Device for sealing upper cover of mining clinker car

A sealing device and clinker technology, applied in the direction of freight vehicles, motor vehicles, load coverage, etc., can solve the problems of comprehensive control of mine dust, clinker dust pollution of pipelines, track cables, and employee health hazards, etc. problems, to achieve the effect of reducing the frequency of dust removal and maintenance, saving manual output, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

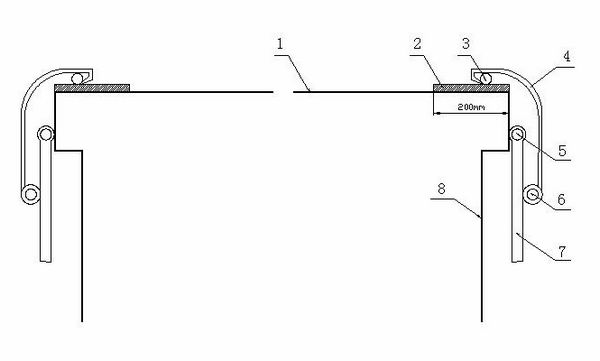

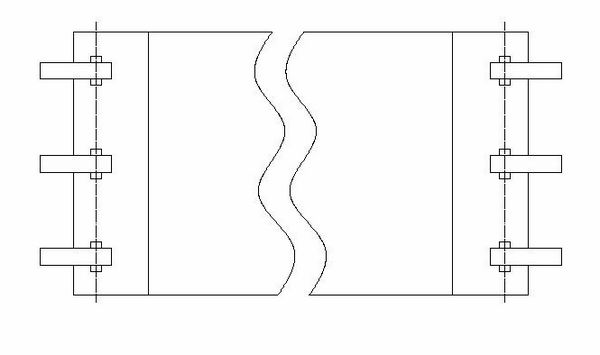

[0020] Such as Figure 1-2 As shown, 1. The sealing device for the upper cover of the mine clinker truck is composed of a cover and a plurality of cover locking devices. The main material of the cover is a high-strength rubber 1, and the size of the rubber 1 is the same as that of the mine clinker The outer contour dimensions of the upper opening of the compartment 8 of the car are the same, and a steel plate 2 with a width of 200 mm and a thickness of 5 mm is riveted at both ends of the rubber 1 respectively. The cover locking device described above is composed of a handle hinge seat, a handle 7, a locking hook 4 and a locking body 3. The handle hinge seat is arranged on the outside of the mine clinker car compartment 8, and the handle 7 passes through the handle hinge shaft 5. Hinged on the hinge seat of the handle, the locking hook 4 is hinged to the middle part of the handle 7 through the hinge shaft of the locking hook, and the locking body 3 is arranged on the upper part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com