Extensible building steel structure

A steel structure and construction technology, applied in building construction, construction, etc., can solve the problem of space forming that cannot be implemented in one step, and achieve the effect of facilitating the disassembly process, avoiding initial internal force, and saving construction time and construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of a scalable building steel structure of the present invention will be described in further detail below through embodiments in conjunction with the accompanying drawings.

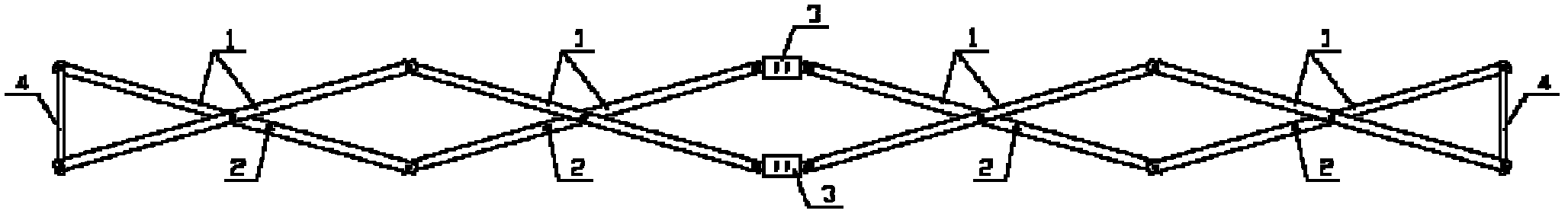

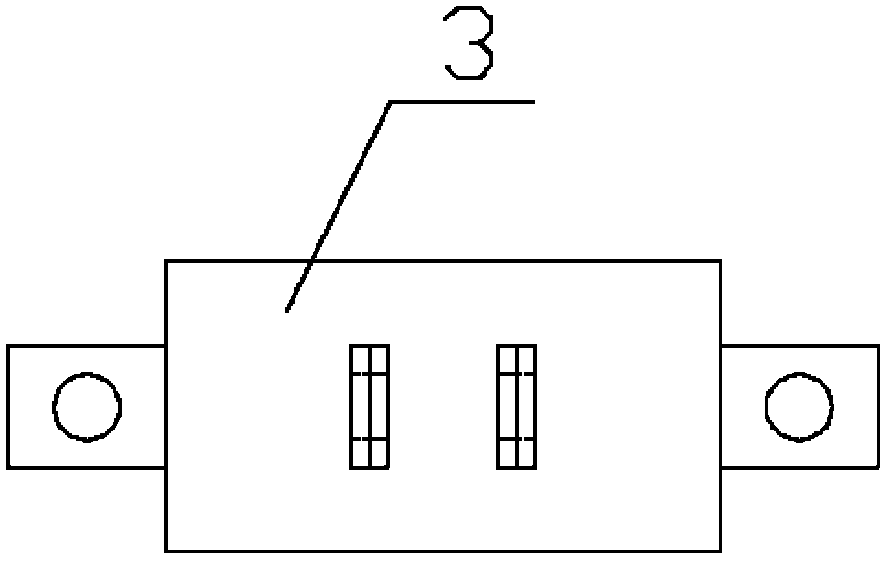

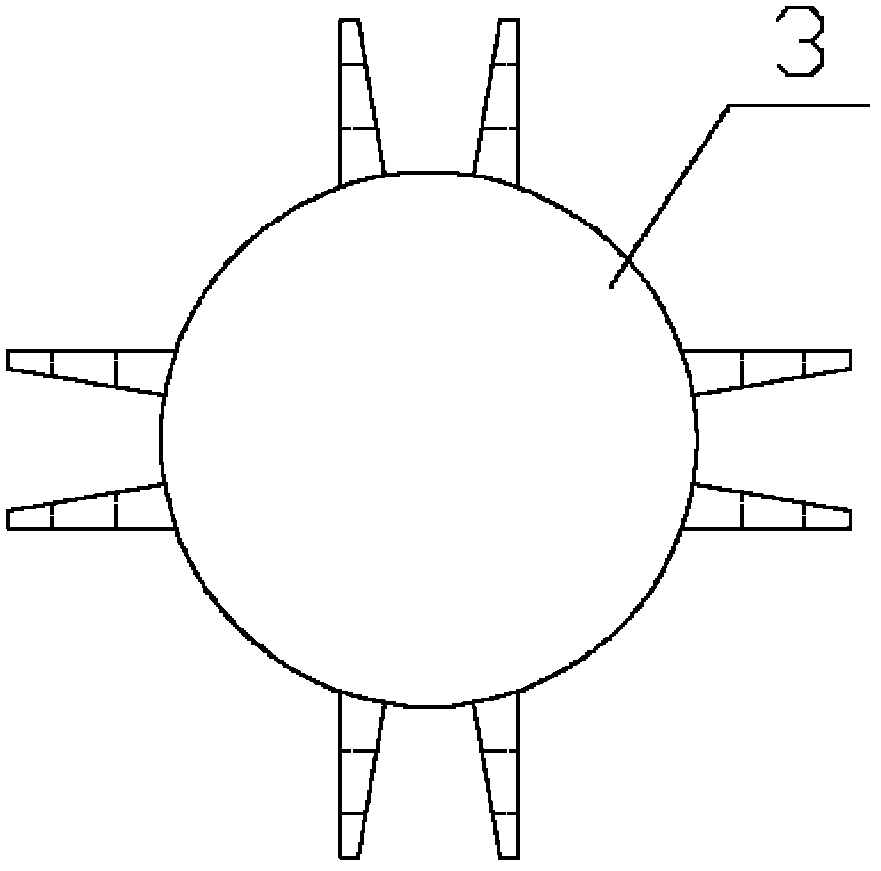

[0019] like Figure 1 to Figure 3 As shown, a scalable building steel structure is composed of an X-shaped component 1 , a limit block 2 , an intermediate connector 3 , and a tie rod 4 . Wherein the X-shaped member 1 is formed by connecting two slender rods in the middle through a pivot pin, and the two ends of the X-shaped member 1 are provided with holes for mutual connection, and the distance from the corresponding surface of the intermediate pivot pin is Weld a short cylindrical limit block 2; then connect two X-shaped components 1 to each other with pins, and connect an intermediate connector 3 between two X-shaped components 1; the intermediate connector 3 is a short cylinder X-shaped, four groups of two ear plates separated in parallel and with holes for connection ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com