Spring clip

A spring clip and clamping block technology, applied in the field of spring clips, can solve the problems of reducing the degree of freedom, increasing the cost, and higher material requirements, and achieving the effect of reducing processing costs, low costs, and low material requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

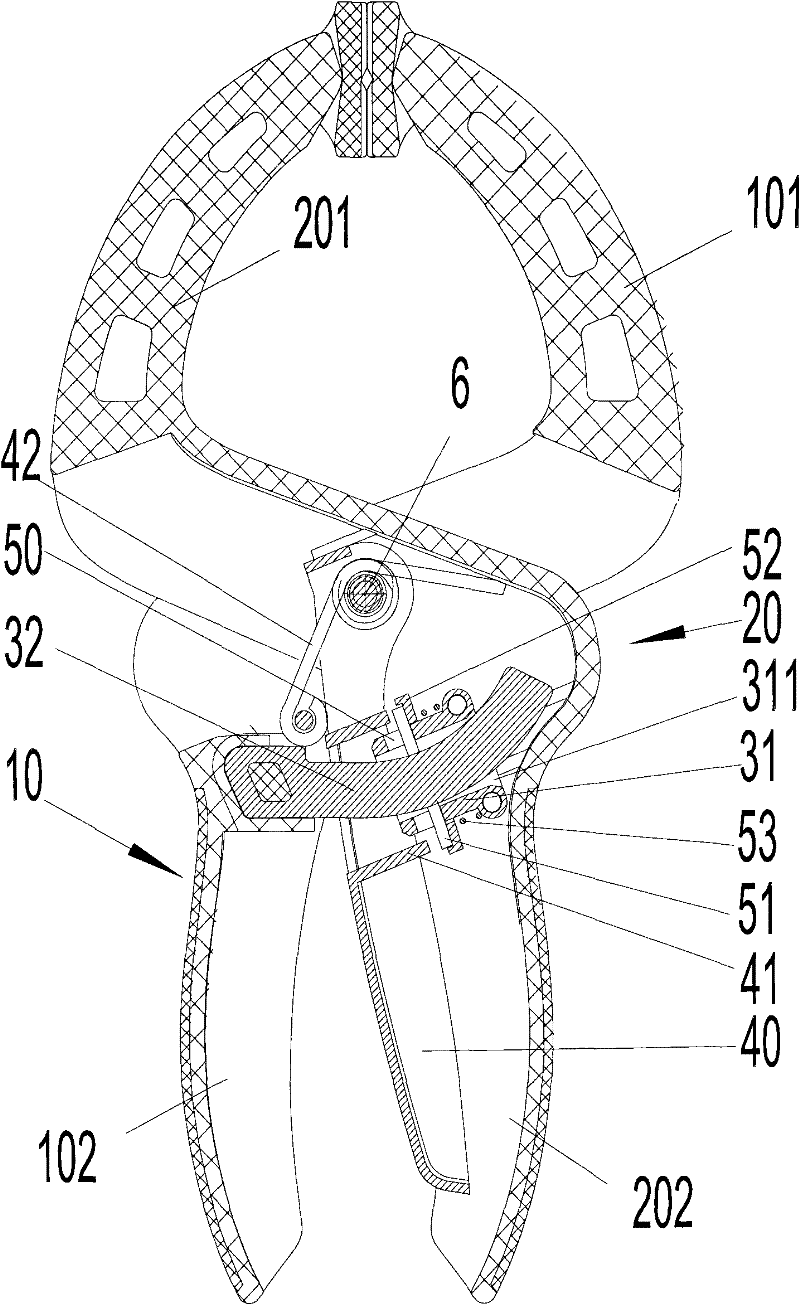

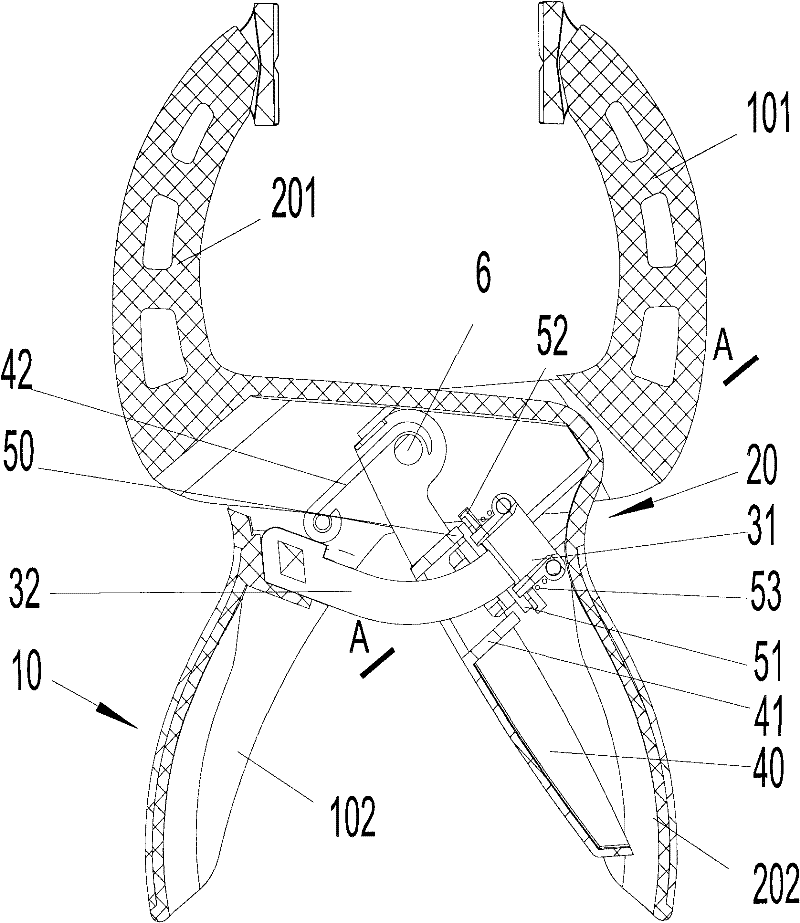

[0047] Such as figure 1 and 2 As shown, a specific embodiment of the spring clip of the present invention includes a first body 10, a second body 20, and a first pivot that pivotably couples the first body 10 and the second body 20 together 6. The first main body 10 and the second main body 20 respectively include a gripping portion 102 , 202 and a clamping portion 101 , 201 . The clamping parts of the two main bodies 10, 20 can also be respectively provided with movable chucks, so as to facilitate clamping.

[0048] The first pivot 6 is made of screws, bolts, rivets, etc., and is located in the middle of the first body 10 and the second body 20. The lower half of the first body 10 and the second body 20 can respectively form a semi-open cavity. And it can be covered with a soft covering layer on the outside, such as leather, artificial leather, plastic or rubber.

[0049] The spring clip of the present invention also includes a locking mechanism. The locking mechanism in...

Embodiment 2

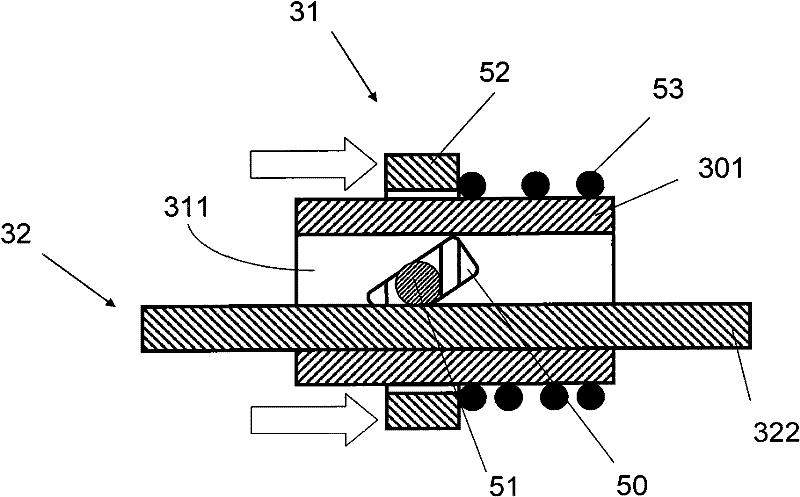

