Black low-flow-mark polyester molding compound and preparation method thereof

A molding compound and black technology, which is applied in the field of polyester molding compound and its preparation, can solve the problems of whitening and blooming, and the inability to obtain uniform and uniform colored products, etc., and achieve the effect of long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

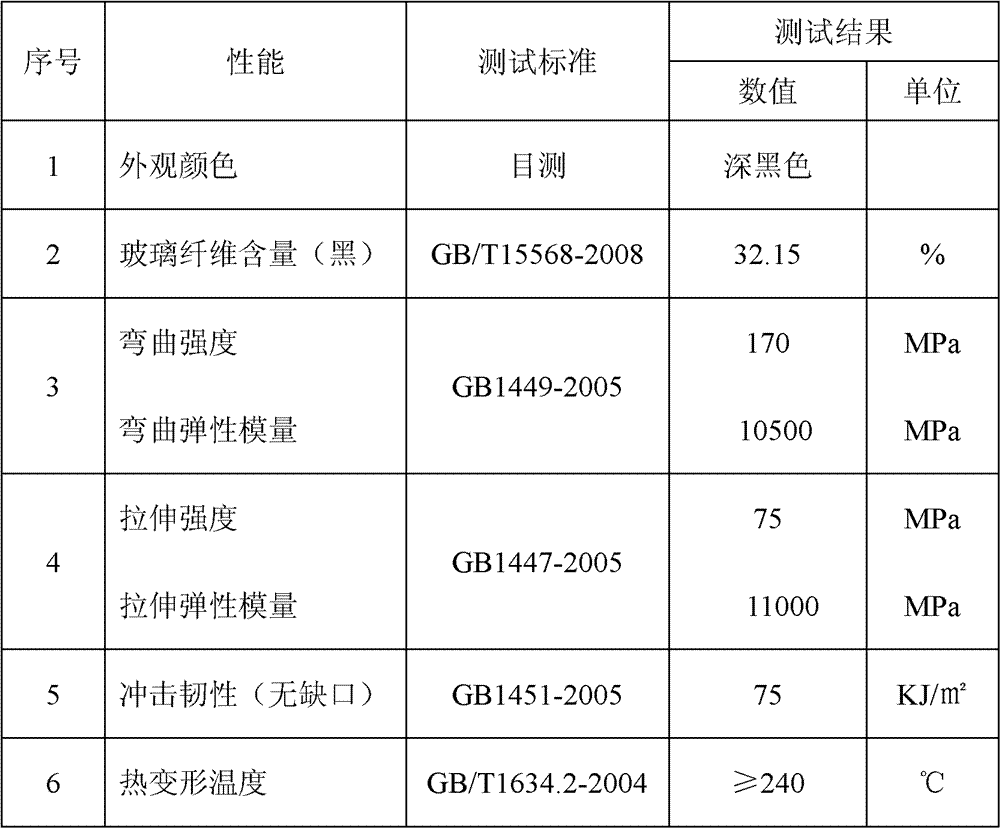

Embodiment 1

[0038] Black low-corrugation polyester molding compound, mixed with the following raw materials in weight percentage:

[0039] Resin paste 68%;

[0040] Alkali-free chopped glass fiber 32%;

[0041] The resin paste is composed of the following raw materials in parts by weight: 50 parts of ortho-phthalic unsaturated polyester resin, 50 parts of NP2000 from ASHLAND, USA, 1.2 parts of tert-butyl benzoyl peroxide, and 190 mesh zinc stearate powder 2 parts, 150 parts of 300 mesh calcium carbonate, 0.8 parts of magnesium oxide.

[0042] The method for preparing the black low-corrugation polyester molding compound includes the following steps in sequence:

[0043] (1) Weigh the o-phthalic unsaturated polyester resin and the NP2000 of Ashland Company in the United States according to the weight of the formula, pour it into the bucket, and stir at 1000 rpm for 4-5 minutes at high speed

[0044] (2) Add formula amount of tert-butyl benzoyl peroxide and 2 parts of 190 mesh zinc stearate powder, an...

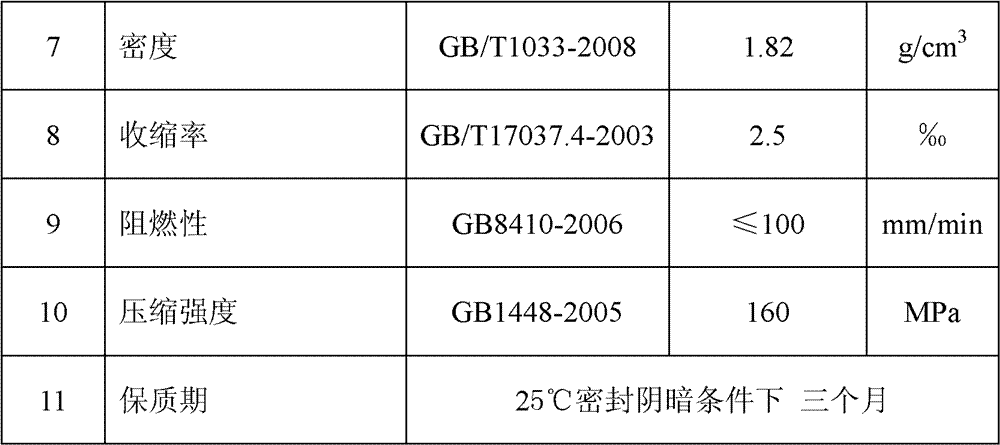

Embodiment 2

[0052] Black low-corrugation polyester molding compound, mixed with the following raw materials in weight percentage:

[0053] Resin paste 73%;

[0054] Alkali-free chopped glass fiber 27%;

[0055] The resin paste is composed of the following raw materials in parts by weight: 65 parts of isophthalic unsaturated polyester resin, 35 parts of NP2000 from ASHLAND, USA, 1.5 parts of tert-butyl benzoyl peroxide, and 200 mesh zinc stearate powder 2 parts, 5 parts of styrene, 200 parts of 400 mesh calcium carbonate, 0.8 parts of magnesium oxide.

[0056] The method for preparing the black low-corrugation polyester molding compound includes the following steps in sequence:

[0057] (1) Weigh the isophthalic unsaturated polyester resin and the NP2000 of Ashland Company of the United States according to the weight of the formula, pour into the bucket, and stir at 1000 rpm for 4-5 minutes at high speed

[0058] (2) Add formula amount of tert-butyl benzoyl peroxide, styrene, and 200 mesh zinc stear...

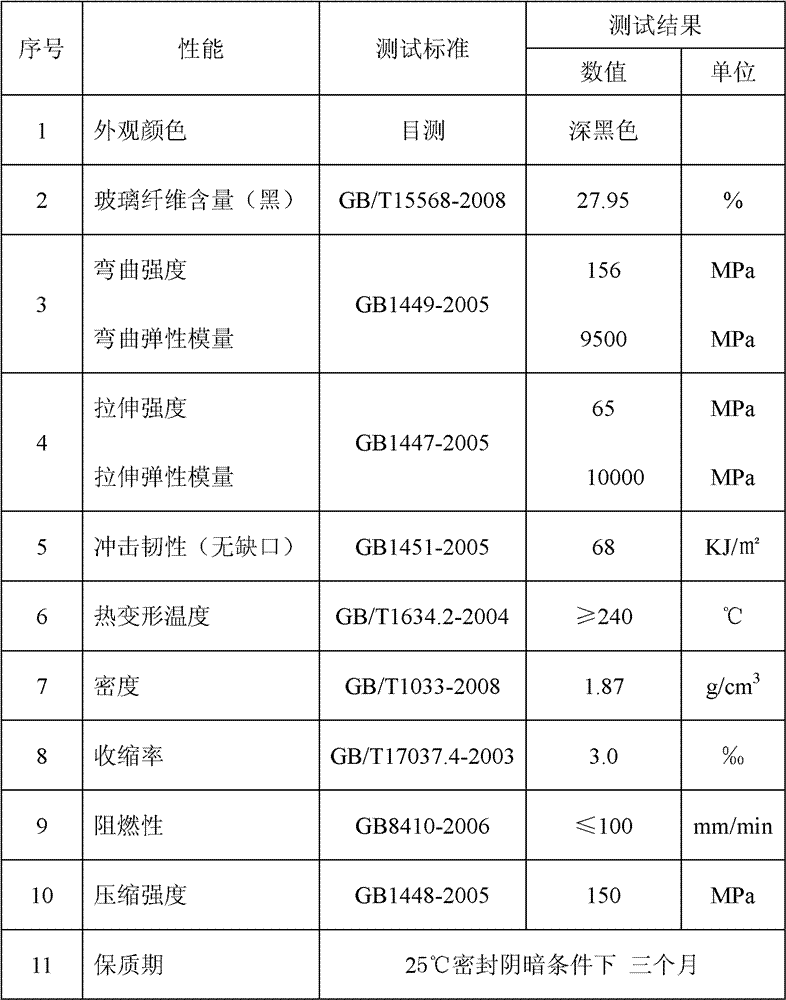

Embodiment 3

[0065] Black low-corrugation polyester molding compound, mixed with the following raw materials in weight percentage:

[0066] Resin paste 78%;

[0067] Alkali-free chopped glass fiber 22%;

[0068] The resin paste is composed of the following raw materials in parts by weight: 65 parts of vinyl unsaturated polyester resin, 35 parts of NP2000 from ASHLAND, USA, 1.5 parts of tert-butyl benzoyl peroxide, and 210 mesh zinc stearate powder 4 parts, 5 parts of styrene, 200 parts of 500 mesh calcium carbonate, 0.8 parts of magnesium oxide.

[0069] The method for preparing the black low-corrugation polyester molding compound includes the following steps in sequence:

[0070] (1) Weigh the ethylenically unsaturated polyester resin and the NP2000 of Ashland Company in the United States according to the weight of the formula, pour into the bucket, and stir at 1000 rpm for 4-5 minutes at high speed

[0071] (2) Add formula amount of tert-butyl benzoyl peroxide, styrene, 210 mesh zinc stearate powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com