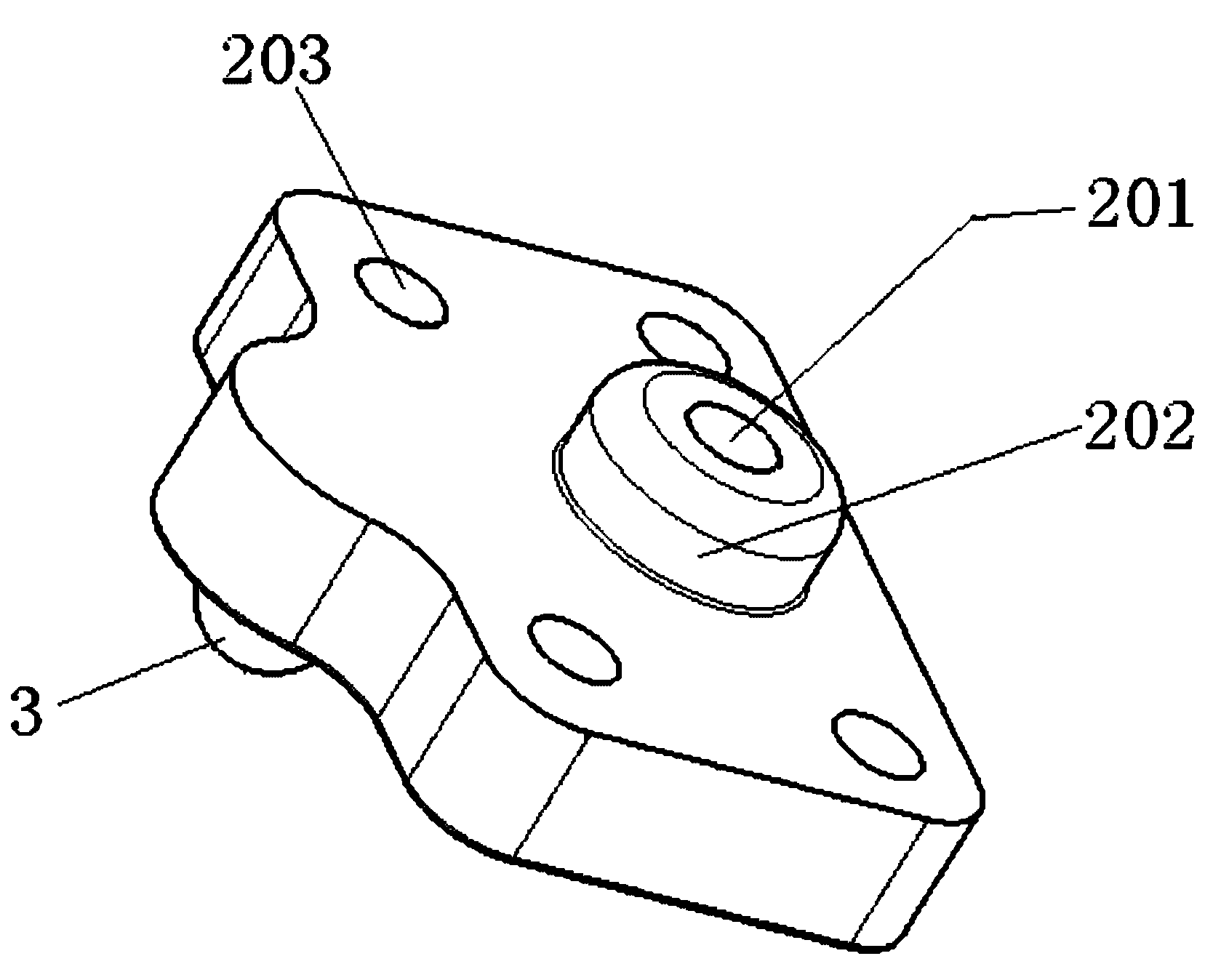

[0016] figure 1 It is a schematic structural diagram of the technical principle of the diesel injector pressing device. The diesel injector pressing device includes a pressing block 1, a support plate 2, a supporting ball head 3, a pressing block bolt 4 and a spherical washer 5.

