Turnout forging and pressing die

A technology for forging and turnout, which is applied in the field of forging die for railway turnout, which can solve the problems of low efficiency, large lateral force and economic loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

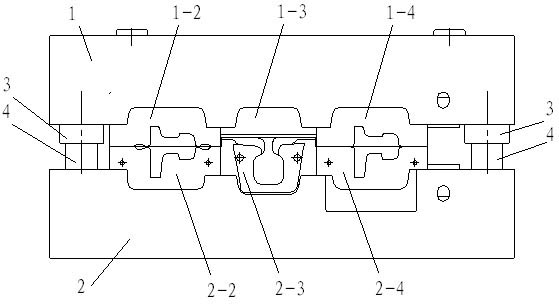

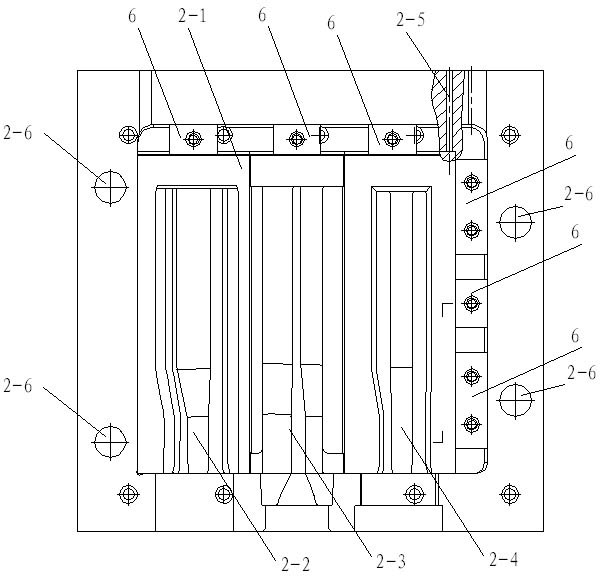

[0025] see figure 1 , 2 , 3, and 4 shown, a turnout forging die, including the upper mold frame 1 and the lower mold frame 2, the upper mold frame 1 and the lower mold frame 2 are fastened by the guide sleeve 3 and the guide post 4, and the upper mold frame 1 has The upper mold sinking cavity 1-1, the upper mold sinking cavity 1-1 has an upper module 1-4, the lower mold frame 2 has a lower mold sinking cavity 2-1, and the lower mold sinking cavity 2-1 has a lower module 2- 4. After the upper mold frame 1 and the lower mold frame 2 are fastened together, the upper module 1-4 corresponds to the lower module 2-4, and the lower mold frame 2 has a drainage hole 2-1 connected with the lower mold cavity 2-1. 5. There is also a module disassembly auxiliary device 5 and a module fastening device 6 between one end of the upper module 1-4 and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com