Method for reinforcing kraft with micro-nano inorganic crystal whiskers and kraft

An inorganic whisker, micro-nano technology, applied in the field of kraft paper, can solve the problems of small size of micro-nano inorganic whiskers, easy to agglomerate surface dispersion, large specific surface, etc., achieve excellent comprehensive performance, improve papermaking performance, and enhance the toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

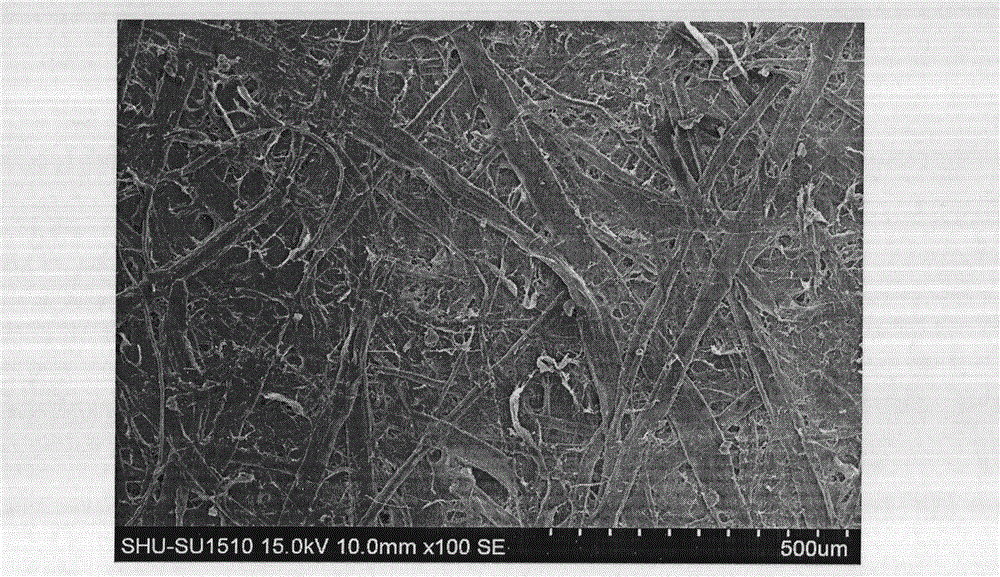

[0040] Embodiment 1: a kind of method of the present invention strengthens kraft paper with micronano inorganic whisker, it comprises the following steps:

[0041] (1) Weigh the micro-nano inorganic whiskers with a mass percentage of 8% to 40%, add the micro-nano inorganic whiskers to water, and disperse by stirring or ultrasonic dispersion so that there are no aggregates in the water. At this time, the micro-nano inorganic crystals The whiskers are suspended in water in the form of single fibers, forming a whisker suspension;

[0042] (2) Weighing the modified sol with a mass percentage of 1% to 20%, adding the modified sol to the whisker suspension, and modifying by stirring or ultrasonic to prepare the modified whisker suspension;

[0043] (3) Weighing dry pulp with a mass percentage of 50% to 90%, adding the dry pulp to water for soaking and beating to a certain beating degree, the concentration of the slurry is 1%, adding the modified whisker suspension to the slurry , a...

