Iron core structure of transformer

A technology of iron core structure and transformer, applied in the direction of transformer/inductor magnetic core, transformer/inductor parts, electrical components, etc., can solve the problem of weak assembly of coil and iron core, slow assembly speed of transformer iron core, electromagnetic eddy current Large loss and other problems, to achieve the effect of solving eddy current loss, preventing magnetic saturation, and reducing chassis resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

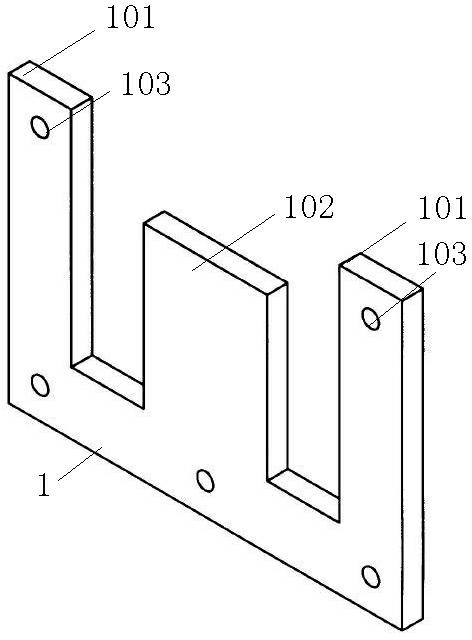

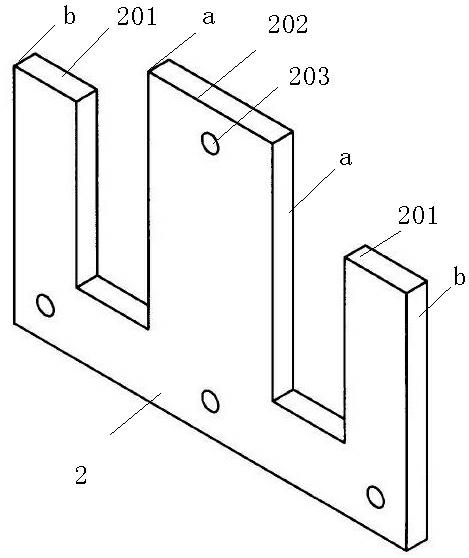

[0019] Such as figure 1 as shown, figure 2 As shown, the overall height of the first E-type piece 1 and the second E-type piece 2 of the iron core structure of the transformer is consistent, and the outer magnetic column 101 of the first E-type piece 1 is higher than that of the second E-type piece 2 Outer magnetic column 201, the middle magnetic column 102 of the first E-type sheet 1 is lower than the middle magnetic column 202 of the second E-type sheet 2, and the outer magnetic column 101 of the first E-type sheet 1 and the second E-type sheet 2 Middle magnetic post 202 is high, and the middle magnetic post 102 of the first E-type sheet 1 is equal to the outer magnetic post 201 of the second E-type sheet 2; There is a group of connection holes, a connection hole 103 is provided on the outer magnetic column 101 of the first E-shaped sheet 1 , and a connection hole 203 is provided on the middle magnetic column 202 of the second E-shaped sheet 2 .

[0020] Such as image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com