[0069] The structure of another specific embodiment of the spring clip of the present invention is similar to that of Embodiment 1, the difference lies in its locking mechanism. Such as Figure 4 As shown, two sets of strip-shaped holes 50 and 50' are provided in the clamping block 301 of the locking mechanism. Two needle rollers 51 and 51' whose two ends are exposed in the bar-shaped hole are arranged in the bar-shaped hole. The needle roller 51 and the clip free end 322 form a pair of friction pair elements, and the needle roller 51' and the clip free end 322 form another set of friction pair element pairs. The two sets of friction pairs work together to realize the stepless locking function of the spring clip of the present invention.

[0070] The working principle of this embodiment is the same as that of the first embodiment, so it will not be repeated.

Embodiment 3

[0072] The structure of another specific embodiment of the spring clamp of the present invention is similar to that of Embodiment 1, the difference is that the second friction pair part of the locking mechanism is replaced with a new second friction pair part 131, such as Figure 5 The shown clamping block 1301 , wedge block 151 , wedge block fixing ring 152 and elastic element 153 are composed. The two sides of the clamping block 1301 are provided with wedge-shaped block guide grooves 150 , and the wedge-shaped block guide grooves 150 are provided with wedge-shaped block 151 whose two ends are exposed to the wedge-shaped block guide grooves 150 . The wedge block 151 constitutes a second friction pair element. An elastic element 153 is arranged on the outside of the clamping block 1301 , and a wedge-shaped block fixing ring 152 is used to push the wedge-shaped block 151 to move along the wedge-shaped block guide groove 150 toward the direction close to the free end 322 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com