Treatment method and cast structure for contact position of retaining wall with workshop column foundation

A technology of retaining wall foundation and treatment method, which is applied in the direction of basic structure engineering, underwater structures, buildings, etc., can solve the problems of main factory building displacement, difficult construction, and unclear force, so as to save raw materials and manufacture Low cost, reasonable and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

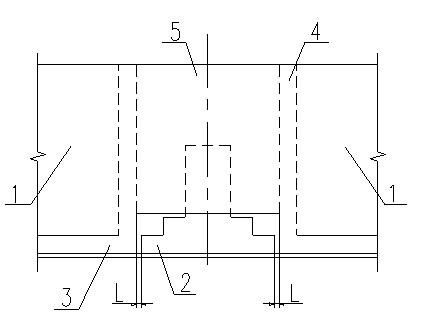

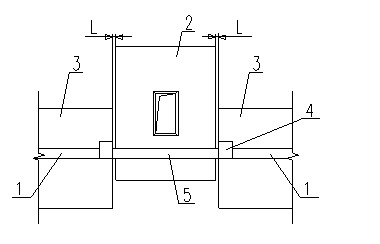

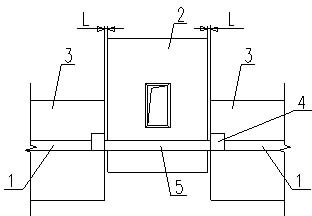

[0012] Embodiment of the present invention: when designing and constructing a factory building that needs to pour the retaining wall 1, the retaining wall 1 and the factory building column foundation 2 can be designed and constructed separately as two separate monomers with different structural forms. The design and construction method of the wall 1 and the single factory building column foundation 2 can directly adopt the existing technology and determine according to actual use needs. When the position of the set retaining wall 1 collides with the factory building column foundation 2, the The retaining wall foundation 3 of the pouring retaining wall 1 is canceled within the range of the factory building column foundation 2, and the distance L between the retaining wall foundation 3 poured on the outer sides of the factory building column foun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com