Coded lock cylinder with multiple drive plates

A coded lock core and one-to-one correspondence technology, applied in the field of locks, can solve the problems of increasing the size of the coded lock and the complicated process of opening and closing the lock, and achieve the effects of convenient locking and unlocking, flexible use, and a large amount of codes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

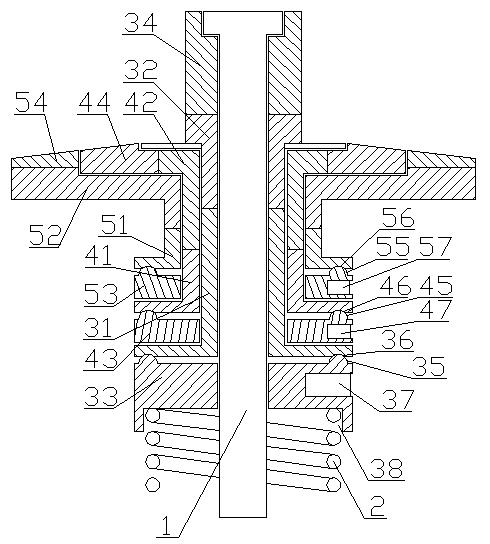

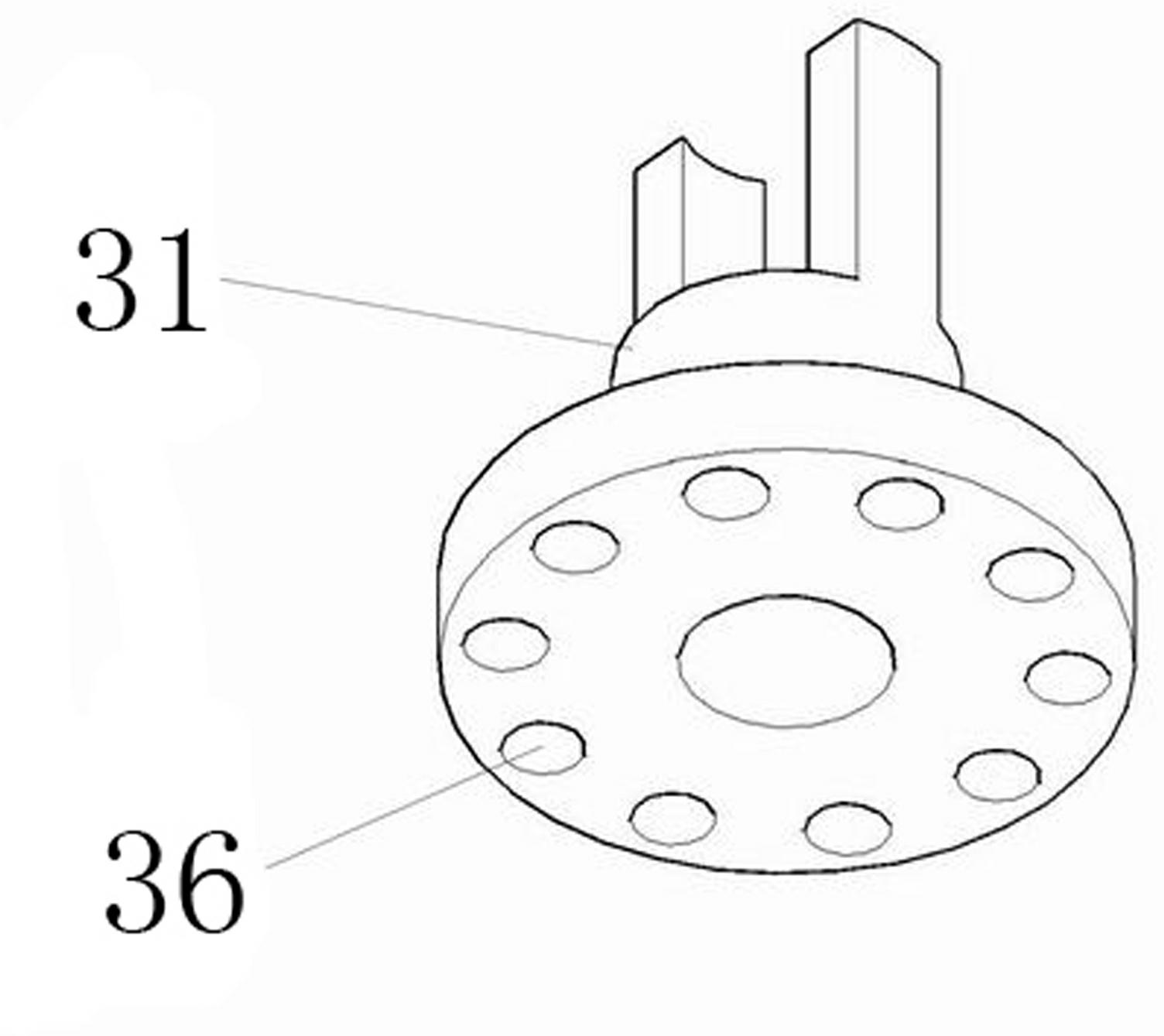

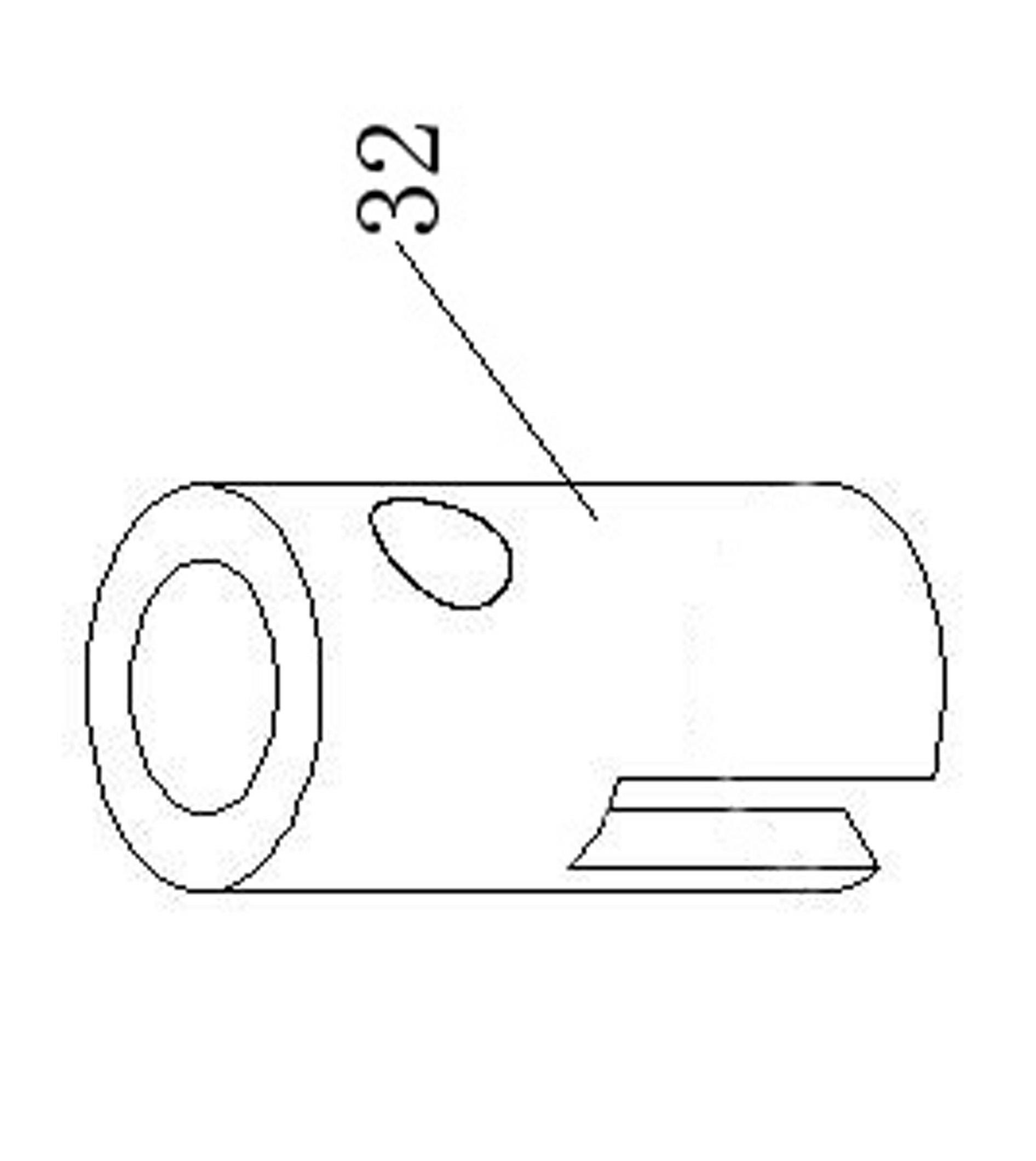

[0017] like Figure 1-4 The shown multi-dial combination lock cylinder includes a first dial mechanism, a second dial mechanism and a third dial mechanism that are set through the central axis 1, and a compression spring 2 is pressed on the bottom of the first dial mechanism . Wherein, the first dial mechanism includes a first telescopic upper shaft 32, a first telescopic lower shaft 31 and a first driven cam 33, ten first grooves 36 are arranged on the bottom surface of the first telescopic lower shaft 31 along the circumferential direction, On the upper end surface of the first driven cam 33, ten first convex points 35 are arranged along the circumferential direction; The shaft 31 and the first driven cam 33 are sleeved on the central shaft 1 sequentially from top to bottom. The upper end of the compression spring 2 is located in the sinking groove 38 of the first driven cam 33. The shafts 31 are engaged with each other by convex-concave gaps, and the ten first grooves 36 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com