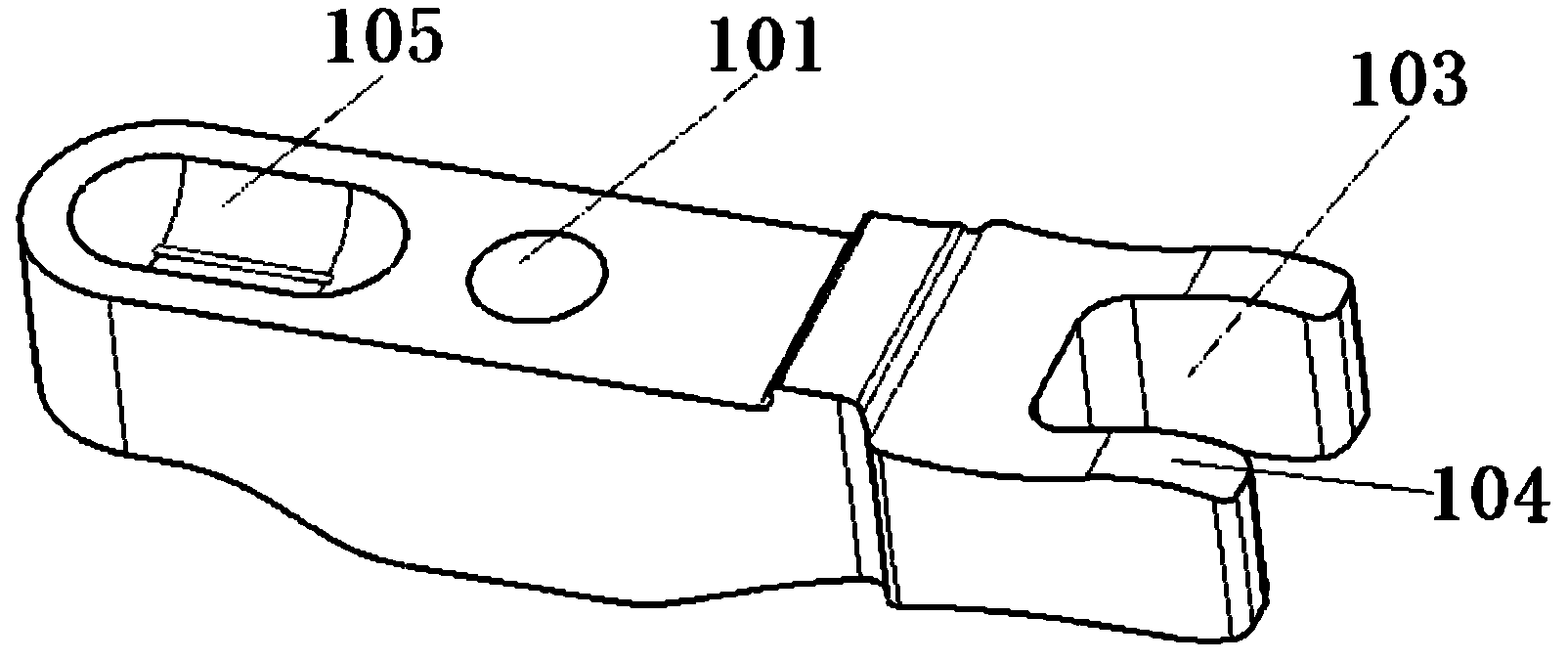

[0017] The middle part of the pressure block 1 has a bolt hole 101 passing through the top surface and the bottom surface, and the edge of the bolt hole 101 on the top surface is a tapered surface 102 . Such as figure 2 As shown, one end of the pressure block 1 is a clamping part, and the clamping part has a clamping part opening 103 whose width is the same as the thickness between the two injector facades 601 of the injector 6, and the injector clamp The bottom surface at the opening 103 of the holding part is an arc-shaped bottom surface 104 of the holding part, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com