Elastic coupling for motor

A technology for elastic couplings and motor shafts, which is applied in the direction of elastic couplings, couplings, electrical components, etc., to achieve the effects of simple structure, increased ability to transmit torque, and convenient wearing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

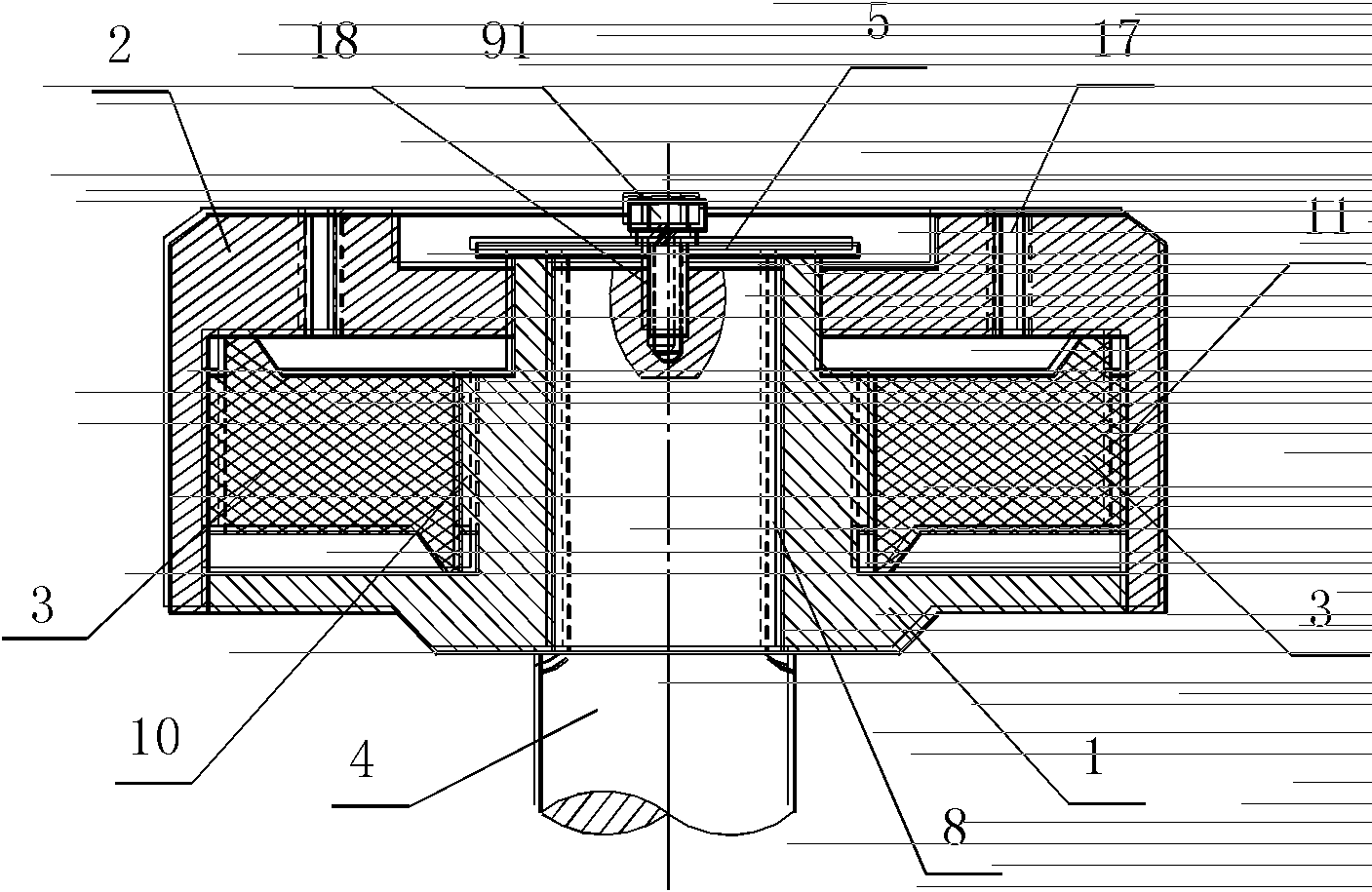

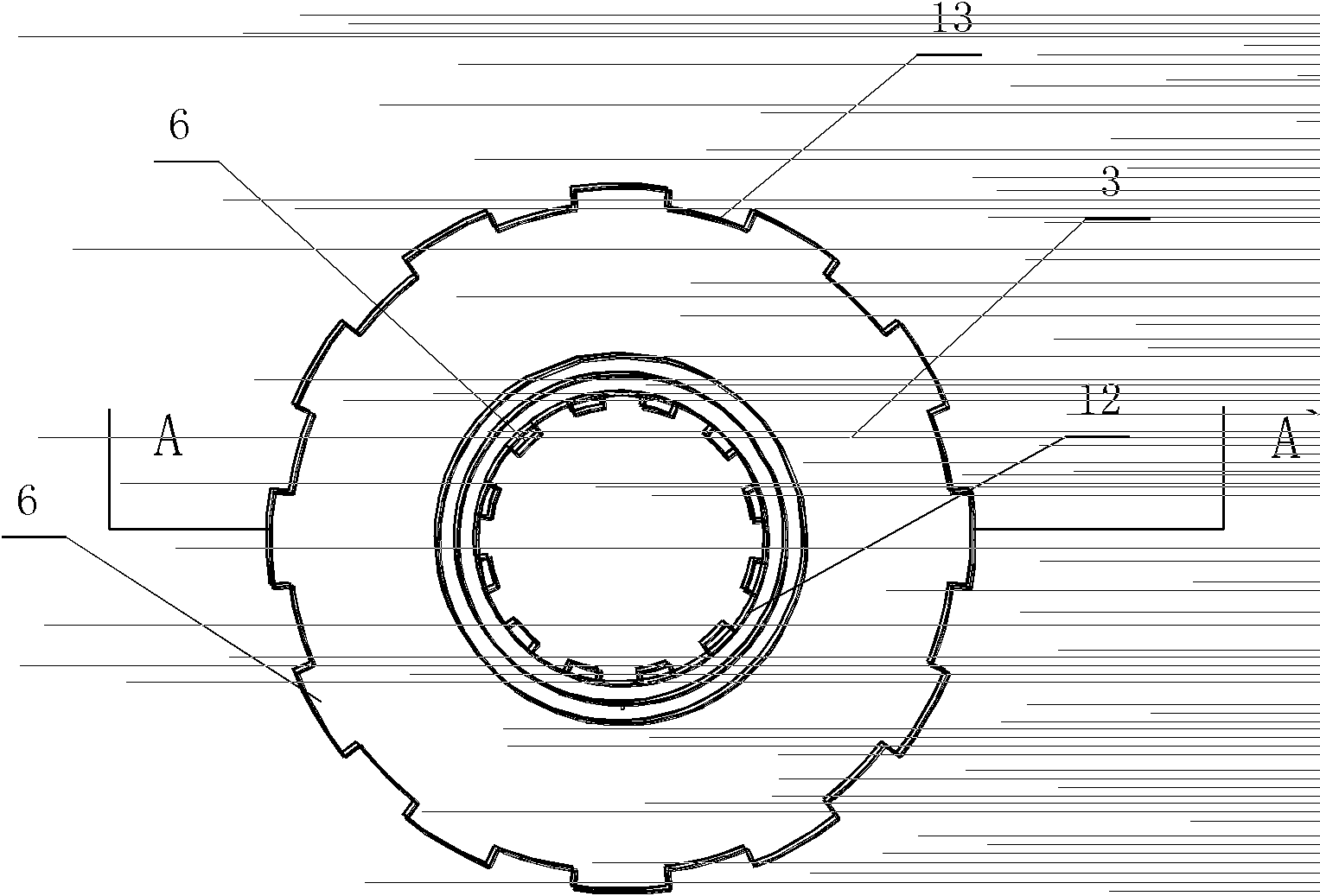

[0034] Such as figure 1 , image 3 with Figure 4 As shown, the elastic coupling for the motor includes a ring shape and coaxial shells 1 , 2 and elastic gears 3 , and a spline inner hole 8 is provided at the center of the shell 1 . The carapace shell 1 is sleeved on the motor shaft 4 through the spline inner hole 8 , and is fixed on the motor shaft 4 through the baffle plate 5 arranged at the end of the motor shaft 4 . A fixing hole 18 is provided at the center of the end of the motor shaft 4 , and the baffle plate 5 is fixed on the shaft end of the motor shaft 4 by fixing bolts 91 . The B housing 2 is arranged between the A housing 1 and the baffle plate 5, and the A housing 1 and the B housing 2 are connected in transmission through the elastic gear 3 arranged therebetween. Specifically, on the inner cylindrical surface 12 of the elastic gear 3 and the radial direction of the outer cylindrical surface 13 are provided with elastic gear radial power transmission teeth 6, a...

