Laminated floor slab for steel buildings

A technology for laminated floors and buildings, applied to floors, buildings, building components, etc., can solve problems such as short construction period, long construction period, and difficult hoisting, so as to improve crack resistance and earthquake resistance, excellent earthquake resistance, Guarantee the effect of pouring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

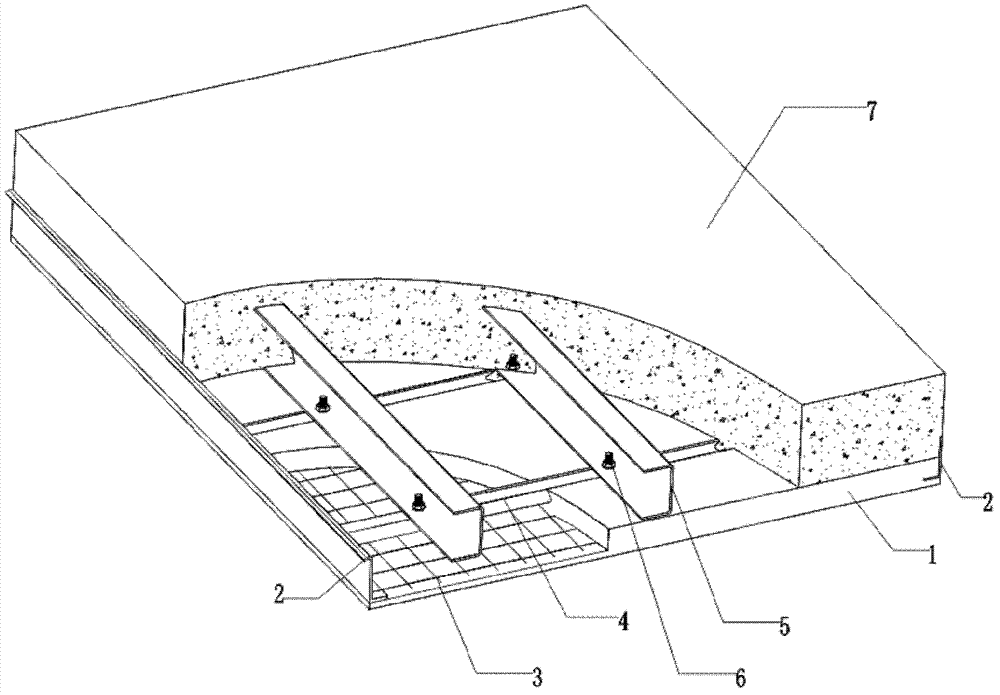

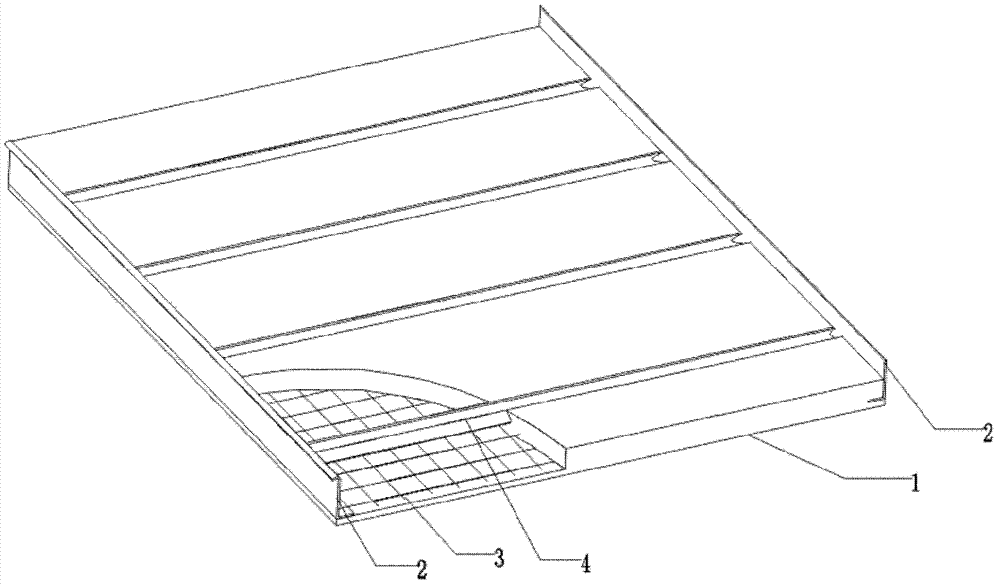

[0018] Prefabricated concrete floor 1: a pair of side plates 2a, 2b are arranged vertically, and the right-angled plates at the bottom are opposite to each other. One side plate 2a has an outer hook edge 2c on the upper edge, and the other side plate 2b has a straight line edge 2d on the upper edge. Such as image 3 As shown, the steel wire mesh 3 is laid between the two side plates 2a, 2b, placed on the right-angled plate surface at the bottom, and connected by self-tapping screws. On the wire mesh 3, connect each other with self-tapping screws, and then cast concrete 1a to form a concrete prefabricated floor 1, see figure 2 , and then place the middle keel 5 longitudinally on the horizontal groove steel belt 4, and connect and fix it with hexagonal bolts 6, such as Figure 4 , 5 , 6 shown. According to the design requirements, the keel 5 can be made of C-shaped stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com