Embodiment 2

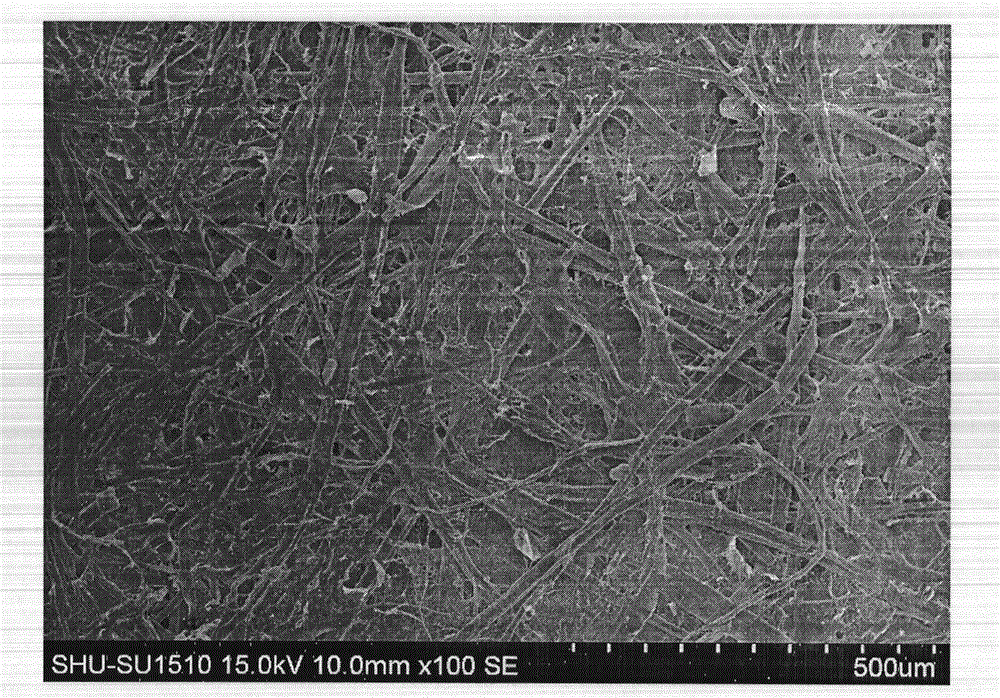

[0061] Embodiment 2: The method of reinforcing kraft paper with micro-nano inorganic whiskers in this embodiment is basically the same as that of kraft paper in Example 1, the difference being that the raw material composition and mass percentage of the kraft paper are:

[0062]

[0063] In this embodiment, the balance is trace moisture and impurities.

Embodiment 3

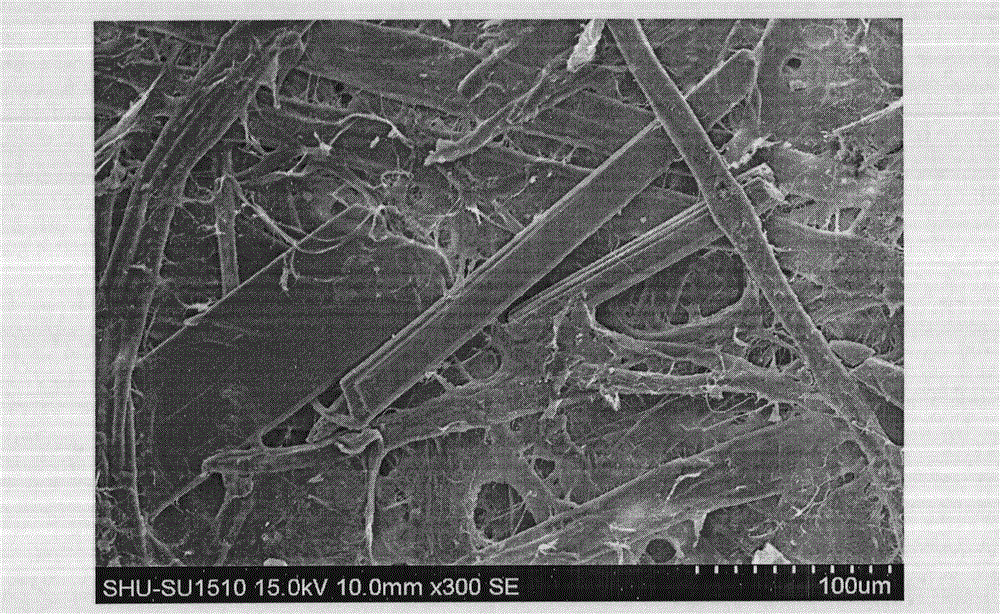

[0064] Embodiment 3: The method of reinforcing kraft paper with micro-nano inorganic whiskers of the present embodiment is basically the same as that of kraft paper in Examples 1 and 2. The difference is that the raw material composition and mass percentage of the kraft paper are:

[0065]

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| ionicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com