Embodiment 2

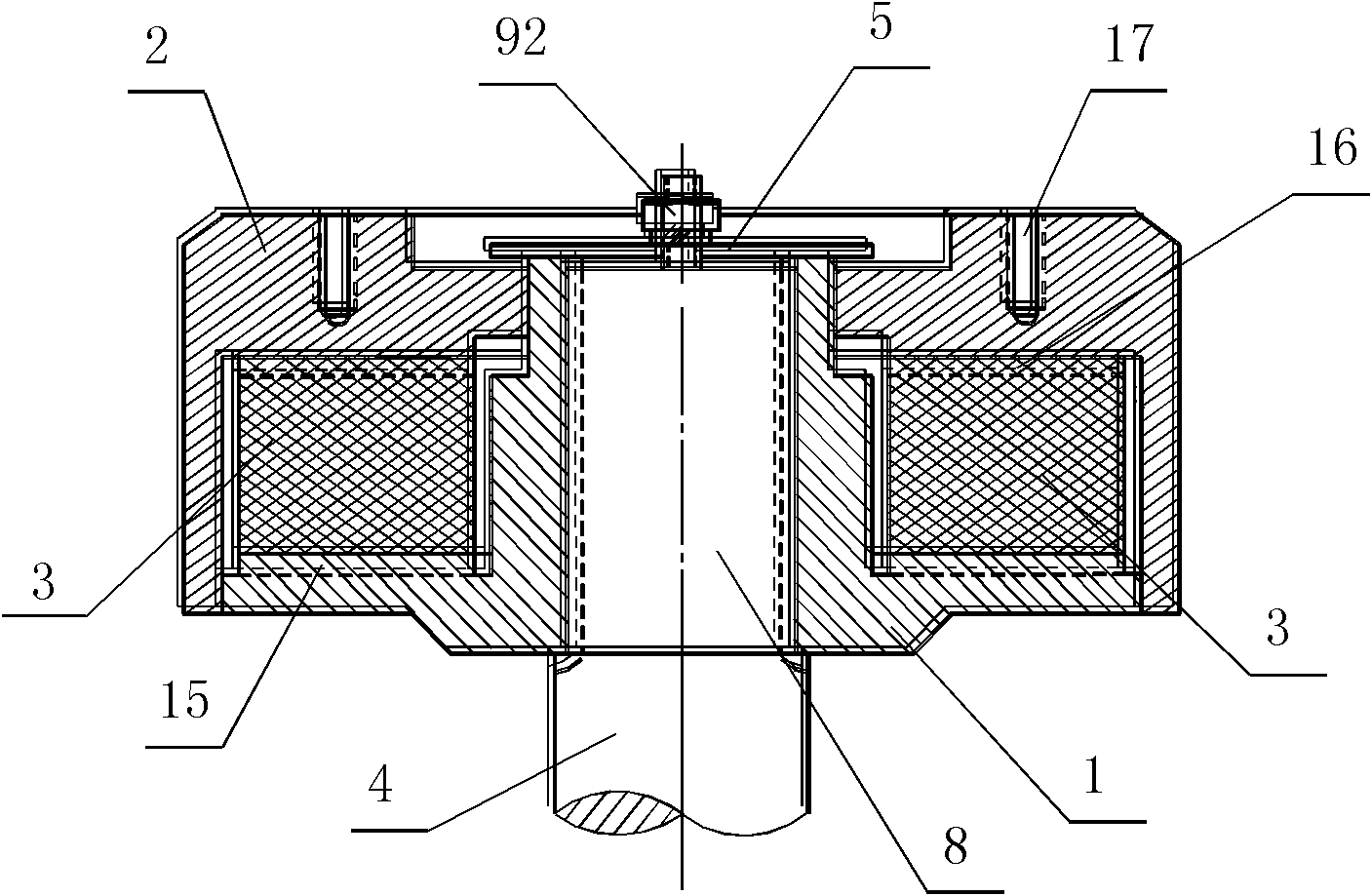

[0041] Such as figure 2 , Figure 5 , Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the transmission between the elastic gear 3 and the shells of A and B in this embodiment is through being arranged on the end face of the elastic gear 3, and with the elastic gear 3 It is realized by the power transmission teeth on the contact surface of the A and B housings whose end faces are in contact. Concretely, the upper cylindrical end surface 19 and the lower cylindrical end surface 20 of the elastic gear 3 are equipped with elastic gear axial force transmission teeth 14 in the axial direction; The contact surfaces of the first case 1 and the second case 2 contacted by 20 are respectively provided with the axial force transmission teeth 15 of the case A and the axial force transmission teeth 16 of the second case, and the upper cylindrical end surface 19 and the lower cylindrical end surface 20 of the elastic gear 3 The axial force transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com